Bimetallic stemmed thermometers are used in many industries, from meal processing to HVAC systems. Their specific design permits accurate temperature readings and durability in harsh environments. In this blog, we can discover a bimetallic stemmed thermometer’s versatility and critical programs.

Understanding the Bimetallic Stemmed Thermometer

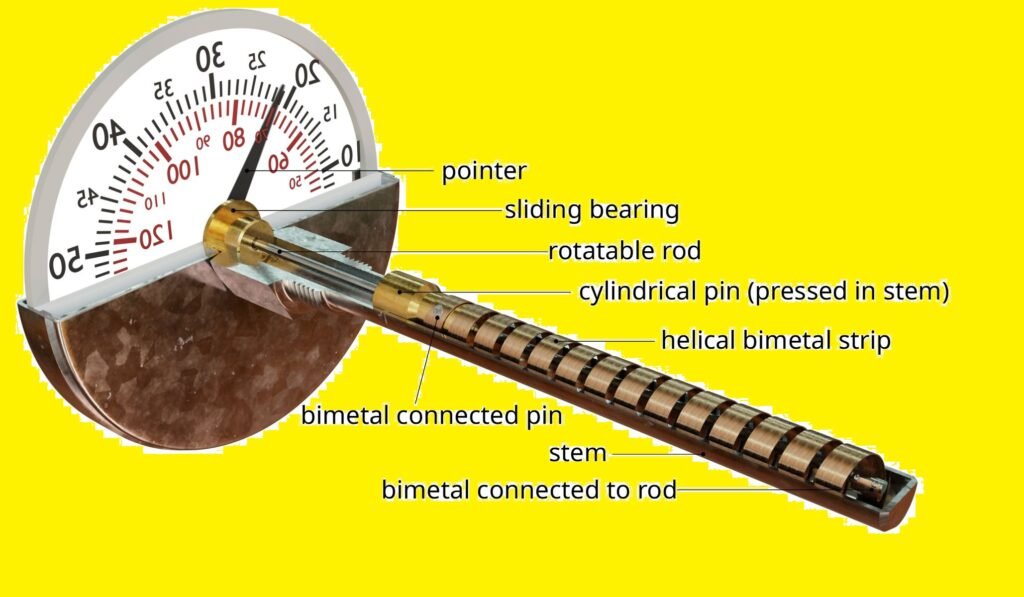

At the coronary heart of the bimetallic stemmed thermometer’s functionality lies its creative production, which marries distinct metals into a single coil. These metals are selected for his or her differing expansion fees whilst heated. As temperature increases, the disparity in enlargement causes the coil to transport, a movement ingeniously translated into a precise temperature reading displayed on the thermometer’s dial. This mechanism allows the tool to provide speedy responses to temperature adjustments and ensures the accuracy of its readings. The creation is strong, permitting the thermometer to perform correctly in numerous environments, from the rigorous situations of business manufacturing floors to the managed atmospheres of food processing flora. The precision and reliability of the bimetallic stemmed thermometer stem from its simple yet powerful layout, which avoids the need for outside strength sources or complex electronic components.

The eTAZ System Explained

The eTAZ systems gadget represents a jump ahead in temperature tracking and control technologies, integrating the confirmed reliability of bimetallic stemmed thermometers into its middle. This state-of-the-art system reveals its utility chiefly in industrial environments where the margin for mistakes in temperature measurements is negligible. By leveraging the inherent accuracy and rapid reaction of bimetallic stemmed thermometers, the eTAZ device offers a progressive solution for actual-time temperature oversight.

This gadget is engineered to provide continuous monitoring, handing over on-the-spot alerts in the event of temperature deviations from predetermined norms. Such competencies are essential when retaining particular temperature tiers and are indispensable to protection and process performance. For example, in chemical production, where reactions are surprisingly temperature-established, the eTAZ machine guarantees that situations remain inside safe operational parameters, thereby stopping doubtlessly hazardous conditions.

Moreover, the eTAZ device’s layout incorporates the harsh realities of industrial settings. It harnesses the sturdiness of bimetallic stemmed thermometers, recognized for their resistance to corrosive substances and potential to function in severe temperatures. This resilience makes the eTAZ machine a fundamental tool in environments that might compromise lesser instruments.

By integrating bimetallic stemmed thermometers, the eTAZ device stands at the vanguard of temperature management generation, imparting extraordinary precision and reliability. It exemplifies how conventional-size equipment, while blended with contemporary structures, can meet the evolving demands of business temperature tracking.

Critical Applications of the Bimetallic Stemmed Thermometer

The bimetallic stemmed thermometer is used fundamentally throughout several key industries, showcasing its adaptability and vital role in ensuring safety, high quality, and efficiency. In the world of meal processing, these thermometers play a pivotal function in verifying that meals reach secure cooking temperatures, which is essential for stopping foodborne ailments. This is crucial in commercial kitchens and meal manufacturing, where consistency and safety are paramount.

HVAC systems benefit drastically from bimetallic stemmed thermometers’ suitable and sturdy nature. They are crucial for monitoring the temperatures of air and water, ensuring environments are kept at snug levels while optimizing strength performance. Furthermore their capacity to resist fluctuating conditions without compromising accuracy makes them a go-to choice for HVAC technicians.

In commercial contexts, the thermometer’s application extends to tracking machinery and operational systems. The early detection of abnormal temperature modifications can prevent gadget failure, ensuring uninterrupted production processes. This is especially critical in sectors in which equipment operates continuously and under high-temperature situations.

