When it comes to making sure the accuracy and reliability of load 4 Wire Cells , right assessment is vital. In this weblog post, we are able to delve into the system of checking 4 twine load cells, specifically specializing in eTAZ systems. By following these steps, you can grasp load 4 Wire Cells checks and ensure premier overall performance.

Understanding the Basics of four Wire Load Cells

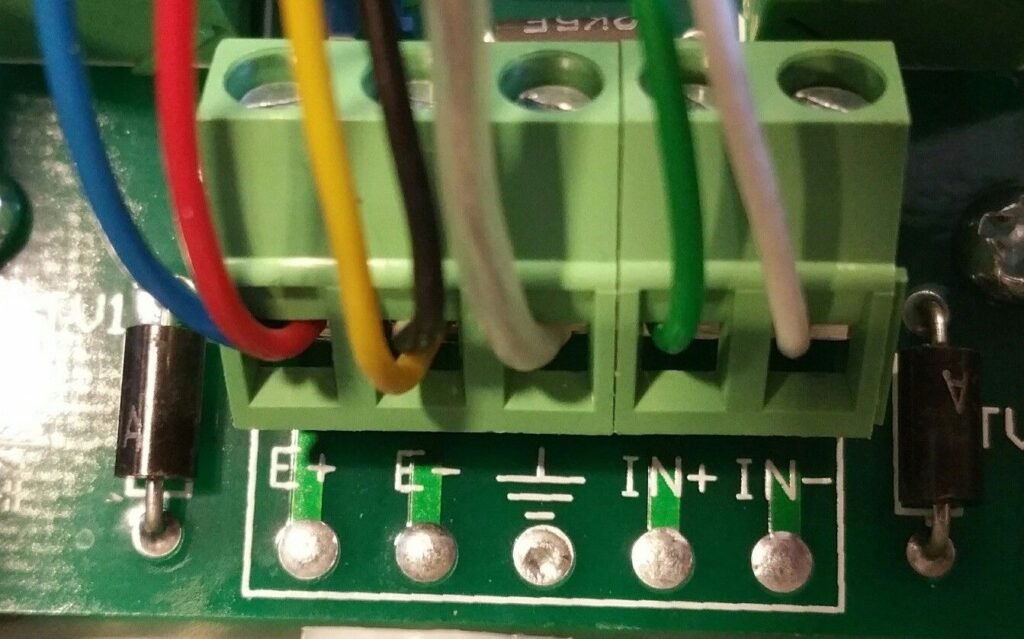

4 cord load cells are instrumental in attaining unique weight measurements in numerous industrial and laboratory settings. These devices perform through changing pressure into an electrical signal via a manner referred to as strain gauging. The unique configuration of 4 wires in those 4 Wire Cells plays a pivotal position of their capability. Two of those wires impart the excitation voltage that powers the weight cell, while the others carry the output signal that corresponds to the burden or pressure applied. This separation enables in minimizing the consequences of resistance modifications inside the lead wires, leading to extra correct readings. Grasping the functionality of those wires and their roles is essential for all people trying to perform comprehensive reviews of four wire load 4 Wire Cells, especially within eTAZ systems.

Preparing for Load Cell Testing

Embarking at the system of testing a 4 wire load mobile needs meticulous instruction to make sure the manner is each green and effective. Begin by using compiling all of the equipment and device needed for the tests, which generally consist of a multimeter for resistance and continuity exams, a strong and calibrated weight for load checking out, and a easy, strong surface to work on. Ensuring the checking out surroundings is free from vibrations and electrical interference is likewise paramount, as these elements can considerably affect the accuracy of your measurements. Familiarize your self with the weight cell’s datasheet or guide; knowledge of its specifications, including its rated potential, output sensitivity, and excitation voltage, is vital. This previous expertise aids in placing the ideal expectations and parameters for the trying out technique.

