In the world of load cell technology, the Jr S Beam load cell is a popular choice for many applications due to its accuracy and reliability. In this blog post, we will explore the intricacies of Jr S Beam load cells, Indeed their role in eTAZ systems, installation tips, maintenance challenges, real-world applications, and future trends in load cell technology.

Understanding the Basics of Jr S Beam Load Cells

Engineers have designed the Jr S Beam load cell, a pivotal component in precision measurement technology, to accurately gauge both tension and compression forces. Renowned for its superior precision and robustness, it serves as an indispensable tool across a plethora of sectors including manufacturing, construction, and aerospace. The essence of its operation lies in its ability to transform physical force into a quantifiable electrical output, Firstly facilitating easy and precise data analysis. This transformation process is pivotal for industries that demand high accuracy in force measurement, enabling them to monitor and analyze forces with unparalleled precision. Essential to the success of its application is the quality of its design, then which ensures that the Jr S Beam load cell remains a reliable choice for tasks demanding the highest levels of accuracy and durability.

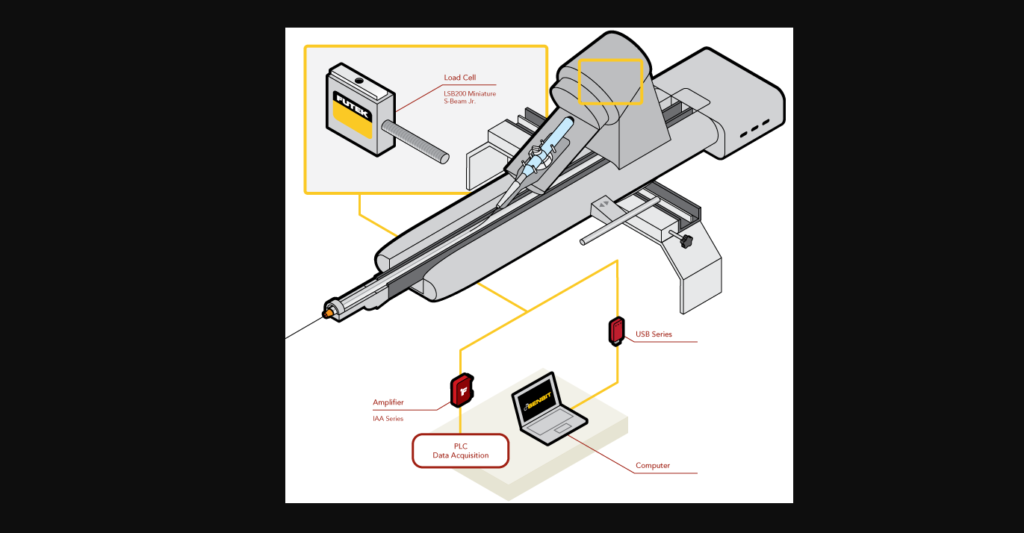

The Role of Jr S Beam Load Cells in eTAZ Systems

eTAZ systems, standing for electronic Totalizer and Analyzer Zones, incorporate Jr S Beam load cells as pivotal components for precision measurements. These innovative systems employ across diverse industries, from agricultural operations to high-stakes aerospace endeavors, where the measurement and analysis of weight, force, and pressure are critical for operational success. The integration of Jr S Beam load cells into eTAZ systems facilitates the accurate monitoring of processes, translating complex force data into actionable insights. This capability is essential for maintaining the efficacy and safety of automated systems, optimizing product quality, and enhancing production efficiency. By leveraging the precise and reliable data provided by Jr S Beam load cells, eTAZ systems empower operators and engineers to fine-tune their processes in real-time, overall respond swiftly to any discrepancies, and uphold stringent standards of accuracy and reliability in measurement-intensive environments.

Installation Tips for Optimal Performance

For those incorporating Jr S Beam load cells into their measurement systems, ensuring correct installation is paramount for achieving the highest level of performance. Start by selecting an installation site that minimizes exposure to environmental stressors such as vibration, extreme temperatures, or corrosive elements, all of which can affect the load cell’s accuracy over time. When mounting the load cell, ultimately. ensure that you securely fasten it and precisely align it to the load direction; misalignment can cause measurement errors and reduce the cell’s life due to uneven stress distribution.It’s also critical to employ the right mounting accessories recommended by the manufacturer, such as load buttons or rod ends, to aid in the proper transmission of force to the load cell. Additionally, integrating a protective enclosure can shield the device from harmful environmental impacts, further preserving its functionality and accuracy.

