PCB design manner start with layout and verification and retain thru the fabrication of the circuit boards by eTAZ systems

Design Preparation

Finalizing the PCB design: Ensuring the layout meets all necessities and constraints.

Generating Gerber documents: Converting the design into a format that can be utilized by fabrication equipment.

Design for Manufacturability (DFM): Reviewing the layout for any capability production issues and optimizing it for fabrication.

Material Selection:

Substrate cloth: Choosing the perfect material based totally on elements which include electrical residences, thermal conductivity, and value.

Copper foil: Selecting the thickness and type of copper foil based totally at the design necessities.

Solder mask and silkscreen: Determining the type and shade of the solder masks and including necessary markings and labels.

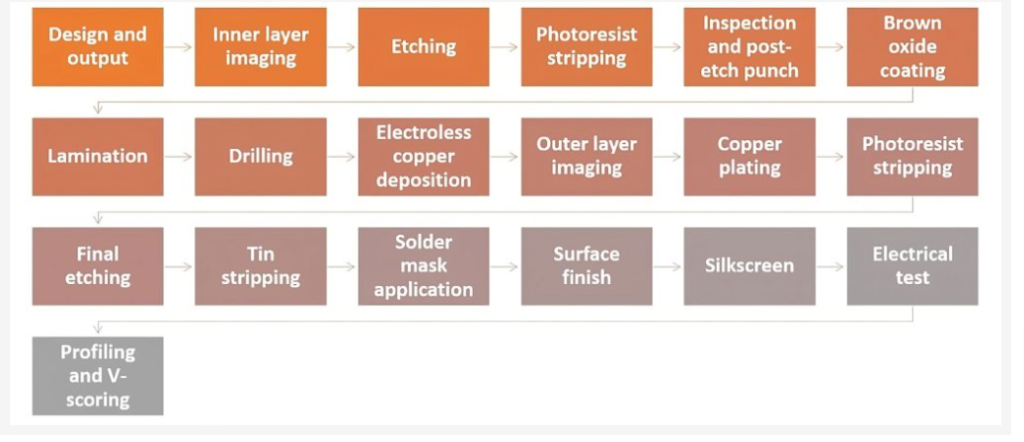

PCB Manufacturing Processes

Substrate coaching: Cleaning and treating the substrate material to ensure proper adhesion of copper and other layers.

Copper deposition: Applying a skinny layer of copper onto the substrate the use of techniques like electroless plating or electroplating.

Photoresist utility: Coating the copper floor with a photosensitive fabric called photoresist.

Photolithography: Exposing the photoresist to UV mild via a photomask, which defines the circuit pattern.

Etching: Removing the unwanted copper the usage of chemical etchants, leaving at the back of the preferred circuit strains.

Solder mask application: Applying a layer of solder masks to shield the copper lines and offer insulation.

Silkscreen printing: Adding aspect labels, trademarks, and other markings the use of a silkscreen printing process.

Surface finish: Applying a shielding coating to the exposed copper pads to save you oxidation and facilitate soldering.

Quality Control and Testing

Visual inspection: Checking for any defects or inconsistencies in the PCB board.

Electrical testing: Verifying the connectivity and capability of the circuit the usage of automatic trying out device.

Impedance testing: Ensuring the impedance values of critical strains meet the layout specifications.

Reliability testing: Subjecting the PCB to environmental pressure checks to assess its sturdiness and overall performance below diverse conditions.

PCB Assembly

Component placement: Mounting electronic components onto the PCB the usage of automatic pick-and-vicinity machines or guide assembly.

Soldering: Joining the additives to the PCB using soldering techniques inclusive of reflow soldering or wave soldering.

Inspection and trying out: Verifying the excellent of the solder joints and undertaking useful exams to make sure right meeting.

Advanced PCB Fabrication Techniques

Multilayer PCBs: Fabricating PCBs with a couple of layers for complex circuit designs.

High-density interconnect (HDI) PCBs: Utilizing advanced techniques to reap better component density and sign integrity.

Flex and rigid-flex PCBs: Manufacturing flexible PCBs for programs that require bending or folding.

Conclusion

PCB board fabrication is a complex manner that requires careful interest to element and adherence to enterprise requirements. By knowledge the steps worried and thinking about factors inclusive of cloth selection, production tactics, and first-class manage, engineers can make certain the manufacturing of super PCBs that meet the design necessities. Collaboration with skilled PCB producers and continuous development in fabrication techniques will in addition decorate the efficiency and reliability of the PCB fabrication manner.

Contact Us.

For greater records about our PCB Board Fabrication

services or to talk about your undertaking requirements, please attain out to us at:

Office: #nine, First ground, Business Incubation Center SSC, University of Engineering and Technology, Lahore.

Phone: +923234767694

Email: info@etazsystems.Com

At eTAZ Systems, we’re devoted to handing over excellent PCB design answers that meet your specific needs and help you obtain your venture goals.