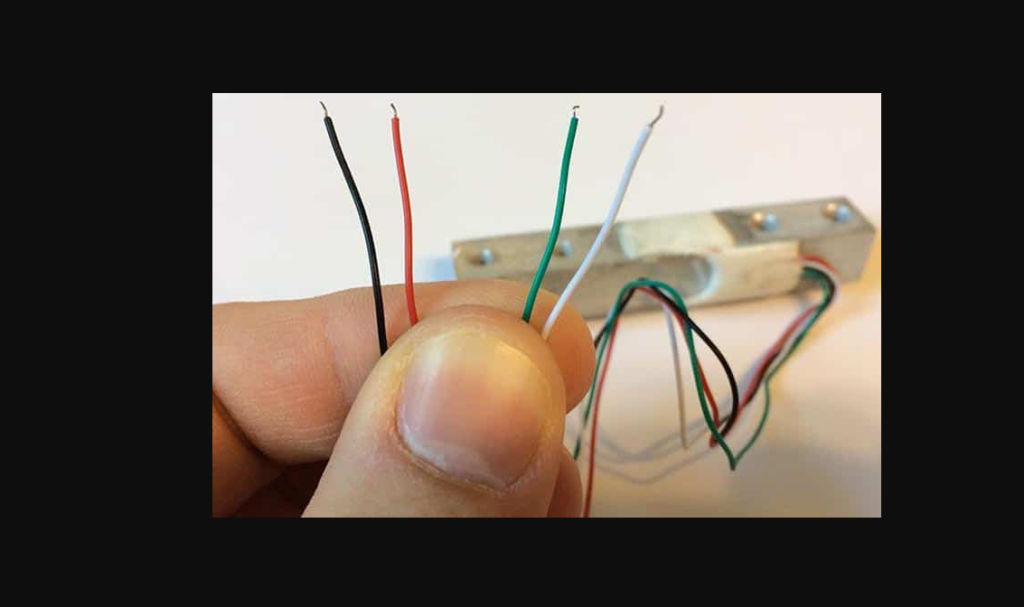

Visual Inspection and Preliminary Checks

The initial step within the load mobile exam entails a radical visual inspection. During this segment, it’s imperative to scrutinize the load cellular for any signs of bodily damage which includes dents, cracks, or deformation, which would possibly compromise its overall performance. Equally vital is to test for corrosion or immoderate put on, especially within the wire connections and junctions, as these could result in erroneous readings or failure beneath load. Additionally, confirm that the burden cell is established securely and efficiently, without a free additives or volatile connections that would affect its operation. This degree additionally consists of ensuring that each one wiring is well linked, with a special attention on the integrity of the four vital wires. Look out for any frayed wires or loose connections that might not simplest pose a hazard to the weight cell’s capability however additionally to protection.

Performing Resistance and Continuity Tests

To correctly perform resistance and continuity checks on a four twine load cellular, a digital multimeter is vital. Begin with the aid of placing the multimeter to measure resistance. Test every pair of wires—the ones specified for excitation and those for the sign—by way of setting the multimeter’s probes across them. The aim is to perceive any surprising resistance values that would indicate a hassle, such as a short circuit or an open circuit in the load mobile’s wiring. Ideally, resistance across the excitation wires should align closely with the load mobile producer’s exact fee. Subsequently, transfer the multimeter to its continuity setting to verify there’s a clean route for electric modern in every of the 4 wires. A non-stop beep from the multimeter indicates proper continuity

To conduct load trying out, begin by way of applying a precisely recognised weight to the load mobile. This action lets in for the size of the output sign, which ought to be meticulously recorded. It’s vital to move-reference this output with the anticipated values as indicated via the weight cellular’s specs. Calibrate to reconcile discrepancies for any variances among these figures, ensuring the burden mobile’s readings align with the recognized carried-out weights.. Calibration entails adjusting the weight cell’s output sign to match the regarded applied force, setting up a baseline for accurate dimension in sensible programs. This system isn’t always only critical for confirming the weight cell’s operational integrity but additionally for retaining the precision required for reliable weight size responsibilities..

Interpreting Test Results and Next Steps

Upon concluding the evaluation checks, it is essential to assess the data accrued in comparison to the load mobile’s technical specifications. This analysis is instrumental in figuring out any deviations that might impact the accuracy or capability of the burden mobile. Should the test outcomes monitor variances from the predicted parameters, an in depth evaluation is essential to pinpoint the root causes, which may encompass troubles related to the load mobile’s physical condition, wiring integrity, or calibration accuracy.

Formulating a plan to deal with these findings is the following vital step. Adjustments may additionally variety from simple recalibrations to more concerned upkeep or maybe alternative of the weight cellular if it fails to fulfill important standards. Documentation of these findings and the moves taken is vital for destiny reference and for keeping a ancient overall performance document of the burden mobile.

Considering the dynamic nature of load cell programs and environments, organising a routine protection and trying out schedule is exceedingly recommended. This proactive method ensures ongoing reliability and overall performance, minimizing the capacity for unexpected downtime or inaccuracies in weight size tasks. This step is mainly vital for eTAZ systems and similar setups in which precision is paramount. Moving forward, regular assessments will serve as a cornerstone for maintaining the operational excellence of 4 twine load cells.

FAQS

What equipment are wished to check a 4 twine load cell?

To take a look at a four cord load cell, you will need a digital multimeter for carrying out resistance and continuity tests, a strong and calibrated weight for load trying out, and a easy, strong paintings surface free from vibrations and electrical interference.

How do I identify the excitation and sign wires in a four twine load mobile?

Typically, the load cellular’s datasheet or manual will specify which wires are for excitation (powering the weight mobile) and which might be for the signal (sporting the output signal). If in doubt, consult the manufacturer’s documentation or technical assist.

What is the importance of performing a visual inspection before trying out?

A visible inspection allows discover any bodily damage, corrosion, or flawed mounting that might affect the burden mobile’s performance, making sure that best load cells in accurate circumstance proceed to extra certain trying out.

Can I recalibrate a load cell myself?

If you have the necessary competencies and gadgets, you can recalibrate a load cell, but it is often recommended to have it done professionally, especially for important applications, to ensure accuracy and compliance with requirements.

What should I do if my load mobile fails the assessments?

If your load cell fails any of the evaluation tests, it may require recalibration, repair, or replacement, relying on the nature of the problem. Consult with a expert or the producer for the fine route of motion.