Introduction

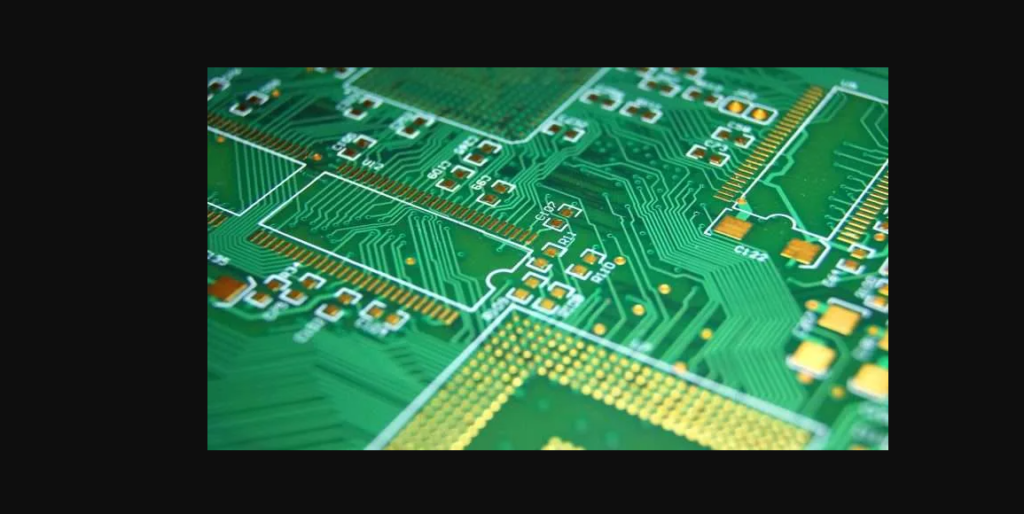

PCB (Printed Circuit Board) assembly is a fundamental process in electronics manufacturing, where electronic components are integrated onto a PCB to form a complete, working circuit. At eTAZ Systems, we are experts in delivering top-quality PCB services, ensuring that our clients receive solutions that are both reliable and cost-effective, tailored to meet their specific requirements.

What is PCB Assembly?

PCB is the process of attaching electronic components to a PCB, transforming it from a simple board with electrical pathways into a fully functional electronic device. This process generally falls into two categories:

Surface Mount Technology (SMT): In SMT, components are mounted directly onto the PCB’s surface. This method is popular due to its efficiency, compact component sizes, and the ability to place components on both sides of the PCB.

Through-Hole Technology (THT): THT entails placing component leads through apertures in the PCB and securing them by soldering on the opposite side.

This technique is often used for components requiring additional mechanical support but is less space-efficient compared to SMT.

The PCB Assembly Process

PCB assembly involves several critical steps:

Solder Paste Application: A stencil is used to apply solder paste onto the PCB. This paste contains small solder balls that will later bond to the component leads and PCB pads during the soldering process.

Component Placement: Components are placed onto the PCB, either manually or with automated pick-and-place machines. Accurate placement is crucial for the proper functioning of the final product.

Soldering: We heat the solder paste in a reflow oven or through wave soldering, causing it to melt and create a solid connection between the component leads and PCB pads.

Inspection and Testing: After soldering, we thoroughly inspect and test the PCB to ensure that we have correctly placed and soldered all components, and that the circuit operates as intended.

Rework and Repair: We address any issues found during inspection through rework and repair, which may involve removing and replacing components or correcting soldering defects.

Why Choose eTAZ Systems for PCB Assembly?

At eTAZ Systems, we offer exceptional PCB assembly services, and here’s why you should consider us:

Expertise: Our team has extensive experience in PCB assembly for various industries, including consumer electronics, automotive, industrial automation, and telecommunications.

Advanced Technology: We use cutting-edge equipment and technologies to ensure precision and efficiency in every assembly.

Quality Assurance: We adhere to strict quality control measures, including thorough inspection and testing, to ensure every PCB meets the highest standards.

Custom Solutions: We provide tailored PCB assembly solutions, from prototyping and small-batch production to large-scale manufacturing.

Cost Efficiency: Our efficient processes and competitive pricing ensure high-quality assembly services within your budget.

FAQs About PCB Assembly

What is the difference between SMT and THT?

SMT involves placing components directly onto the PCB surface, while THT inserts leads through PCB holes and solders them on the other side. SMT is more space-efficient and suitable for high-density boards, whereas THT offers stronger mechanical connections.

What are the advantages of SMT over THT?

SMT provides:

Smaller component sizes

Higher component density

Improved automation

Better performance due to shorter connection paths

What are common defects in PCB assembly and how are they addressed?

Common defects include:

Solder Bridges: Unintended solder connections; addressed during inspection.

Component Misalignment: Corrected through rework.

Cold Solder Joints: Weak joints fixed with reflow or hand soldering.

Missing Components: Identified and replaced through inspection.

How does eTAZ Systems ensure the quality of its PCB assemblies?

We employ:

Automated inspection systems

Functional testing of each PCB

Visual inspection by experienced technicians

Compliance with industry standards

What types of PCBs can eTAZ Systems assemble?

We can assemble:

Single-Sided PCBs

Double-Sided PCBs

Multilayer PCBs

Flexible PCBs

Rigid-Flex PCBs

What is the typical turnaround time for PCB assembly at eTAZ Systems?

Turnaround time varies with complexity and volume. Prototypes typically take 1-2 weeks, while larger production runs have adjusted timelines.

Can eTAZ Systems handle both prototype and production PCB assembly?

Yes, we handle both prototype and production , providing flexible solutions for small-batch prototypes and large-scale production.

What materials and components are used in PCB assembly?

Common materials and components include:

PCB Substrates (FR-4, polyimide, ceramic)4

Solder Paste

Electronic Components (resistors, capacitors, ICs)

Soldering Materials (solder wires, solder balls)

Conclusion

PCB assembly is essential for turning bare boards into functional electronic devices. At eTAZ Systems, we are dedicated to providing high-quality PCB assembly services that meet top performance, reliability, and efficiency standards. Whether for prototyping or large-scale production, our expert team and advanced technology ensure your project meets your exact specifications. Reach out to us now to discover more about our PCB assembly solutions and how we can support your upcoming project.