Therefore In the world of embedded systems, the Controller Area Network (CAN) protocol has set up itself as a robust and dependable communique trendy, specially within the car, industrial, and aerospace sectors. It allows different devices (also known as nodes) inside a community to talk with out the need for a imperative controller. In this newsletter, we are able to explore the intricacies of CAN protocol hardware design, the key additives involved, and how eTAZ Systems gives you present day answers for such designs.

What is CAN Protocol?

The CAN protocol is a message-based protocol that permits microcontrollers and gadgets to talk with every different in applications with out a bunch pc.Bosch advanced it in the Eighties, mainly for the automotive industry, and standardized it as ISO 11898.

Key Features of CAN Protocol:

Multi-grasp machine: Each node can send and get hold of messages, and there is no unmarried master that controls conversation.

Error detection: CAN gives robust blunders detection and coping with mechanisms, making it reliable in important systems.

Priority-based get admission to: Each message has a priority degree that allows avoid conflicts when a couple of nodes try to speak concurrently.

CAN Protocol Hardware Components

“When designing hardware for the CAN protocol, engineers select the proper components and ensure that the device is optimized for noise immunity, speed, and reliability. Below are the core additives concerned in CAN hardware layout:

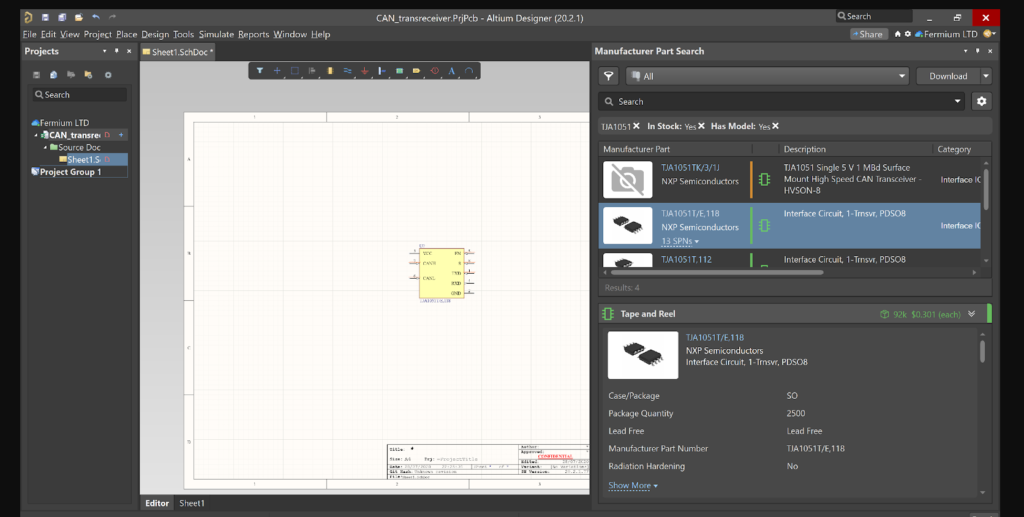

1. CAN Transceiver

The CAN transceiver is the interface between the CAN controller and the physical bus. It converts the digital records from the CAN controller into the differential signal used on the CAN bus and vice versa.

High-speed CAN transceivers: These function at speeds up to at least one Mbps.

Low-speed fault-tolerant transceivers: These operate at slower speeds (as much as 125 Kbps) but provide greater reliability in harsh environments.

2. CAN Controller

In most instances, microcontrollers include built-in CAN controllers, but you can also use separate controller ICs for extra flexibility.

Integrated CAN controllers: Automotive microcontrollers usually have these, which lowers layout complexity.

Standalone CAN controllers: Commercial and aerospace applications generally use these when they require specialized control.

4o mini

Three. Microcontroller

The microcontroller processes the records being sent or obtained over the CAN bus. For high-performance applications, selecting a microcontroller with ok clock pace and reminiscence is crucial to make sure easy operation.

Designing CAN Protocol Hardware

Designing hardware for the CAN protocol calls for cautious planning to ensure that the gadget is optimized for noise immunity, speed, and reliability. Below are the important thing concerns for designing CAN protocol hardware:

1. PCB Layout Design

However The PCB layout performs a important position in ensuring the reliability and overall performance of the CAN community. Here are the quality practices for PCB layout in CAN protocol hardware layout:

Short trace lengths: Minimize trace lengths for signal integrity.

