If you figure with load cells, eTAZ systems you understand how important it’s far to make sure they’re functioning efficaciously. One key element of load mobile overall performance is its resistance. In this comprehensive manual, we will stroll you via how to check load mobile resistance to make sure most useful functionality.

Understanding Load Cell Resistance and Its Importance

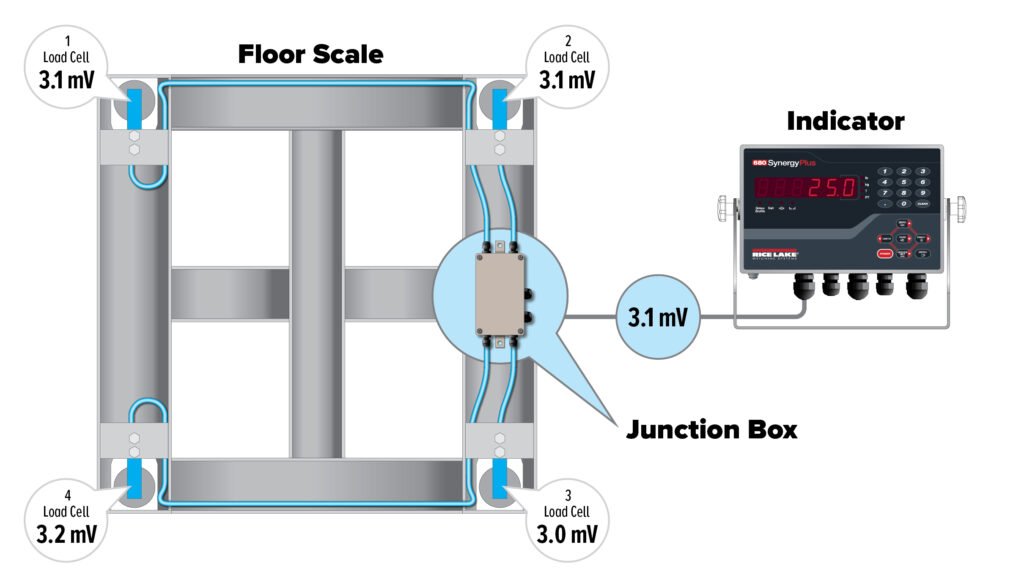

The resistance of a load cell plays a pivotal role within the precision and reliability of its dimension talents. This electrical resistance, which acts as a barrier to the modern-day inside the load cellular circuitry, can appreciably effect the device’s operational performance. Variations in resistance, added on by way of external factors consisting of temperature fluctuations, moisture degrees, and bodily strain, can skew the accuracy of weight measurements. Consequently, maintaining a keen eye on this parameter is essential for preserving the integrity of the load mobile’s output.

The sensitivity of a load cell, or its ability to provide a sign in reaction to a weight alternate, is intimately tied to its resistance. Small deviations from an appropriate resistance values can cause widespread errors inside the load cell’s readings. This sensitivity to adjustments underscores the need of frequently tracking load cell resistance, to preemptively become aware of and rectify any anomalies that could affect moreover measurement precision.

Moreover, expertise the connection among a load cell’s resistance and its environmental and operational situations permits customers to implement proactive measures. By controlling these factors, one could mitigate their impact at the load mobile’s resistance and, by way of extension, its ordinary overall performance. Recognizing the essential role that resistance plays no longer only illuminates the significance of regular exams but additionally the need for an intensive hold close of the way one-of-a-kind load mobile types react to varying situations.

The Types of Load Cells and Their Resistance Characteristics

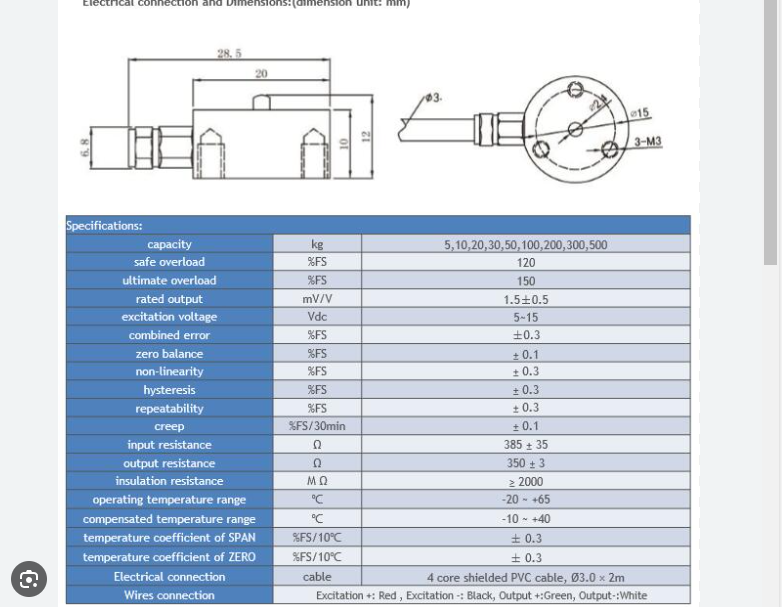

Load cells are available various forms, each prominent by way of unique resistance properties that dictate their performance beneath one of a kind situations. The stress gauge load mobile, famous for its versatility and precision, uses metal foil stress gauges that change resistance as weight is applied, making them sensitive to moderate changes in load. Their design lets in for high resistance to environmental influences together with temperature and humidity, which contributes to their great use in commercial and business weighing systems.

Hydraulic load cells, alternatively, function based at the principle of fluid displacement below pressure, a manner that does not inherently depend on electric resistance adjustments for weight measurement. However, the resistance in the electrical circuitry used to screen the hydraulic strain can be illustrate critical in ensuring accurate readings.

