Load cell calibration is important to ensuring the accuracy and reliability of load cellular measurements. You can be assured that your device provides specific and steady information by calibrating load cells. Additionally In this weblog publish, we can delve into the importance of load cell calibration, the position of eTAZ systems on this process, forms of load cellular calibration device, a step-via-step manual to calibrating load cells, commonplace challenges in calibration and how to conquer them, and the future of load cell calibration technology.

Understanding Load Cell Calibration

Load mobile calibration is a meticulous method designed to make certain a load mobile’s output is specific and reliable. This technique involves aligning and verifying the burden cellular’s output by evaluating it in opposition to mounted weights or forces. The necessity for calibration arises from the capacity for load cells to deviate from their correct size paths due to various factors, which include environmental impacts, mechanical stress, and regular wear and tear. Disc discrepancies may be recognized through subjecting load cells to calibration, Moreover and adjustments may be made accordingly. This not handiest secures the accuracy of measurements but additionally safeguards in opposition to the consequences of size errors, which could bring about full-size financial losses or compromises in safety. Calibration is accordingly foundational to keeping the size integrity of load cells across a big range of programs, from business weighing systems to precision testing gadget.

The Role of eTAZ Systems in Load Cell Calibration

TAZ systems have emerged as critical equipment in load cell calibration, drastically enhancing the precision and performance of this vital system. These sophisticated systems contain modern era and software program that automate many elements of calibration, Furthermore decreasing the capability for human error and growing the accuracy of measurements. With abilities which includes computerized statistics logging, eTAZ systems capture comprehensive records of every calibration consultation, facilitating traceability and compliance with first-class standards.

An critical characteristic of eTAZ structures is their potential to offer real-time remarks at some stage in the calibration process. This instant insight permits technicians to make on-the-spot changes, making sure the weight cellular’s performance meets the required specs before the technique concludes. In addition, eTAZ structures’ adaptability manner they may be tailor-made to a extensive variety of load cell types and calibration scenarios, making them flexible gear in each laboratory and area settings.

Integrating eTAZ structures into load mobile calibration workflows represents a big breakthrough in measurement generation. By streamlining the calibration system, those structures not most effective shop time but additionally enhance the reliability of the calibrated load cells, contributing to the overall integrity of measuring and tracking applications in various industries.

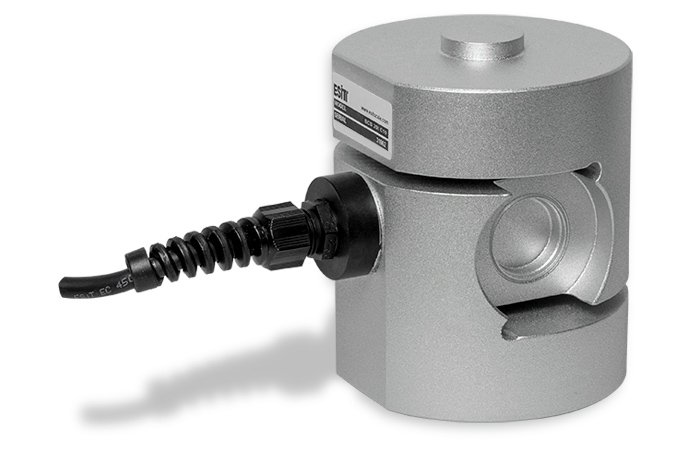

Types of Load Cell Calibration Equipment

The panorama of load mobile calibration device is numerous, catering to a large spectrum of requirements based at the precision needs and the character of the weight cellular itself. The array of equipment at one’s disposal spans from the essential to the highly sophisticated. Among these, load cell simulators stand out for his or her potential to imitate electric indicators equal to bodily hundreds. They provide a streamlined and efficient calibration method with out actual mass software. Force gauges are some other pivotal kind, extensively used for his also or her portability and simplicity of use, providing direct pressure application and dimension skills which might be vital for onsite calibration responsibilities.

In software program, calibration applications have revolutionized the process, supplying extraordinary precision and manage. These applications facilitate complicated analysis, automate calibration procedures, and make certain that statistics logging and report-maintaining are seamless and comprehensive. For physical calibration needs, calibration stands are helpful, presenting the mechanical structure important to use precise forces or weights to the weight cell in a managed way. This gadget, whether used for my part or in combination, guarantees that the calibration technique may be tailor-made to meet the precise requirements of the load cell, thereby making sure the very best ranges of accuracy and reliability in measurements.