Differential pair routing: Ensure the CANH and CANL signals are routed as differential pairs to lessen electromagnetic interference (EMI).

Shielding: In noisy environments, it’s important to use protecting or ground planes to defend the CAN indicators from external noise.

2. Clock Accuracy

Accurate clocking is vital for the CAN controller to synchronize with the bus. A clock supply with low jitter and minimal frequency glide is essential for keeping community integrity.

Three. EMC Considerations

CAN systems are used in environments with large electromagnetic interference (EMI), together with car and industrial settings. To limit EMI, the subsequent measures must be implemented:

Use of commonplace-mode chokes: These assist suppress noise on the CAN bus.

Grounding strategies: A right grounding scheme guarantees that noise does no longer have an effect on the CAN transceiver or controller.

Applications of CAN Protocol Hardware Design

1. Automotive Systems

In modern-day cars, CAN networks are used to attach numerous subsystems, including engine control, transmission manage, and braking structures. Especially properly-designed CAN protocol hardware ensures easy operation and conversation among those critical components.

2. Industrial Automation

CAN networks are employed in industrial environments to govern equipment and method systems. A fault-tolerant design is critical in these environments to save you verbal exchange disasters that could bring about downtime or equipment damage.

Three. Medical Devices

Additionally Medical system, inclusive of diagnostic tools and monitoring gadgets, also rely on CAN networks. In these packages, errors-free communique is vital to make certain correct records switch and patient protection.

4. Aerospace

In the aerospace enterprise, the CAN protocol is used for communication between diverse avionics structures. The layout of CAN hardware in aerospace packages must meet stringent necessities for reliability, fault tolerance, and EMI immunity.

FAQs: CAN Protocol Hardware Design

1. What is the role of a CAN transceiver within the hardware layout?

Addition CAN transceiver converts the differential alerts from the CAN bus into virtual information for the microcontroller or CAN controller. Illustrate ensures that data is well transmitted and acquired at the bodily bus.

2. Why are termination resistors critical in CAN hardware design?

Termination resistors (commonly 120Ω) are located at both ends of the CAN bus to save you sign reflections, making sure that the alerts are correctly transmitted and decreasing conversation errors.

Three. What type of microcontrollers are fine for CAN hardware layout?

Microcontrollers with integrated CAN controllers are best, especially for car packages. Popular choices include the ones from STMicroelectronics, Microchip, and Texas Instruments, which offer strong CAN verbal exchange capabilities.

4. How are you able to ensure mistakes-free conversation in CAN hardware?

Error-unfastened communique in CAN hardware can be completed by using following excellent practices in PCB format, using accurate clock sources, implementing right mistakes-handling mechanisms, and ensuring that the gadget is designed to minimize EMI and noise interference.

5. What are the challenges of designing CAN protocol hardware for car programs?

Challenges consist of ensuring fault tolerance, meeting electromagnetic compatibility (EMC) requirements, and managing bus loading as greater nodes are added to the CAN community.

6. How does eTAZ Systems assist with CAN protocol hardware design?

Furthermore eTAZ Systems, we specialize in designing robust and reliable CAN hardware systems tailor-made to automobile, industrial, and aerospace wishes. We use latest gear and design practices to ensure seamless integration and fault tolerance in every undertaking.

7. What are the extraordinary styles of CAN networks?

There are several kinds of CAN networks, together with High-Speed CAN (used in car networks for speedy verbal exchange) and Low-Speed Fault-Tolerant CAN (utilized in environments where reliability is greater critical than velocity).

Conclusion

moreover CAN protocol hardware layout is a critical part of cutting-edge embedded systems, making sure robust, dependable, and error-unfastened verbal exchange in numerous industries, from automobile to aerospace. At eTAZ Systems, we bring years of knowledge in designing CAN networks tailored to fulfill the best requirements of overall performance and reliability. Whether it is a easy network or a complex multi-node device, our solutions make certain smooth conversation and fault-tolerant design.