When it comes to load cells, making sure their accuracy and reliability is essential for diverse industrial programs. One of the main groups within the area, eTAZsystems, has evolved a complete guide to help users spot a horrific load cell earlier than it reasons any troubles. In this weblog post, we can discover the fundamentals of load cells, not unusual signs and symptoms of a faulty load cell, a way to conduct visible inspections, overall performance checking out, troubleshooting hints, whilst to update a load mobile, preventative measures for longevity, and address regularly asked questions.

Understanding Load Cell Basics with eTAZsystems

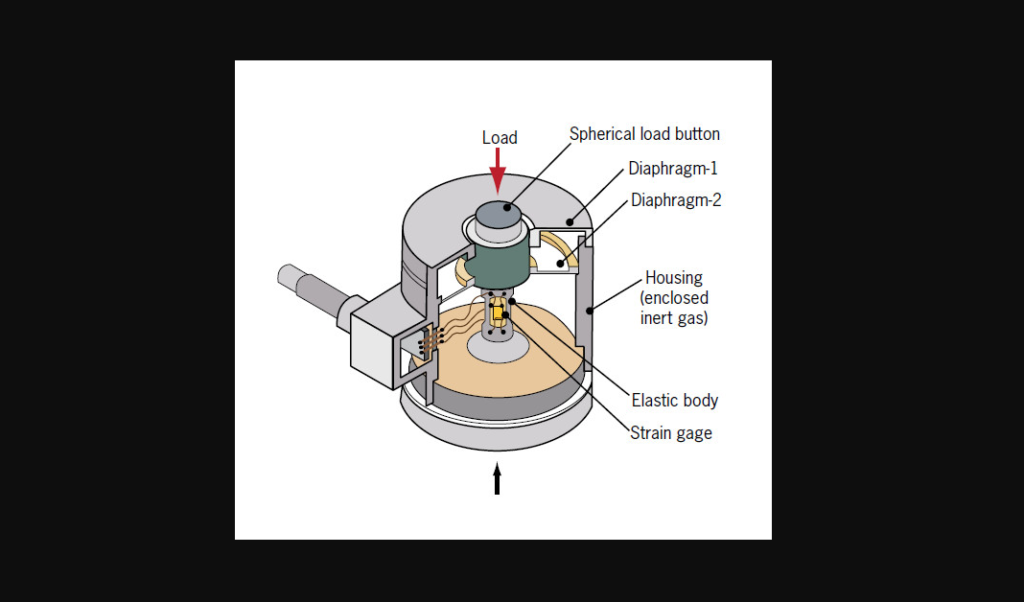

At the heart of commercial measurement and tracking lies the weight cellular, a device pivotal for translating mechanical force into an electrical signal, thus facilitating correct force size. With eTAZsystems at the forefront of innovation, their variety of load cells cater to a mess of industrial needs, emphasizing precision and consistency in outputs. These gadgets function on essential principles that ensure the transformation of bodily load into a quantifiable electrical output, making them indispensable in sectors ranging from production to logistics. By knowledge the operational dynamics and the critical function those additives play, users can higher admire the importance of maintaining the integrity of their load cells. ETAZsystems champions this know-how, imparting now not best advanced load mobile generation but additionally the expertise base important for users to maximize the software and performance of their devices in every software.

Initial Symptoms of a Bad Load Cell

Detecting early signs that indicate a malfunctioning load cell is vital for retaining the accuracy and reliability of your dimension machine. Among the number one signs of a complex load mobile are erratic readings and important deviations in records, that could substantially disrupt the accuracy of your machine’s output. Additionally, any signal drift or sudden changes in output below solid load situations should improve on the spot concerns. These signs propose that the load cellular may not be acting as meant, doubtlessly due to internal or external harm. Keeping a watch out for these irregularities allows for timely intervention, stopping more sizeable problems down the road. Observing the load cellular’s reaction to acknowledged masses and evaluating those to expected outputs is a practical approach in figuring out these early caution symptoms.

