Load cells are essential components in eTAZ systems, supplying correct weight measurements that are essential for diverse packages. However, like any other piece of equipment, load cells can enjoy put on and tear through the years, affecting their performance. Knowing how to check a load cell is vital for retaining the accuracy and reliability of your machine. In this blog publish, we can demystify the system of checking a load cellular, supplying you with the knowledge and tools necessary to make sure your load cellular is functioning optimally.

Understanding Load Cells and Their Importance in eTAZ Systems

Load cells are important in translating physical force into a quantifiable electrical output, making them the backbone of precise weight dimension in eTAZ structures. These structures depend closely at the accuracy of load cells for quite a few programs, from the calibration of weighing scales to the tracking and manage of business procedures, or even in the suitable measurements required in aerospace engineering. The functionality of eTAZ systems is deeply intertwined with the reliability of these load cells, as they offer the important data to make certain operations run easily and thoroughly. An improperly functioning load cell can cause misguided information, which in critical structures could bring about safety risks or widespread monetary losses due to errors in processing or production. Hence, the role of load cells extends past mere weight dimension; they may be essential in retaining the integrity and efficiency of eTAZ structures.

Preparing to Check Your Load Cell: What You Need to Know

Before diving into the diagnostic method of your load cellular, assembling the right toolkit and documentation is vital. Ensure you have got the burden cellular’s manufacturer specs reachable, as these documents offer invaluable steerage on predicted overall performance benchmarks and trying out parameters. Equally vital are any previous calibration records, that can offer insights into the load mobile’s performance history and spotlight ability traits or problems that may have arisen over the years. The setup for testing should additionally encompass obtaining the necessary trying out device, together with a multimeter or an oscilloscope, that are crucial for undertaking thorough electrical reviews. Additionally, safety precautions cannot be overstated; ensure the weight cell is disconnected from any electrical energy resources to mitigate threat, and affirm that the complete device is well grounded.

Visual Inspection: The First Step in Checking Load Cells

Initiating the technique of comparing a load mobile starts offevolved with a meticulous visible inspection. This crucial step calls for a eager eye to spot any physical abnormalities that would trace at underlying troubles. Inspect the burden cell and its instantaneous connections for visible symptoms of damage along with deformities, cracks, or symptoms of corrosion, that could compromise its capability. Equally, scrutinize the wiring and connections for any warning signs of damage, such as fraying or loosening, which would possibly hinder the burden mobile’s performance. This stage is critical for early detection of ability issues that might affect the accuracy and reliability of weight measurements in eTAZ systems. Identifying those problems early on can shop time and sources by stopping extra large issues down the line.

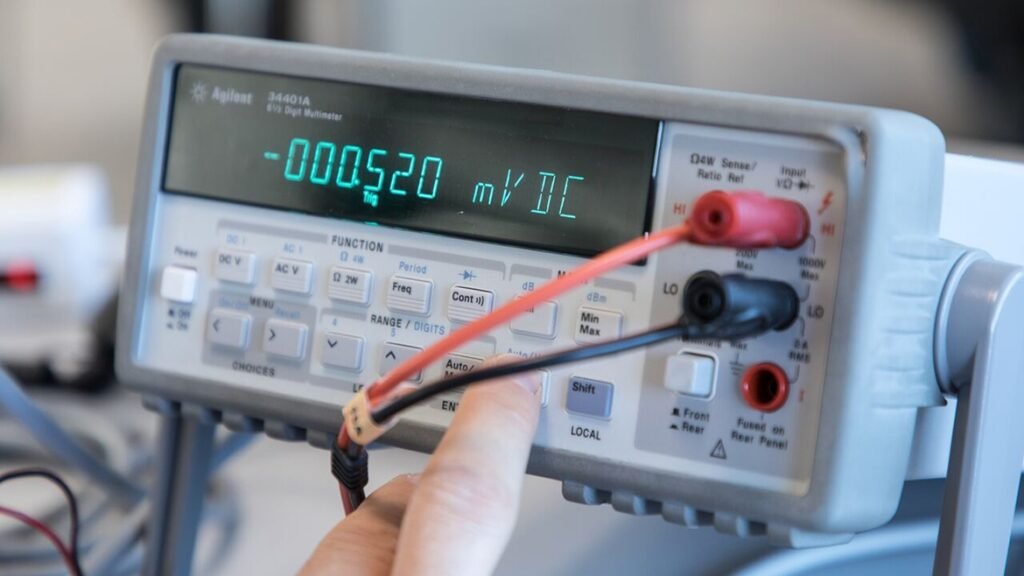

Electrical Testing: Identifying Hidden Problems

Electrical testing plays a pivotal function in uncovering troubles that are not straight away seen to the naked eye. This section entails deploying equipment inclusive of a multimeter or an oscilloscope to scrutinize the burden cellular’s output sign, ensuring it aligns with the specified parameters set through the producer. Additionally, this step encompasses a radical exam of the burden cell’s resistance tiers. Anomalies in resistance or unexpected signal outputs may be indicative of underlying problems that won’t be obvious in the course of a visible inspection. These electric reviews are essential; they spotlight discrepancies that could compromise the efficacy and accuracy of weight measurements in eTAZ systems. Identifying such variances early allows for well timed interventions, assisting to preserve the load cell’s reliability and overall performance.