Navigating the Challenges of Jr S Beam Load Cell Maintenance

Maintaining the precision and durability of Jr S Beam load cells necessitates a proactive approach to combat common challenges. Environmental conditions, such as fluctuations in temperature and levels of humidity, significantly influence performance. Protecting these devices from such conditions can prevent the degradation of materials and the loss of accuracy. Regular inspection for signs of wear and tear is crucial, as is the implementation of preventative maintenance routines. This might include cleaning the load cell and checking for any corrosion, ensuring all connections remain secure, and verifying the calibration. Calibration is particularly important, as it adjusts for any natural drift in measurements that might occur over time, ensuring continued accuracy. It’s also beneficial to monitor the load cell’s output signal regularly for signs of instability or irregularities, which could indicate the need for maintenance or calibration adjustments.

Real-World Applications of Jr S Beam Load Cells

The versatility of Jr S Beam load cells spans across various sectors, demonstrating their critical role in diverse applications. In the manufacturing domain, these load cells play a crucial part in ensuring quality control by providing precise weight measurements of components, thereby safeguarding product consistency. Within the realm of agricultural technology, Jr S Beam load cells contribute to the optimization of machinery, such as feed dispensing equipment, by facilitating accurate load dispensing, enhancing efficiency, and reducing waste. The construction industry benefits from their capacity to monitor tension in support structures, enabling engineers to ensure the safety and stability of buildings and bridges. In aerospace, they are instrumental in testing materials and components under extreme forces, simulating conditions these materials will face in real-world scenarios, thus verifying their integrity and performance. Moreover, their application in medical devices for force feedback mechanisms underscores their importance in delicate procedures, ensuring precise control.

Future Trends in Load Cell Technology and the Place of Jr S Beam

The horizon of load cell technology is witnessing transformative shifts, with innovations aimed at enhancing efficiency, accuracy, and integration capabilities. IoT (Internet of Things) has enabled load cells, which allow remote monitoring and data analysis, thus ushering in a new era of predictive maintenance and operational intelligence. Furthermore, miniature load cells are poised to revolutionize the measurement of force in space-constrained applications by offering high precision in significantly smaller packages. The Jr S Beam load cell, known for its robust design and proven reliability, is well-equipped to adapt to these technological advancements. Its compatibility with smart technologies and potential for miniaturization make it a vital component in the future landscape of load measurement. Further, advancements in material science promise to enhance the durability and environmental resistance of load cells, ensuring the Jr S Beam can meet the demands of even more challenging applications.

Conclusion

As we have journeyed through the intricate landscape of Jr S Beam load cell technology, its foundational role in the realms of precision measurement and the innovation-driven eTAZ systems has been vividly illuminated. Emphasizing its installation, the pivotal maintenance strategies, and its versatile real-world applications lays bare the technology’s multifaceted significance. The exploration into the upcoming trends that could reshape the load cell technology landscape further underscores the adaptability and potential growth trajectory of the Jr S Beam load cells. These insights collectively spotlight the essential nature of embracing both the current capabilities and forthcoming advancements in load cell technology. In doing so, industries across the spectrum can continue to rely on these devices for the critical accuracy and reliability required in today’s increasingly automated and data-driven operational environments.

FAQs

How does an S-beam load cell work?

In the realm of precision measurement and industrial weighing, the S-beam load cell stands out for its versatility and accuracy. “Various applications, ranging from industrial machinery to medical devices, widely use this type of load cell, recognized for its distinctive ‘S’ shape. Understanding how an S-beam load cell works is essential for leveraging its benefits in accurate force and weight measurement.

What a load cell

The most common type is the strain gauge load cell, which measures deformation under load, changing its electrical resistance proportionally. “The strain gauge load cell measures deformation under load and changes its electrical resistance proportionally. You can then use this signal to determine the weight or force applied.”

If you need specific information from the uploaded file, please let me know

how does a load cell work

How Does a Load Cell Work?

The most common type, the strain gauge load cell, operates based on the principle of deformation of a material under load. Here’s a detailed explanation of how it works:

Components of a Load Cell

- Strain Gauges: Thin resistive foil elements that change resistance when deformed.

- Elastic Element (Beam): A structural component that deforms under load.

- Wheatstone Bridge Circuit: An electrical circuit used to measure the change in resistance.

- Wiring and Connectors: These components transmit the electrical signal.

- Protective Housing: Encases and protects the internal components from environmental factors.

Working Principle

1. Application of Load

When a force or load is applied to the load cell, it causes the elastic element (typically a metal beam) to deform slightly. This deformation is the key to how the load cell measures force.

what is load cell?

It primarily uses strain gauges attached to a deformable material. When a load is applied, the material deforms, causing a change in electrical resistance. This change is measured and converted into a readable output, making load cells essential in weighing systems, industrial applications, and force measurement tasks.

Pingback: Professional Hardware Design offerings with eTAZ Systems -