Bending beam load cells are a popular preference in various industries for measuring weight and force accurately. These devices play a essential role in digital truck scales, hopper scales, and different programs that require unique weight measurements. In this blog put up, we are able to delve into the functionality of bending beam load cells, mainly in eTAZ systems.

The Basics of Bending Beam Load Cells

At their core, bending beam load cells function on a easy but effective principle: transducing mechanical pressure into a measurable electrical output. Central to this method is the deformation of a beam underneath load; because the beam flexes, strain gauges—exactly attached to its surface—change electric resistance. The gauge cloth immediately affects these changes, correlating the applied force when quantified. This conversion allows the best measurement of weight.

Crucial to the efficiency of bending beam load cells is the pressure gauge itself, a issue meticulously bonded to the beam to ensure accurate pressure transduction. The dating among the applied pressure and the consequent electric sign is noticeably reliable, enabling those load cells to provide consistent and unique weight measurements throughout numerous applications.

Designed with sturdiness, bending beam load cells boast a construction which can endure the rigours of business environments. One of their standout features is their capability to offer accurate statistics notwithstanding destructive conditions. This resilience, mixed with their precision, underscores their big software in sectors demanding rigorous weight size solutions.

The Role of Bending Beam Load Cells in eTAZ Systems

In the realm of electronic visitors evaluation zones (eTAZ), bending beam load cells serve a pivotal function with the aid of allowing the suitable monitoring of automobile weights. These devices seamlessly integrate into the road infrastructure, lying in wait under the surface to capture the burden of vehicles as they pass. This records acquisition is crucial, as it feeds into systems that analyze visitors waft, vehicle kinds, and axle load distribution. Such designated tracking is instrumental for site visitors engineers, who rely upon the insights from bending beam load cell measurements to make informed choices regarding site visitors management, street protection upgrades, and techniques to alleviate congestion.Moreover, deploying bending beam load cells in eTAZ systems facilitates collecting empirical facts that can inform infrastructure development, renovation planning, and the implementation of intelligent traffic control measures.

Key Features and Specifications to Consider

Selecting the correct bending beam load cell for particular applications includes cautiously comparing several critical factors. The weight mobile’s potential is a top focus; these devices offer a wide range of load capacities, from just a few kilos to several tons. This lets in for his or her usage in packages of various scales, from sensitive weighing systems to heavy industrial equipment. Accuracy is some other paramount thing. Bending beam load cell offer one of a kind tiers of precision tailor-made to meet the exacting demands of various industries. The accuracy required will depend on the utility’s tolerance for dimension deviation.

Material creation and environmental safety are also crucial concerns. You should choose the load cellular’s fabric based on the environment in which it will operate, with options available in high-strength steel or stainless steel to withstand corrosive or extreme conditions. Environmental protection ratings, such as IP67 or IP68, imply the device’s capability to face up to dirt, water, and other environmental elements, making sure dependable operation in outdoor or harsh settings.

Lastly, the weight mobile’s signal output is critical for compatibility with tracking systems. Ensuring seamless integration and communication among structures requires matching the burden mobile’s output type with the information acquisition or tracking equipment, whether analogue or digital output is needed.

Installation and Maintenance Best Practices

Ensuring the lengthy-time period reliability and accuracy of bending beam load cells hinges on meticulous installation and regular maintenance routines. To provoke, aligning the weight cell in keeping with producer specs is critical. This step ensures that the tool effectively positions to measure forces as required. Anchoring the burden cell firmly is vital to take away capability shifts or vibrations that would skew measurements.

Maintenance is similarly essential, necessitating normal inspections for any signs and symptoms of damage or harm. Such tests help discover troubles earlier than they enhance into primary problems. Cleaning the burden mobile frequently is beneficial to prevent the build-up of substances that might intervene with its operation. Additionally, recalibration at recommended durations is paramount. Over time, slight deviations in accuracy can occur, and recalibrating the tool guarantees it keeps to provide unique measurements.

Engaging with these practices not simplest sustains the performance of bending beam load cells but also contributes to stopping operational disruptions. Attention to these info supports the enduring accuracy and functionality of the load cells, aiding in delivering reliable statistics for all packages they’re used in.