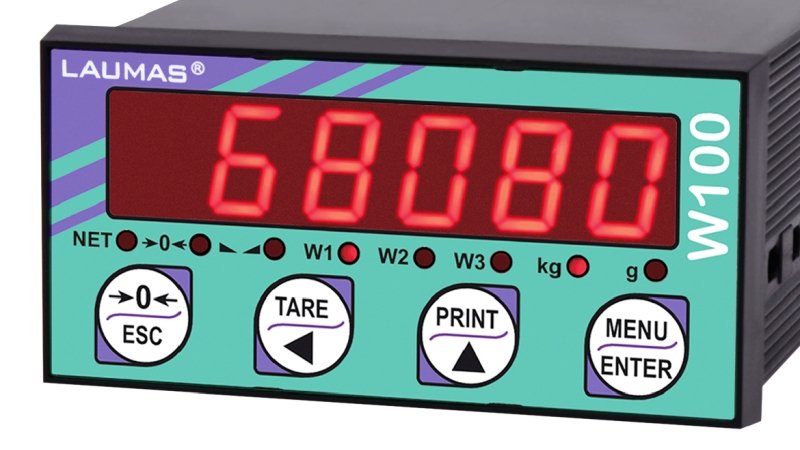

Mechanical Testing: Ensuring Load Cell Integrity

Mechanical checking out is a essential thing of the general evaluation of a load cell. This manner entails the utility of a known force or weight to the burden cell and staring at the ensuing output to verify its accuracy. This step is instrumental in making sure that the weight cellular responds successfully under actual operating situations. Disparities among the regarded force carried out and the load mobile’s output sign can sign capacity troubles, necessitating further investigation and viable recalibration or restore. This testing phase is vital for confirming that the how to Check a Load Cell isn’t simplest accurate however additionally reliably constant in its performance. Effective mechanical trying out affords reassurance that the load mobile can be depended on in its position within eTAZ systems, assisting the accuracy of essential weight measurements.

Calibration: The Key to Accurate Load Cell Readings

Calibration stands because the cornerstone of ensuring your how to Check a Load Cell supplies particular readings. It’s a procedure that quality-tunes the burden cellular, adjusting it to suit reference requirements and correcting any drifts in accuracy through the years. This is not simply a advice however a need, specifically following repairs, significant adjustments inside the running environment, or when the load cellular is part of a device in which precision is paramount. Engaging in everyday calibration classes facilitates in identifying even the slightest deviations in measurement, which would possibly in any other case compromise the great of facts and the performance of the eTAZ structures. During calibration, professionals rent certified weights and superior device to benchmark and alter the weight cellular’s overall performance. This rigorous process guarantees that the weight cell continues to characteristic within its precise accuracy variety

When to Seek Professional Help: Troubleshooting Complex Issues

Navigating the intricate details of a load cellular’s overall performance troubles can now and again exceed the understanding to be had in-residence. Complex problems that persist notwithstanding thorough visual, electric, and mechanical checking out may require the perception of a professional. Experts within the discipline possess a deep knowledge of how to Check a Load Cell era, permitting them to perceive and rectify issues that are not right now obvious. They come ready with specialized diagnostic equipment and feature get admission to to resources that might not be effortlessly available in any other case. Consulting with those specialists can prevent minor issues from escalating into fundamental screw ups, making sure the seamless operation of your eTAZ device. Their capacity to provide focused upkeep or modifications can shop vast time and sources in the long run.

Maintaining Your Load Cell: Tips for Longevity

Ensuring the sturdiness and ongoing accuracy of your load mobile includes a commitment to recurring maintenance practices. Regular cleansing is paramount; dust and debris can intrude with mechanical components and affect performance. Also, steady inspections are essential for early detection of ability issues, making an allowance for timely interventions before they expand into greater giant issues. Calibration is any other vital detail of protection, aligning the burden mobile’s output with general references and correcting deviations that could occur over time. Furthermore, it is essential to adhere to the weight mobile’s precise weight limits to save you stress and damage due to overloading. Implementing those practices now not best complements the operational lifespan of your how to Check a Load Cell but additionally ensures it maintains to supply reliable and correct measurements, supporting the powerful functioning of your eTAZ gadget.

FAQS

FAQs on Checking Load Cells in eTAZ Systems:

Q1: How regularly need to I take a look at my load cell for ideal performance?

A: It is usually recommended to carry out a habitual take a look at at least as soon as a yr or after any event that could doubtlessly impact its overall performance, along with an electrical surge, bodily impact, or significant environmental adjustments.

Q2: Can I use any multimeter for electric trying out on a load cell?

“Yes, you can use most multimeters with the functionality to measure resistance and voltage for fundamental electric testing. However, you may need precise features or superior multimeters for more detailed diagnostics.”

Q3: What is the significance of resistance tiers throughout load mobile testing?

A: Resistance degrees offer insight into the health of the burden cellular’s stress gauges and wiring. Deviations from expected resistance values can suggest capacity troubles such as damaged pressure gauges or compromised connections.

Q4: Is recalibration vital after repairing a load mobile?

A: Yes, recalibration is important after any restore or substantial maintenance work on a load cell to make sure it returns to imparting correct and reliable measurements.

Q5: What need to I do if my load cell fails mechanical testing?

A: If your load mobile fails mechanical checking out, it could need recalibration, repair, or in some instances, replacement.Visit a professional to determine the quality course of motion based on the specific problems identified.