Introduction to Piezoceramic Transducers

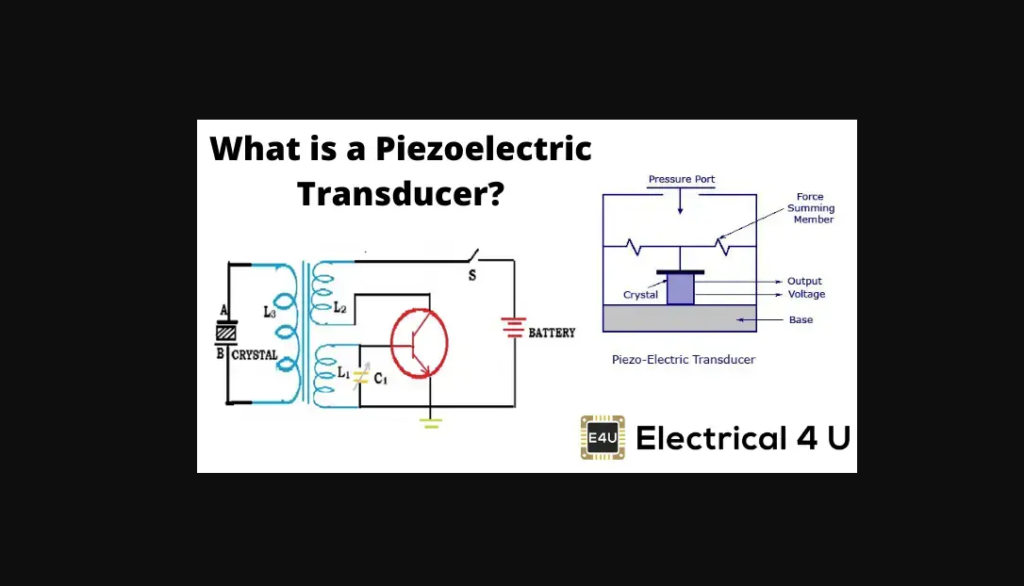

Piezoceramic transducers are devices that convert mechanical energy into electrical energy (and vice versa) using the piezoelectric effect. These transducers play a crucial role in various fields, including medical imaging, industrial sensing, and actuation. The heart of these devices is a piezoceramic material, often lead zirconate titanate (PZT), known for its high efficiency, stability, and durability.

eTAZ systems design piezoceramic transducers, experts must have knowledge in several areas, including material science, mechanical design, electronics, and signal processing. They aim to create transducers that specifically meet the needs of their intended applications, whether these require high sensitivity for medical purposes or durability for industrial use.

Our Piezoceramic Transducer Design Services

We offer comprehensive design services for piezoceramic transducers, serving a wide range of industries, from healthcare to aerospace. Our services cover every stage of development, from initial concept to final production. Here’s what we provide:

Concept Development and Feasibility Studies

Understanding Client Requirements: We start by thoroughly understanding what you need. This involves detailed discussions and feasibility studies to ensure that the design will meet all your requirements.

Material Selection: We help you choose the right piezoceramic material, considering factors like sensitivity, frequency range, and environmental conditions.

Mechanical Design and Simulation

Our team creates detailed transducer models using advanced CAD software, ensuring the design is manufacturable and meets all mechanical specifications.

Finite Element Analysis (FEA): We perform FEA to predict how the transducer will behave mechanically and electrically under different conditions, optimizing it for performance and durability.

Electrical Design and Circuit Integration

Impedance Matching: Proper impedance matching is crucial for the efficiency of piezoceramic transducers. Our electrical engineers design circuits that ensure optimal energy transfer.

Signal Conditioning: We create signal conditioning circuits that amplify and filter the transducer’s output, ensuring accurate and reliable data.

Prototyping and Testing

Prototype Fabrication: After finalizing the design, we create prototypes using precise manufacturing techniques. These prototypes are rigorously tested to ensure they meet all design specifications.