Innovative Applications of Bending Beam Load Cells in Industry

Bending beam load cells, besides their foundational function in weight measurement, ingeniously tailor across many industries for precise and revolutionary applications. In agriculture, engineers have ingeniously integrated these gadgets into the design of cattle scales, enabling precise tracking of animal weights. This functionality is crucial for effectively controlling feed and continuously assessing fitness conditions, providing a cornerstone for superior agricultural productivity. The adaptability of bending beam load cells is similarly staggering inside the healthcare region. Affected person lifts and specialized medical institution beds embed them, where accurate measurement of patient weight is crucial for clinical dosing and safe maneuvering, thus improving patient care and safety.Bending beam load cells, which ensure quality control and material handling with unmatched accuracy, benefit manufacturing approaches by their precision in automation and assembly lines.

The Future of Bending Beam Load Cells in eTAZ Systems

The evolution of bending beam load cells is about to redefine the landscape of digital site visitors evaluation zones (eTAZ), pushed via breakthroughs in clever sensor era, the Internet of Things (IoT), and superior data processing competencies. These improvements will empower bending beam load cells to deliver instant, high-precision weight facts, which is vital for dynamic site visitors tracking and management strategies. As these gadgets come to be more and more included with IoT structures, the capability to seize and transmit facts in real-time throughout networks will facilitate a more interconnected and responsive eTAZ infrastructure. This will allow real-time site visitors evaluation and the implementation of automatic structures for optimizing site visitors glide and decreasing congestion primarily based on stay load cellular records.

Integrating artificial intelligence (AI) algorithms and machine studying with bending beam load cell statistics guarantees to transform eTAZ systems into predictive equipment. These structures may be capable of forecasting site visitors styles, identifying potential bottlenecks earlier than they arise, and recommending preemptive measures to visitors controllers. Moreover, the predictive analytics derived from bending beam load cellular statistics ought to revolutionize preservation schedules and infrastructure planning by way of pinpointing areas at a higher hazard of wear and tear and tear, as a consequence prioritizing repairs and lowering the likelihood of visitors disruptions.

As those technological improvements continue to mature, the role of bending beam load cells in eTAZ systems will enlarge, paving the manner for greater green, safer, and smarter roadways. The destiny of traffic analysis and management seems promising, with bending beam load cells at the heart of innovation. They make sure the seamless glide of traffic and decorate avenue safety for all customers.

Faqs

Questions about bending beam load cells frequently contact on their applications, capability, and choice standards. Here are some common queries:

Q: How do bending beam load cells differ from different load cell?

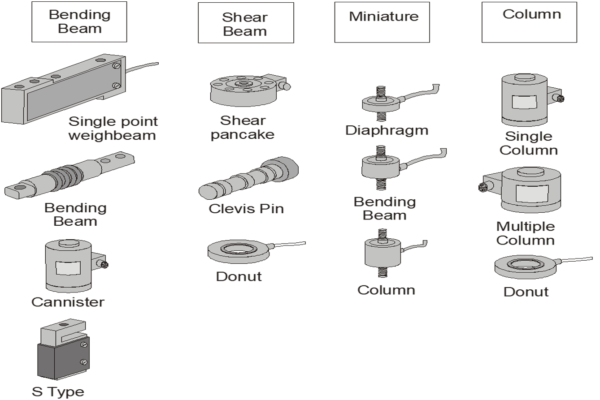

A: Bending beam load cells are wonderful of their operation thru a beam shape’s bending or flexing movement, which is at once correlated to the pressure or weight implemented. This differs from other sorts, such as compression or anxiety load cells, which measure force alongside a single axis.

Q: Can bending beam load cells be utilized in outdoor environments?

A: Bending beam load cells can be designed with substances and environmental protections like IP67 or IP68 ratings, making them suitable for outside or harsh environmental situations.

Q: How frequently ought to bending beam load cells be recalibrated?

A: Recalibration frequency depends at the usage intensity and the running situations, but undertaking it annually or bi-yearly is generally advocated to ensure persevered accuracy.

Q: What are the limitations of bending beam load cells?

A: While notably flexible, bending beam load cells will have limitations in very excessive-capability or excessive-force packages. Additionally, their accuracy might be laid low with fallacious set up or environmental factors if no longer correctly accounted for.

These FAQs goal to make clear not unusual inquiries and help in expertise the sensible concerns and applications of bending beam load cells in diverse industries.