Each utility underscores the thermometer’s versatility, supplying an easy but powerful solution for temperature tracking across diverse environments. Its massive usage underlines the instrument’s reliability, underpinning its endured relevance in modern industrial and business operations.

Advantages of Using a Bimetallic Stemmed Thermometer in the eTAZ System

Integrating a bimetallic stemmed thermometer inside the eTAZ gadget brings benefits, often enhancing operational performance and safety. Moreover the core electricity of this aggregate lies inside the thermometer’s inherent resilience to environmental stressors. Constructed to bear the trials of excessive business conditions, it can reliably measure temperatures in settings that would harm or degrade less sturdy gadgets. Its compatibility with the stressful environments of commercial programs ensures that temperature tracking stays regular and correct, a vital issue in keeping procedures manipulated and a fantastic guarantee.

Another key advantage is the bimetallic thermometer’s rapid reaction time. This characteristic is crucial for the eTAZ machine’s capability to detect and react to temperature variances unexpectedly, facilitating instantaneous corrective actions. Such an activated response is imperative in methods wherein even minor temperature fluctuations can have significant repercussions, from affecting product quality to posing protection risks.

Additionally, the simplicity and mechanical nature of the bimetallic stemmed thermometer, free from the need for electric energy, enhance the eTAZ system’s reliability. This guarantees that temperature tracking and management can continue even in eventualities where electricity availability is inconsistent or in the face of digital element failures.

This synergy between the bimetallic stemmed thermometer, and the eTAZ device amplifies both strengths, presenting a powerful, reliable, robust solution for temperature tracking.

Maintenance and Calibration for Optimal Performance

Maintaining the precision of a additionally bimetallic stem thermometer is paramount for making sure it keeps supplying reliable and correct temperature readings. Regular calibration is essential; this procedure benchmarks the thermometer’s measurements against a known temperature range to verify its accuracy. The thermometer’s readings may remain stable with periodic calibration, leading to capacity inaccuracies and compromising safety and high quality in vital packages.

In addition to calibration, ordinary protection is essential to maintaining the thermometer’s capability. This entails cleansing the thermometer to remove any buildup of materials that could interfere with its responsiveness to temperature adjustments. Particles and debris can impede the bimetallic coil, affect the stem, and skew readings. It’s also essential to investigate the thermometer for any signs and symptoms of bodily damage that would impair its performance, including dents or corrosion, specifically given the disturbing environments wherein those devices often operate.

It is recommended to implement a schedule for each calibration and preservation. Such practices not only extend the lifespan of the thermometer but also uphold the integrity of the strategies it monitors. Adherence to these methods ensures that the bimetallic stemmed thermometer remains a dependable device for accurate temperature measurement, reinforcing its function in diverse business and industrial settings.

Future Trends in Temperature Measurement and the Role of Bimetallic Thermometers

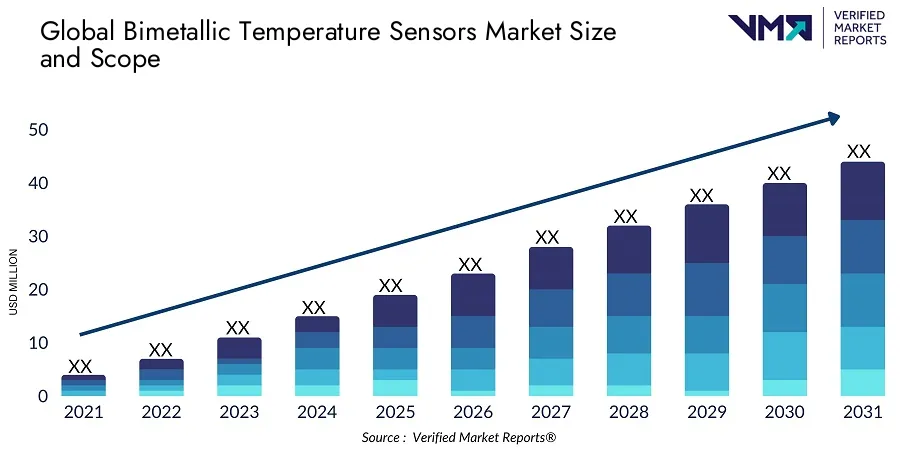

Temperature size technology is moving towards a more advanced method that embraces the capabilities of developing technology while utilising the built-in advantages of conventional tools like bimetallic thermometers. Secondly, One example of a well-sized fashion is the incorporation of those time-tested devices into Internet of Things (IoT) networks. This combination makes it possible to track temperatures remotely and in real time in a variety of environments, from industrial settings to artificially created environments, which enhances both operational effectiveness and comfort.

Furthermore, advancements in textile science should improve the usefulness and precision of bimetallic thermometers. Researchers are investigating new metal alloys and composite materials to provide improved temperature responsiveness, increased durability under extreme situations, and less susceptibility to environmental influences that could distort measurements. These developments could increase the range of applications for bimetallic thermometers, making them

Conclusion

In wrapping up our exploration of the bimetallic stemmed thermometer, it’s clear that its uses amplify far past mere temperature measurement. Firstly, This tool’s adaptability across various industries—from food safety to HVAC systems and its vital integration into superior systems like the eTAZ- underscores its irreplaceable value. Its sturdiness, simplicity, and precision make it a steadfast best friend in environments where accuracy is non-negotiable. As we look into the future, the ability of these thermometers to interface with emerging technology and materials heralds a brand-new technology of efficiency and sustainability in temperature monitoring. Committing to everyday renovation and calibration assures the sturdiness and reliability of the bimetallic stemmed thermometer. This enduring relevance in each present-day destiny program solidifies its role as a cornerstone of temperature dimension generation.