Performance Testing: We conduct extensive tests to measure sensitivity, frequency response, and durability, ensuring that the transducer will perform reliably in its intended application.

Manufacturing Support

Production Optimization: We help scale the design for mass production, ensuring the manufacturing process is cost-effective and produces high-quality products.

We implement strict quality control measures during production to maintain consistency and reliability in every unit.

Customization and Consulting

Custom Designs: For clients with unique needs, we offer fully customized transducer designs. Our team works closely with you to develop solutions tailored to your specific requirements.

Technical Consulting: We also provide consulting services for companies looking to improve their existing transducer technologies or develop new piezoceramic applications.

Applications of Piezoceramic Transducers

Piezoceramic transducers are used in various applications across different industries:

Medical Imaging: In ultrasound imaging, these transducers generate high-frequency sound waves to create images of internal body structures, making them essential for diagnostic imaging.

Industrial Sensing: They are used in non-destructive testing (NDT) to detect flaws, monitor structural health, and measure physical parameters like pressure and vibration.

Aerospace and Defense: These transducers are used in sonar and guidance systems, where reliability and precision are critical.

Consumer Electronics: Piezoceramic transducers are also found in devices like microphones, speakers, and vibration sensors, providing reliable performance and durability.

FAQs About Piezoceramic Transducer Design Services

What materials are commonly used in piezoceramic transducers?

Depending on the application, manufacturers also use other materials like barium titanate and lead titanate. They prefer PZT because of its high efficiency, stability, and versatility.

How do you ensure the reliability of a piezoceramic transducer in harsh environments?

We select durable materials, design robust mechanical structures, and conduct extensive environmental testing to ensure performance under extreme conditions.

Can you design custom transducers for specific applications?

Yes, we specialize in custom designs tailored to meet specific client requirements, including frequency range, sensitivity, and form factor.

What is the typical lead time for developing a new transducer?

The lead time varies depending on complexity but typically ranges from a few weeks to several months, covering concept development, prototyping, and testing.

How do you optimize the design for mass production?

We simplify the manufacturing process, choose cost-effective materials, and ensure the design is easy to assemble and test, collaborating with manufacturers to streamline production.

What testing methods do you use to verify transducer performance?

We use impedance analysis, frequency response testing, environmental testing, and endurance testing to ensure the transducer meets all performance criteria.

Can you assist with integrating the transducer into my existing system?

Absolutely. We offer integration support, including interface circuit design, software support, and technical guidance to ensure optimal performance.

What are the key factors to consider when selecting a piezoceramic transducer for my application?

Consider the frequency range, sensitivity, impedance, environmental conditions, and mechanical constraints. Our team can help you evaluate these factors.

Do you offer post-design support?

Yes, we provide comprehensive post-design support, including technical assistance, troubleshooting, and ongoing consulting to ensure optimal performance.

What industries do you primarily serve with your piezoceramic transducer design services?

We serve a wide range of industries, including medical, industrial, aerospace, defense, automotive, and consumer electronics.

Conclusion

Piezoceramic transducers are vital components in many advanced technologies, offering the precision and reliability needed for a wide range of applications. Our design services are tailored to help clients develop transducers that meet their specific needs, ensuring high performance, durability, and cost-effectiveness. “We will support you every step of the way as you develop a new transducer or optimize an existing design.

contact us

Furthermore greater statistics about our Piezoceramic Transducer Design Services about your unique assignment desires, please touch us:

Office Address: Office # 9, First floor, Business Incubation Center SSC, University of Engineering and Technology, Lahore.

Phone: +923234767694

Email: info@etazsystems.Com

At eTAZ Systems, we deliver innovative and reliable Piezoceramic Transducer Design Services that drive the success of our customers’ projects.Reach out to us these days to look how we are able to assist carry your electronic designs to lifestyles.

Pingback: Explore How AC and DC Power Differ -