These cells withstand external conditions much better and are frequently used in harsh environments.

Pneumatic load cells utilize air stress to determine weight and, much like hydraulic cells, measure weight with out direct reliance on modifications in electrical resistance. Nonetheless, the components worried inside the transduction of strain to an electrical signal may additionally have particular resistance characteristics that need to be monitored for accurate functionality.

Understanding these resistance characteristics is important for deciding on the right load mobile for a particular utility and for troubleshooting any capacity issues which can stand up for the duration of their operation. Each kind’s precise response to environmental situations and moreover cargo modifications underscores the importance of thinking about resistance as a aspect in load cell choice and renovation.

Tools and Equipment Needed for Resistance Checki

Gathering the proper set of gear and device is a pivotal first step in successfully checking the resistance of a load cell. Essential to this manner is a dependable multimeter, which serves as the cornerstone for acquiring accurate resistance measurements. Calibrate the multimeter properly and set it to the correct resistance measurement mode before use. Additionally, use calibration weights to apply a known force to the weight cell, allowing for the accurate determination of the correlation between weight and resistance. A stable power supply is another key factor, ensuring that the weight cell and any related electronics are operating underneath consistent conditions for the duration of the trying out section. For the ones aiming to music and examine resistance measurements over time, a computer ready with specialized facts logging software program can be a useful device.

Step-through-Step Guide to Checking Load Cell Resistance

Begin via ensuring the load mobile is completely disconnected from its energy supply to save you any electrical risks. Next, steady a connection between the multimeter’s leads and the weight cell’s terminals. It’s critical that this connection is solid and loose from any interference. Once connected, alter your multimeter to measure resistance.

Now, you are ready to use a acknowledged pressure or weight onto the burden cellular. To set up a baseline against which to evaluate the resistance measurement, take this vital step. Carefully study the multimeter’s reading as you apply the weight, noting the displayed resistance value.

It’s at this juncture that the recorded resistance wishes to be scrutinized towards the equally producer’s specified resistance range for the load cell. Any sizable deviation from this variety should imply an underlying trouble with the burden cellular’s capability.

Should the resistance fall within the anticipated range, the load cell is in all likelihood working correctly. “However, if the measured resistance deviates outside of this range, you may need to conduct similar research or seek expert evaluation to pinpoint and rectify the trouble.”

Throughout this manner, it’s imperative to handle the load cellular and trying out system with care to make certain accurate readings and to save you any ability harm to the components worried.

Common Issues and Troubleshooting Tips

During the procedure of checking load cellular resistance, you might encounter numerous demanding situations. One problem could be encountering an erratic or fluctuating resistance analyzing, which often points to a problem with the connections. Ensure that each one connections among the multimeter and the burden mobile are steady and intact. Also, investigate the multimeter’s leads for any signs of damage or harm, illustrate as compromised equipment can lead to misguided readings.

Another commonplace trouble is a resistance dimension that does not align with the producer’s distinctive range. This discrepancy should suggest that the load mobile needs calibration or, in some cases, replacement. Qualified employees should perform the calibration to ensure the accuracy and reliability of the load cell.

Additionally, incorrect mounting or excessive pressure on the load cell can influence the resistance readings. Ensure you hook up the weight cell successfully according to the producer’s commands and avoid subjecting it to undue stress, as this can affect the resistance and cause long-term damage to the tool.

By addressing these common troubles directly and following the manufacturer’s renovation recommendations, you can help ensure the continued accuracy and sturdiness of your load mobile device.

How to Maintain Load Cell Resistance for Optimal Performance

Maintaining the greatest resistance of a load mobile is essential for making sure accurate and dependable measurements. To acquire this, a proactive technique closer to renovation is necessary. Periodically test for any physical damages consisting of cracks or deformations, as these can impact the resistance and capability of the weight cell. Regular cleansing to put off dirt and debris will even save you capability issues related to poor conductivity and resistance adjustments. It’s crucial to screen the burden mobile’s surroundings, controlling factors which includes temperature and humidity that can have an effect on its resistance. Additionally, keep away from exposing the weight cellular to conditions that exceed its rated capability, as overloading can completely regulate its resistance characteristics and result in faulty readings. Implementing these preservation practices will help keep the burden mobile’s resistance within its designated range, secondly contributing to the sturdiness and dependability of the weighing gadget.

FAQS

Q: How often is it important to assess the resistance of a load mobile?

A: Regular monitoring of load mobile resistance is pivotal for keeping its accuracy and reliability. Ideally, you should perform a radical check yearly or if there are warning signs of performance degradation. Consistent exams assist in early identification of potential issues, taking into account timely interventions.

Q: Is it viable to modify the resistance readings of a load mobile?

A: Adjusting the resistance readings of a load cellular immediately is not usually possible as those readings are intrinsic to the load cell’s layout and operation. However, calibration is a process that can make certain the weight cellular’s output remains correct and within certain tolerances. Always carry out calibration in accordance with the manufacturer’s specs and, if necessary, use expert services to guarantee precision.

Q: What movements have to be taken if the resistance of a load cell falls outdoor the encouraged variety?

A: If the resistance readings deviate from the manufacturer’s advocated variety, it’s vital to first verify the integrity of all connections and the situation of the load cell itself for any physical damage. Should these checks no longer solve the difficulty, professional recalibration or, in a few cases, Similarly substitute of the weight mobile is probably necessary to restore right characteristic.

Q: Can environmental situations affect load cellular resistance, and how can this be mitigated?

A: Yes, environmental factors including temperature and humidity can effect the resistance of a load mobile. To mitigate these results, ensure that you use the load cell within its specific environmental conditions and implement environmental controls where feasible. Regular upkeep and tests also play a crucial position in identifying and compensating for any resistance changes because of environmental factors.