When diving into the world of engineering and technology, you might often hear the term “torque” thrown around. Whether you’re tinkering with mechanical systems, delving into automotive engineering, or exploring electrical devices, understanding torque is key. It’s a core concept that measures rotational force and is crucial for everything from engine performance to mechanical design. This article from eTAZ Systems will help you understand what torque really means, how you use it, and answer some common questions about this essential concept.”

What Is Torque?

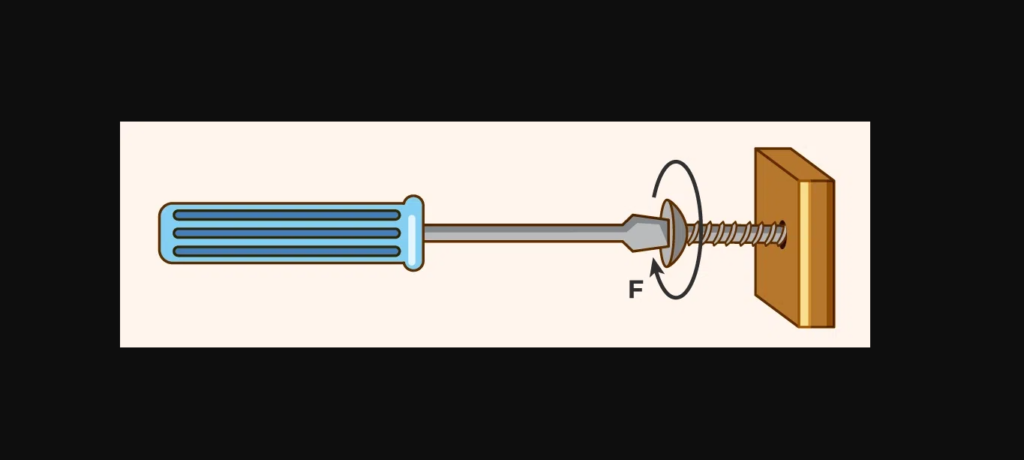

Torque, also known as “moment of force,” refers to the amount of rotational force exerted on an object around a particular axis.

. It’s what makes things spin or twist. In simple terms, you calculate torque (τ) by multiplying the force (F) you apply by the distance (r) from the axis where you apply the force. The formula looks like this:

τ=F×r\tau = F \times rτ=F×r

Here’s what the terms mean:

- τ (tau): This is the torque itself.

- F: The force applied.

- r: The distance from the axis of rotation to where the force hits.

In the SI system, we measure torque in Newton-meters (Nm), but you might also see it in foot-pounds (ft-lb) or other units depending on the context.

Types of Torque

- Static Torque: This happens when forces are applied to a stationary object. Think about balancing a see-saw or making sure a structure is stable in engineering designs.

- Dynamic Torque: This type is found in systems with rotational motion, like in automotive engines, electric motors, and other moving mechanical systems.

- Frictional Torque: Generated by friction between surfaces, this type of torque is crucial to consider in mechanical systems to avoid energy loss and ensure everything runs smoothly.

Applications of Torque

- Automotive Engineering: Torque is a key metric for vehicle performance. Higher torque means better acceleration and more effective handling of heavy loads. It’s essential for things like towing capacity and overall driving experience.

- Mechanical Engineering: Engineers use torque to design and analyze systems involving gears, levers, and shafts. Proper torque calculations ensure these components work efficiently and safely.

- Electrical Engineering: In electric motors and generators, torque affects how well the motor performs and drives mechanical loads. It’s important for motor efficiency and functionality.

- Construction and Manufacturing: Torque is vital for the proper assembly of components. “Torque wrenches help you apply the right amount of torque to bolts and nuts, ensuring that you securely fasten everything and keep it structurally sound.

How to Measure Torque

You can measure torque with various tools and methods:

- Torque Wrench: A common tool for applying and measuring torque, especially in automotive and construction tasks. It helps ensure bolts and nuts are tightened to the correct specifications.

- Torque Sensor: Used in industrial settings to measure the torque on rotating shafts or components. These sensors provide precise measurements for testing and quality control.

- Dynamometer: This measures the torque produced by engines or motors, which is useful for performance testing and research.

FAQs About Torque

Why is torque important in automotive engines?

Torque is crucial because it impacts how a vehicle performs. Higher torque improves acceleration, towing capacity, and overall driving efficiency, especially at low speeds.

How does torque differ from horsepower?

Torque measures the rotational force, while horsepower measures how quickly work is done. Horsepower is calculated from torque and engine speed (RPM). Torque shows pulling power, while horsepower reflects overall performance and speed.

Can you adjust torque in mechanical systems?

Yes, many mechanical systems allow for torque adjustments. In cars, for instance, components like clutches can be adjusted. In manufacturing, rotational force regulation systems assist in enhancing efficiency.

What role does torque play in electrical motors?

Torque in electrical motors affects their ability to drive loads. It impacts efficiency, speed, and performance. Proper torque management is crucial for the motor to work effectively.

How does friction affect torque measurement?

Friction can create resistance and influence the precision of torque measurement.

It’s important to account for frictional forces and calibrate tools correctly for precise measurements.

What is torque’s significance in construction and manufacturing?

Accurate torque application is key in construction and manufacturing for proper assembly and fastening of components. It helps maintain structural integrity and ensures the reliability of products.

Conclusion

Torque is a fundamental concept in engineering and technology, influencing everything from automotive performance to mechanical design and electrical applications. By understanding and measuring torque, engineers and technicians can enhance system functionality and performance.

For more insights on torque and other engineering concepts, eTAZ Systems is here to help. If you have any questions or need expert assistance, don’t hesitate to reach out to our team.