Step-via-Step Guide to Calibrating Load Cells

Embarking at the calibration of load cells entails a meticulous approach to make certain that the final results is specific and reliable. Here’s a structured manual to navigating via this crucial method:

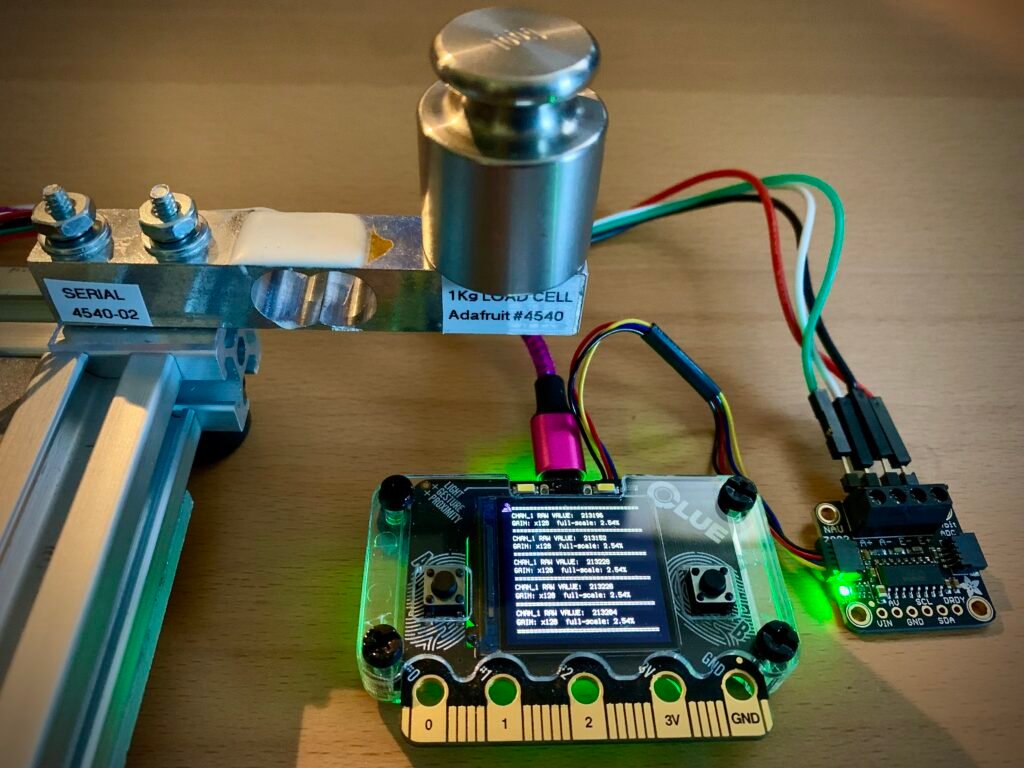

**Initialization**: Set up the load cellular and any related calibration system. Ensure that all additives are correctly related and that the weight cellular is correctly installed to avoid measurement mistakes due to setup problems.

**Zeroing Out**: Conduct a 0 balance calibration to set up a baseline dimension.

Make sure to account for any inherent electrical noise or offset earlier than utilizing any loads.

**Load Application**: Gradually practice known loads or forces to the weight cell, adhering to the endorsed increment steps.

The load cellular guarantees that it correctly captures the response to various hundreds.

**Data Acquisition**: Carefully report the weight cell’s output for every carried out load. This records is crucial for reading the burden cell’s performance and accuracy underneath special conditions.

**Adjustments**: Based on the facts collected, become aware of any discrepancies and alter the load cell’s output. This may also involve tweaking the load cell’s configuration or recalibrating the gadget.

**Validation**: To affirm the calibration’s validity, mirror the mortgage application technique. This step is essential for verifying that the changes have performed the preferred accuracy stages.

By leveraging eras such as eTAZ structures throughout this process, it can simplify and enhance the precision of each step, thereby ensuring that the calibration procedure adheres to the highest standards of accuracy and efficiency.

Pingback: Embedded Computers: Spotlight on eTAZ Systems -