Load cells are essential components in a wide range of programs in which weight dimension is essential. Whether utilized in industrial scales, material testing machines, or medical gadgets, the accuracy of load cells is paramount. Proper calibration ensures that these gadgets provide unique and reliable facts. In this complete manual, we, at eTAZ Systems, will stroll you thru the step-by way of-step manner of calibrating a load cellular.

Understanding Load Cells

How to Calibrate a Load Cell?

Before diving into the calibration system, it’s important to apprehend what a load cellular is and the way it works. A load cell is a transducer that converts force into an electrical sign. This conversion is completed thru the deformation of stress gauges, which can be bonded to a cloth that deforms beneath load. The deformation of the stress gauges causes a change in electric resistance, which can be measured and converted right into a weight studying.

Types of Load Cells

Strain Gauge Load Cells: The maximum commonplace type, these load cells use pressure gauges to measure deformation.

Hydraulic Load Cells: Utilize a fluid-filled chamber to degree weight.

Pneumatic Load Cells: Operate using air strain to determine weight.

Capacitive Load Cells: Measure modifications in capacitance because of deformation.

Importance of Calibration

Calibration is the technique of configuring a load mobile to offer accurate measurements inside a designated variety. Over time and through usage, load cells can float due to factors like mechanical put on, temperature adjustments, and electrical interference. Regular calibration ensures that the burden mobile maintains its accuracy and reliability.

Tools and Equipment Needed

How to Calibrate a Load Cell, To calibrate a load mobile, you may want the subsequent equipment and equipment:

Calibration weights: Known weights which are traceable to country wide or worldwide standards.

Calibration platform: A solid and level platform wherein the load mobile and weights can be located.

Load mobile indicator or readout: A tool that shows the output from the burden mobile.

Multimeter: For measuring electric outputs and ensuring right connections.

Screwdrivers and wrenches: For making mechanical changes.

Step-through-Step Calibration Process

Step 1: Preparation

How to Calibrate a Load Cell? Select a Stable Environment: Ensure that the calibration place is unfastened from vibrations, temperature fluctuations, and drafts. These factors can affect the accuracy of the calibration method.

Warm-Up the Load Cell: Turn at the load cell and allow it heat up for at least 15-30 minutes. This guarantees that the weight cellular is working at a strong temperature.

Check Zero Balance: With no load implemented, the weight cellular have to study 0. If it does now not, adjust the 0 setting at the indicator.

Step 2: Apply Calibration Weights

Initial Zero Setting: Confirm that the burden cellular reads 0 with none load.

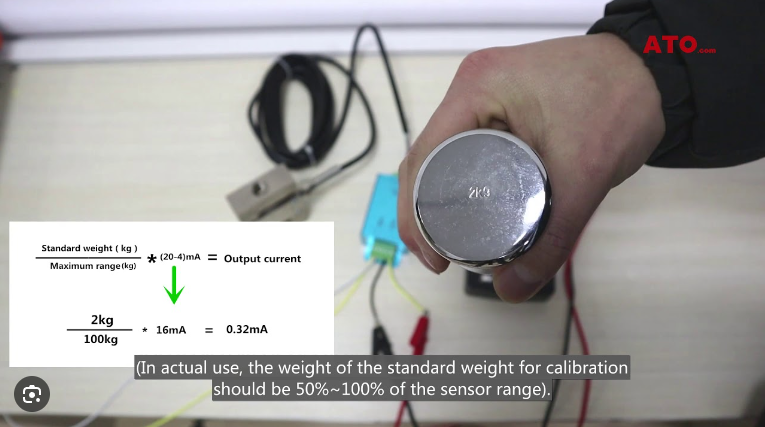

Apply Known Weights: Place a recognized calibration weight at the load cell. Record the reading from the load cell indicator.

Incremental Loading: Continue to feature recognised weights incrementally and record the corresponding readings from the load cellular indicator.

Full Scale Verification: Apply weights as much as the maximum ability of the burden cell to make certain it reads appropriately at all factors within its range.

Step 3: Data Recording and Analysis

Record Data: Create a desk to file the implemented weight and the corresponding reading from the burden cell.

Calculate Error: Determine the difference among the implemented weight and the weight cell analyzing. This distinction is the calibration error.

Plot Calibration Curve: Plot the applied weight versus the burden mobile studying to visualize the calibration curve. The best calibration curve is a straight line indicating a linear courting between carried out weight and load mobile output.

Step four: Adjust Load Cell Output

Adjust Gain and Offset: Based on the calibration curve, alter the advantage and offset settings on the load cell indicator to reduce the calibration mistakes.

Repeat Calibration Steps: Repeat the software of calibration weights and recording of readings to affirm that changes have stepped forward accuracy.

Fine-Tune Settings: Continue to excellent-music the advantage and offset settings until the burden cell readings closely suit the implemented weights.

Step five: Verification and Documentation

Final Verification: After changes, perform a very last verification by using making use of various weights and making sure that the burden mobile readings are inside suitable mistakes limits.

Documentation: Document the calibration system, together with the environmental conditions, equipment used, calibration weights, and final calibration effects. Maintain this documentation for destiny reference and great manage.

Calibration Best Practices

To ensure correct and dependable calibration, follow these first-class practices:

Use Traceable Weights: Always use calibration weights that are traceable to national or global requirements.

Regular Calibration: Calibrate load cells regularly, especially if they’re used in essential packages. The frequency of calibration relies upon at the application, usage, and manufacturer recommendations.

Environmental Control: Perform calibration in a managed environment to reduce outside factors that could affect accuracy.

Proper Handling: Handle load cells and calibration weights with care to keep away from harm or contamination that could affect readings.

Professional Calibration Services: For excessive-precision packages, consider the use of professional calibration offerings to make certain the very best stage of accuracy.

Troubleshooting Common Calibration Issues

Inconsistent Readings

Cause: Environmental elements, mechanical put on, or electric interference.

Solution: Ensure a solid surroundings, take a look at for mechanical troubles, and affirm electric connections.

Non-Linear Output

Cause: Strain gauge troubles, mistaken mounting, or incorrect calibration weights.

Solution: Inspect the stress gauges, ensure right mounting, and verify the accuracy of calibration weights.

Zero Drift

Cause: Temperature modifications, mechanical shifts, or electric instability.

Solution: Allow the weight cell to stabilize, take a look at for mechanical shifts, and make certain strong electricity deliver.

Conclusion

How to Calibrate a Load Cell? Calibrating a load cellular is a critical method that guarantees correct and reliable weight measurements. By following the step-through-step manual supplied with the aid of eTAZ Systems, you could calibrate your load cells efficiently, preserving their accuracy and lengthening their lifespan. Remember to carry out normal calibration, deal with system with care, and file the calibration procedure meticulously. For programs requiring the highest level of precision, recollect expert calibration services. With these practices, you could make sure that your load cells carry out optimally, offering correct records on your packages.

At eTAZ Systems, we’re committed to presenting top-satisfactory dimension solutions and support. For more records on load cell calibration or to explore our range of load cellular merchandise, go to our internet site or touch our expert team.