Conducting a Visual Inspection: What to Look For

A thorough visual inspection is an integral step in assessing the circumstance of a load cell. It’s the first line of protection against capability malfunctions, supplying an opportunity to capture problems before they increase. During this procedure, eTAZsystems emphasizes the importance of searching out apparent symptoms of bodily damage along with cracks, bending, or corrosion, that may compromise the load cellular’s integrity and overall performance. Equally vital is the inspection of connectors and cables for any symptoms of wear and tear, fraying, or loose connections that would disrupt the signal transmission. Additionally, test for any signs of overloading or mechanical deformation that could have happened in the course of operation. This should indicate that forces have subjected the weight cellular to more than its capacity, leading to permanent damage. Examining the mounting surfaces and alignment is likewise critical, as misalignment can motive misguided readings and undue pressure on the factor.

Performance Testing and Analysis

To undertake effective overall performance trying out and analysis, eTAZsystems recommends a scientific approach to evaluating your load cell’s capability. This technique begins by way of making use of recognized weights to the load cell and recording the electric output it generates. To ensure accuracy in those readings, start with smaller masses and progressively increase to the load cell’s maximum capacity. Monitor the load cellular’s output for linearity and repeatability – key indicators of its health.If the output does not correlate closely with the implemented load, or if variations are observed under identical conditions, it can indicate issues within the load cell’s mechanisms.Additionally, engaging in those checks in distinct environmental conditions can discover sensitivities or potential faults related to temperature or humidity.

Common Faults in Load Cells and Troubleshooting Tips

Load cells can come upon various issues that impair their performance, with commonplace faults consisting of publicity to intense loads main to structural damage, ingress of moisture or chemical substances causing corrosion, and electric interference or grounding troubles affecting sign integrity. To cope with these challenges, eTAZsystems suggests some troubleshooting techniques. For structural damage, visually inspect for any deformities and take into account trying out with acknowledged weights to assess accuracy; if the damage is full-size, replacement may be essential. In instances of corrosion, take a look at for any discoloration or pitting at the load cell’s frame and connections. Preventative measures like making sure proper sealing and environmental protection can mitigate destiny dangers. You can tackle electrical interference, often indicated by erratic alerts, by inspecting and ensuring clean, secure connections, and by employing defensive measures or rerouting cables away from potential sources of interference.

When to Replace Your Load Cell

Furthermore, if you observe a permanent shift in the load cell’s output characteristics during overall performance testing – including a non-linear reaction to applied loads or a loss of repeatability in measurements – this suggests internal component failure that you cannot correct through external adjustments.

Persistent error codes or failure messages from the load cell’s interfacing software, which remain unresolved after addressing potential software and connection issues, also warrant attention for replacement.

Preventative Measures for Load Cell Longevity

Maintaining the longevity and accuracy of load cells is important for the sustained performance of size structures. ETAZsystems highlights the importance of numerous key practices to obtain this purpose. Regular calibration stands at the vanguard of those practices, ensuring that load cells preserve to provide reliable and accurate measurements. Calibration schedules must be adhered to, primarily based on producer suggestions and utilization frequency, to catch any deviations early on. Proper handling is equally essential; users have to keep away from exposing load cells to conditions or loads past their rated capacities to save you stress and capacity damage. Implementing recurring upkeep tests allows for the early detection of problems such as corrosion, bodily damage, or wear and tear on connectors and cables. This proactive technique helps well timed interventions, decreasing the chance of sudden screw ups Basics of Load Cell

Faqs

In our FAQs section, we deal with common questions on load mobile troubles and renovation.

Q: How frequently have to I calibrate my load mobile?

A: Calibration frequency depends on utilization and alertness but generally, it is encouraged to observe producer hints or calibrate bi-yearly.

Q: Can I restore a load cellular myself if it is displaying signs of damage?

A: While minor troubles can be resolved with right information, sizeable harm often requires expert assessment and restore to make sure accuracy and safety.

Q: What’s step one if my load cellular isn’t providing accurate readings?

A: Start with a visual inspection for any bodily damage or connection problems, then proceed to overall performance checking out with regarded weights to diagnose potential inaccuracies.

Q: Are there precise environmental conditions I need to avoid to defend my load mobile?

A: Yes, excessive temperatures, moisture, and corrosive substances can harm your load mobile. Utilizing suitable shielding measures can mitigate these risks.

Remember, keeping your load cellular’s accuracy isn’t pretty much troubleshooting whilst issues get up; it’s also approximately taking preventative measures to make certain its sturdiness and reliability.