The stress gauge load cellular sensor is a important thing inside the global of eTAZ systems structures, presenting correct measurements which might be vital for various packages. These sensors play a essential position in ensuring the efficiency and reliability of electronic systems, making them crucial in industries starting from manufacturing to healthcare. In this weblog post, we can delve into the fundamentals of strain gauge load cellular sensors, their vital position in eTAZ systems, the advantages of using them in one-of-a-kind industries, how to pick out the proper sensor in your utility, the brand new improvements and future developments in sensor technology, actual-world programs, and fulfillment tales of eTAZ structures.

Understanding the Basics of Strain Gauge Load Cell Sensors

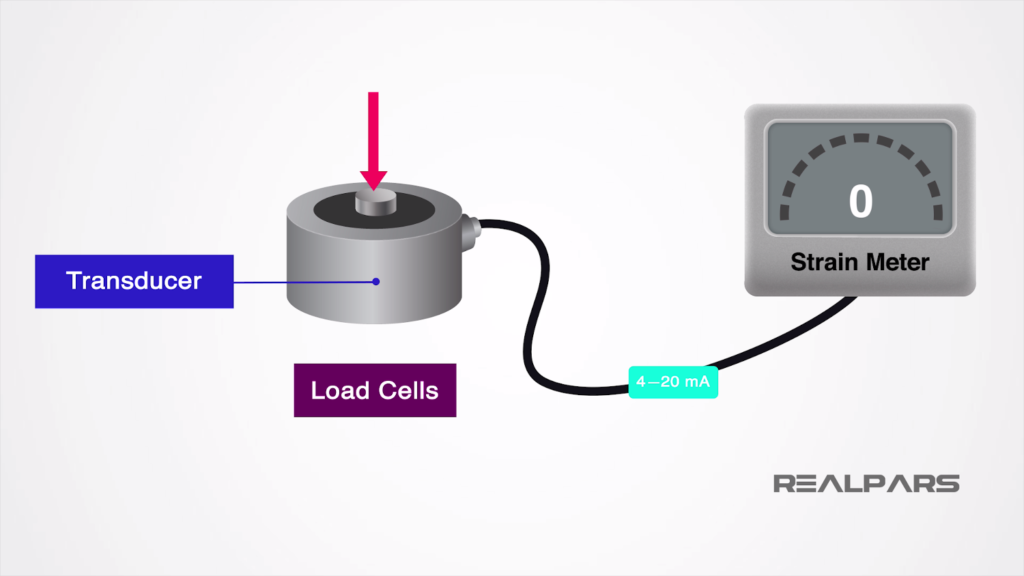

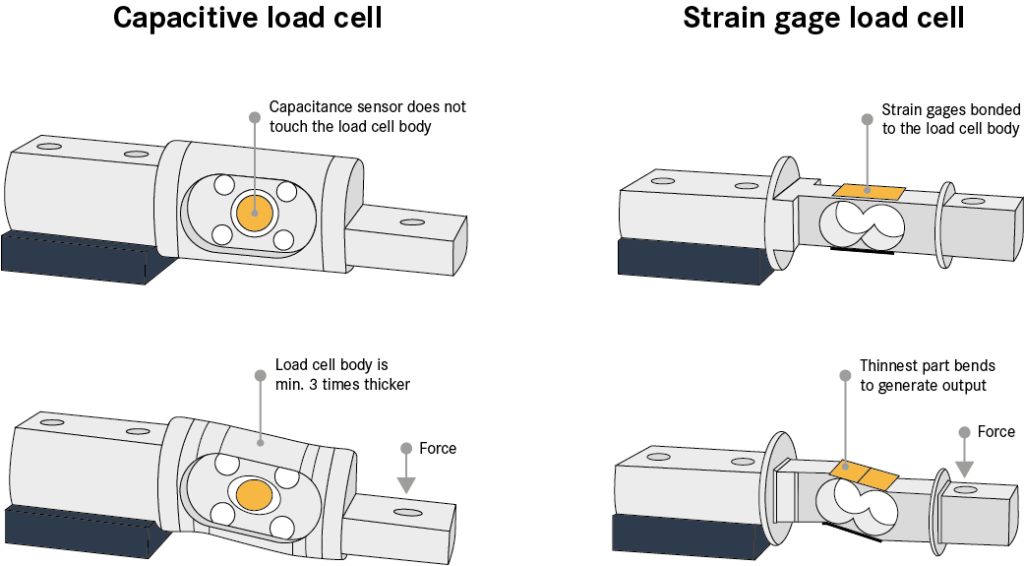

At the center of a pressure gauge load mobile sensor lies a completely unique mechanism that translates mechanical pressure into a quantifiable electrical output. Using a strain gauge, crafted from either exceptional wire or a metallic foil pattern, achieves this by showcasing changes in electric resistance when stretched or compressed. The precept hinges on the strain gauge’s sensitivity to deformation: as the attached cloth flexes underneath pressure, the gauge’s resistance varies proportionally. Using a strain gauge, crafted from either exceptional wire or a metallic foil pattern, achieves this by showcasing changes in electric resistance when stretched or compressed.

