Addition In the world of engineering, mechanical design engineers play a crucial role in shaping the functionality and efficiency of various products and systems. At eTAZ Systems, a leading engineering firm specializing in control and electronics engineering, mechanical design engineers are essential for delivering high-quality solutions tailored to our clients’ needs. This article explores the role of a mechanical design engineer, their responsibilities, and the expertise they bring to eTAZ Systems, along with frequently asked questions (FAQs) to provide a comprehensive understanding of their role.

What is a Mechanical Design Engineer?

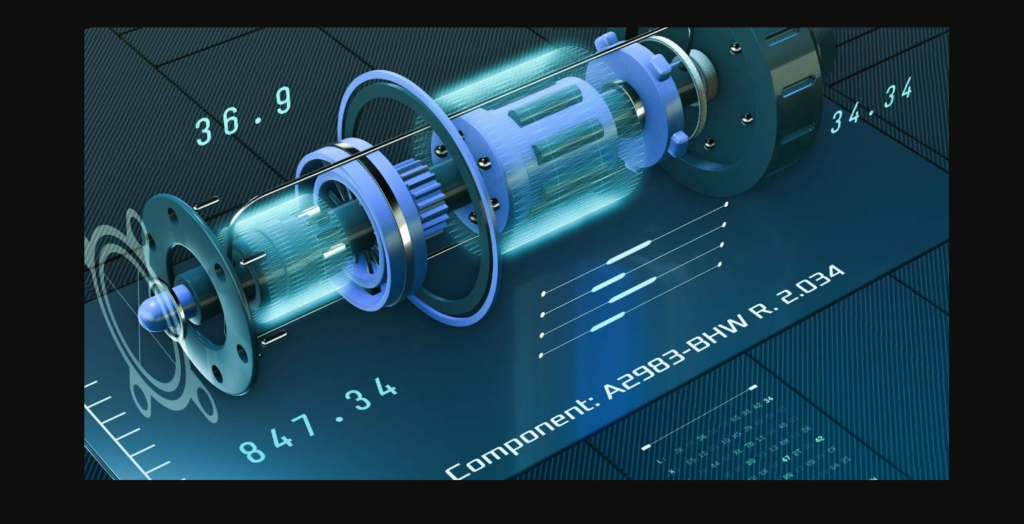

A mechanical design engineer is a professional who uses principles of mechanical engineering to design, develop, and test mechanical systems and components. They create detailed design plans, analyze performance, and ensure that they manufacture products efficiently and meet quality standards.

Key Responsibilities: Furthermore Conceptual Design: Mechanical design engineers develop initial concepts based on client requirements, project specifications, and industry standards. They use CAD (Computer-Aided Design) software to create detailed drawings and models.

Design Analysis: They perform simulations and analyses to ensure the design can withstand operational stresses and conditions. This includes stress analysis, thermal analysis, and vibration analysis.

Prototyping: Similarly Mechanical design engineers often oversee the creation of prototypes to test and validate their designs. They work closely with manufacturing teams to refine and iterate the design based on testing feedback.

Documentation: Nevertheless Creating comprehensive documentation for designs, including technical drawings, specifications, and manufacturing instructions, is a crucial part of their role.

They work with other engineers, designers, and stakeholders to integrate mechanical components with electrical and software systems.

Quality Assurance: Ensuring that designs meet industry standards and regulations, and conducting inspections and tests to verify the functionality and safety of products.

However Problem-Solving: Addressing design and manufacturing issues, troubleshooting problems, and implementing effective solutions.

Expertise at eTAZ Systems

At eTAZ Systems, our mechanical design engineers are pivotal in delivering cutting-edge solutions across various domains, including IoT, home automation, and power systems. Here’s how our team of mechanical design engineers stands out:

Advanced Tools and Techniques: Our engineers use state-of-the-art CAD software, simulation tools, and rapid prototyping technologies to ensure precision and efficiency in their designs.

Cross-Disciplinary Knowledge: With a deep understanding of control systems, electronics, and mechanical systems, our engineers excel in creating integrated solutions that meet complex project requirements.

Experience and Innovation: Our team’s extensive experience and commitment to innovation enable us to tackle challenging projects and deliver solutions that push the boundaries of technology.

Client-Centric Approach: We prioritize our clients’ needs and work closely with them to develop customized solutions that align with their goals and expectations.

FAQs

To become a mechanical design engineer, what qualifications do you need?

To become a mechanical design engineer, you typically need to earn a bachelor’s degree in mechanical engineering or a related field. Advanced positions may require a master’s degree or additional certifications. Proficiency in CAD software and strong analytical skills are also essential.

Which software tools do mechanical design engineers commonly use?

Similarly Mechanical design engineers commonly use CAD software such as SolidWorks, AutoCAD, and CATIA. Simulation and analysis tools like ANSYS and MATLAB are also used to evaluate design performance.

3. How does a mechanical design engineer collaborate with other engineering disciplines?

Addition Mechanical design engineers collaborate closely with electrical engineers, software developers, and other specialists to ensure that they integrate mechanical components seamlessly with other systems. Effective communication and teamwork are crucial for successful interdisciplinary collaboration.

4. What industries employ mechanical design engineers?

Moreover Mechanical design engineers are employed in various industries, including automotive, aerospace, consumer electronics, industrial machinery, and energy. Their skills are applicable wherever mechanical systems and components are designed and manufactured.

5. How does eTAZ Systems ensure the quality of mechanical designs?

At eTAZ Systems, we implement rigorous quality assurance processes, including design reviews, prototype testing, and compliance with industry standards. Our engineers commit to delivering high-quality designs that meet or exceed client expectations.

6. What are some examples of projects handled by mechanical design engineers at eTAZ Systems?

Our mechanical design engineers have worked on a range of projects, including IoT-enabled devices, automated systems for home and industrial applications, and advanced power systems. Each project benefits from our team’s expertise in designing innovative and reliable solutions.

7. How does eTAZ Systems stay ahead in mechanical design engineering?

Nevertheless We stay ahead by investing in the latest technologies, continuously updating our skillset, and fostering a culture of innovation. Our engineers are encouraged to pursue ongoing education and participate in industry conferences to stay current with emerging trends and advancements.

8. What role does prototyping play in mechanical design engineering at eTAZ Systems?

Furthermore Contrast Prototyping is a critical step in our design process. It allows us to test and refine designs before full-scale production, ensuring that any issues are addressed early. This iterative process helps us deliver reliable and high-performance products.

Conclusion

Mechanical design engineers at eTAZ Systems are at the forefront of innovation, utilizing their expertise to create high-quality and efficient mechanical systems. Their role is essential in delivering solutions that meet the complex needs of our clients and drive technological advancements. likewise leveraging advanced tools, interdisciplinary knowledge, and a client-centric approach, our mechanical design engineers contribute significantly to our success as a leading engineering firm.