This conversion manner is what permits for the right quantification of a big selection of bodily forces consisting of weight, strain, torque, and extra. To make sure the accuracy and reliability of those measurements, the stress gauge is meticulously bonded onto a backing this is each bendy and sturdy, capable of withstanding the precise forces it’ll degree. This cautious alignment and bonding are vital, as they directly have an impact on the sensor’s overall performance and durability. The interaction among the pressure gauge and its backing under applied forces is what permits the load cellular sensor to offer reliable and precise statistics throughout numerous applications, forming the muse upon which eTAZ systems perform.

The Integral Role of Strain Gauge Sensors in eTAZ Systems

In eTAZ systems structures, stress gauge load cellular sensors are crucial, performing because the primary supply of crucial records for measuring torque, perspective, and pressure with unheard of precision. These structures, vital to a myriad of sectors, depend upon the accurate and regular readings provided by the sensors to make certain most fulfilling overall performance. For example, in business automation, the capacity to precisely display and regulate machinery in actual-time is essential to maintaining excessive manufacturing standards and performance. Similarly, inside the realm of scientific era, the precise measurements presented by means of these sensors are important for devices that require utmost precision for patient safety and care, consisting of surgical robots and diagnostic equipment. Beyond their software in making sure product satisfactory and safety, the facts from pressure gauge load mobile sensors empower eTAZ structures to innovate and refine methods, contributing to advancements in technology and engineering.

Benefits of Using Strain Gauge Load Cell Sensors in Various Industries

The adoption of pressure gauge load cell sensors transcends a wide array of enterprise verticals, providing a large number of blessings that streamline operations and enhance product and service exceptional. Within the producing region, the precision and control afforded by means of these sensors without delay translate into superior product consistency, lowering waste and augmenting production efficiency. In the area of healthcare, the deployment of those sensors in important clinical devices facilitates correct dosage delivery and crucial signal tracking, for that reason raising affected person care standards. Automotive and aerospace sectors gain extensively as properly, where the rigorous demands for safety and overall performance necessitate the reliability and precision these sensors provide at some point of checking out and validation phases.

How to Choose the Right Strain Gauge Load Cell Sensor for Your Application

Selecting the appropriate pressure gauge load cellular sensor for a selected utility entails a nuanced knowledge of both the operational needs and the particular traits of the sensor itself. Critical elements inclusive of the nature and value of the pressure to be measured must first be considered. For programs requiring pleasant precision, like the ones inside the medical discipline or advanced production, sensors with a high diploma of accuracy and minimum drift over the years are paramount. Additionally, the environmental conditions in which the sensor will function can not be ignored. For environments uncovered to moisture, dirt, intense temperatures, or corrosive materials, selecting a sensor with suitable protecting measures or coatings is important to ensure its longevity and reliability.

Equally crucial is understanding the dimension variety required for the software. A sensor’s capacity to accurately degree inside the desired variety without sacrificing decision is essential for imparting precious facts. The bodily length and installation constraints of the software region may additionally dictate the selection of sensor, mainly in compact or difficult setups.

Finally, thinking about the sensor’s compatibility with current structures for ease of integration, as well as its cost-effectiveness within the venture’s finances, will resource in making a well-rounded decision. Engaging with specialists or suppliers who can offer insights into the most suitable sensor alternatives based totally on those criteria will facilitate an knowledgeable preference, making sure that the chosen pressure gauge load cellular sensor meets the application’s unique needs successfully.

Innovations and Future Trends in Strain Gauge Load Cell Sensor Technology

The frontier of strain gauge load cell sensor era is unexpectedly increasing, driven through the relentless pursuit of more desirable overall performance and adaptability throughout various sectors. Emerging traits spotlight a shift in the direction of the mixing of IoT talents, permitting sensors to communicate seamlessly with cloud-based totally systems for real-time records evaluation and choice-making. The increase in connectivity will revolutionize predictive protection and operational performance by providing actionable insights before potential device failures occur. Additionally, the development of ultra-thin and flexible pressure gauges is opening new avenues for applications in wearable technology and soft robotics, where conformability and minimal interference with natural movements are crucial. These advanced sensors, capable of capturing minute changes with excellent accuracy, are poised to expand the scope of monitoring and interaction within human-centric environments.

Real-World Applications and Success Stories of eTAZ Systems

The effect of eTAZ structures, powered via strain gauge load mobile sensors, is evident throughout more than one sectors, illustrating their versatility and effectiveness. In the automotive enterprise, these structures had been instrumental in crash take a look at simulations, where specific force measurements can mean the distinction among existence and death, main to cars designed with superior protection requirements. Aerospace organizations leverage eTAZ structures to reveal the structural integrity of aircraft, making sure they face up to the rigors of flight and excessive conditions, as a consequence safeguarding passenger safety and optimizing performance. In the scientific field, eTAZ structures have facilitated breakthroughs in surgical gadget, permitting tools that perform with extraordinary precision, enhancing surgical results and patient recovery instances. Robotics, too, has visible a transformation,