If you have ever puzzled how to check a load cell, you’re within the right place. Load cells are essential additives in various commercial and commercial packages, accountable for measuring weight and force. Checking them frequently guarantees accuracy and stops malfunctions that might result in costly downtime. In this last guide, we are able to stroll you thru the system of checking load cells, that specialize in eTAZ systems structures.

Understanding the Basics of Load Cells and Their Importance

At the coronary heart of severa precision dimension packages lies the weight cellular, a complicated transducer that converts a mechanical pressure into an electrical sign. These devices are crucial in a wide array of sectors, consisting of however now not confined to production, agriculture, and transportation. The accuracy of weight or pressure measurements furnished through load cells can drastically affect the outcome and efficiency of operations within those industries. Given their critical role, making sure that these components function efficiently through ordinary maintenance and assessments is vital. Such diligence no longer best helps the transport of precise readings but also aids in avoiding operational errors that could have a long way-attaining implications. Understanding how load cells operate and recognizing their significance can’t be overstated, as it forms the basis for implementing effective monitoring and maintenance routines.

Common Signs of Load Cell Malfunctioning or Failure

Recognizing the early indicators of a load cellular problem is essential for maintaining most advantageous overall performance and accuracy in size packages. The most evident signs and symptoms that a load cell isn’t functioning effectively include unexplained fluctuations in measurement readings. Such inconsistencies might happen as unexpected jumps or drops in weight measurements, indicating ability troubles. Additionally, a glide in readings over the years, wherein the measured values slowly shift faraway from the proper weight even when the load hasn’t modified, shows an inner difficulty with the weight cell. Physical exam is similarly important; visible harm along with cracks, deformation, or signs and symptoms of corrosion on the load cellular frame or its connecting cables can impair its functionality.

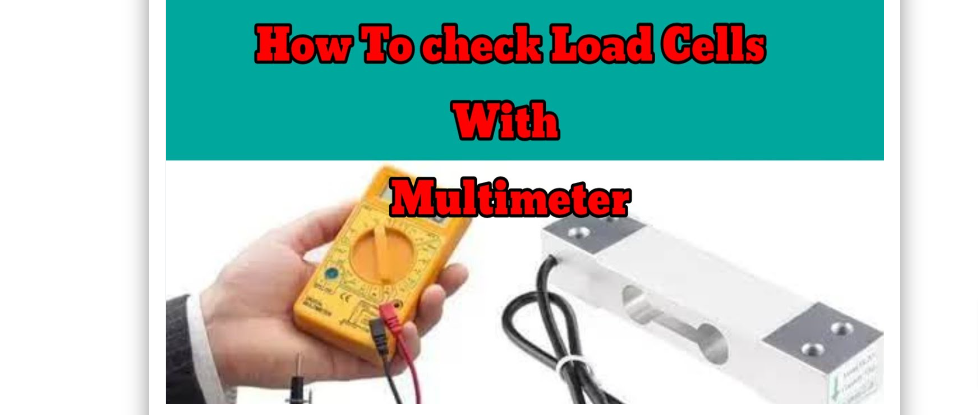

Preparing to Check Your Load Cell: What You Need

To provoke the process of analyzing your load cell, it is imperative to collect the right set of tools and substances. Essential to this practise is a reliable multimeter, which performs a pivotal position in undertaking electric exams. Additionally, having calibration weights to hand is essential for verifying the accuracy of the load cellular’s measurements. You likewise need a spanner wrench to examine and adjust the physical setup of the load cell to ensure it is effectively mounted and aligned. Furthermore, relying at the specific requirements mentioned by way of the weight mobile producer, you could want to procure specialized gear or system. Prioritize safety by way of adhering to all recommended precautions and guidelines at some point of the inspection process.

Step-by means of-Step Guide to Physically Inspecting the Load Cell

Begin your bodily inspection with the aid of cautiously examining the weight cellular for any obvious signs and symptoms of harm, consisting of dents, cracks, or any form of deformation. Pay close interest to the integrity of the cables and connectors, searching out free, frayed, or broken wires that could have an effect on overall performance. Utilize a spanner wrench to affirm that the burden mobile is installed securely and aligned correctly, ensuring it isn’t always concern to undue stress or misalignment that might impact its accuracy. Inspect the mounting hardware for any signs of wear or improper installation that would necessitate changes. It’s essential in the course of this step to deal with the burden cell and its components lightly to avoid introducing any new troubles.

How to Perform an Electrical Check on Your Load Cell

To carry out an effective electrical inspection of your load cell, begin together with your multimeter set to measure resistance. Cross-reference the burden cell’s resistance studying with the specs furnished by the manufacturer to make sure they align. If the resistance tiers deviate, it is able to imply an internal trouble with the weight cell. Next, measure the output voltage while the weight cellular is under a nominal load. This analyzing must also suit the manufacturer’s documented range for proper capability. Deviations in voltage output signal capability troubles that could impact overall performance. During those exams, make sure that the burden mobile connections are secure and that there is no visible damage to the wiring, as those elements could have an effect on the accuracy of your readings.

Advanced Troubleshooting Techniques for eTAZ Systems

For the ones using eTAZ systems, diving deeper into troubleshooting techniques is crucial while preliminary assessments do no longer solve load cellular troubles. Delving into system-unique diagnostics, recollect acting a comprehensive evaluation of calibration settings to make certain they align with operational necessities. A zero balance take a look at can screen discrepancies among anticipated and real output, pointing to ability calibration drifts or mechanical alterations affecting overall performance. Additionally, exploring modifications in sign conditioning parameters would possibly discover hidden problems affecting statistics integrity. While adjusting those settings, consider of the complex balance among sensitivity and accuracy, as wrong modifications can introduce size mistakes. For complex situations that extend past basic troubleshooting, consulting the producer’s technical assist or enlisting the understanding of a professional technician may also offer targeted insights into resolving system-unique challenges without compromising the device’s integrity.

When to Seek Professional Calibration or Replacement

Encountering ongoing issues with a load cell that resist all troubleshooting tries alerts the need for expert intervention. Professional calibration is important while in-residence fixes fail to repair accuracy or whilst there’s uncertainty approximately the load mobile’s performance. Technicians geared up with specialised information and gear can correctly diagnose issues, ensuring the weight cellular meets precise size standards. Similarly, if a load cell shows symptoms of irreversible damage or constant inaccuracy, it can be beyond repair, necessitating substitute. Engaging with specialists no longer best facilitates in resolving complex problems however also in verifying that the weight cellular operates within its superior parameters. This step is vital, specifically in programs in which precision is paramount, and can assist avoid the greater extensive expenses associated with incorrect measurements or operational screw ups.

Maintaining Your Load Cells for Longevity and Accuracy

Ensuring the extended efficiency and precision of your load cells hinges on adopting a proactive approach to protection. Consistently keeping the load cell and its environment clean, without any contaminants or debris, is fundamental. Dust, moisture, or any overseas materials can compromise the weight cell’s capability through the years. Regular inspections are critical; those not best involve checking for bodily damage or put on however also include monitoring the device’s performance for any deviations from expected measurements. Adherence to a based preservation schedule, as encouraged with the aid of the weight mobile manufacturer, is vital. This time table frequently outlines the frequency of specified inspections and calibration exams necessary to preserve most desirable overall performance. By diligently following these guidelines, you ensure that your load cells stay dependable and correct, hence safeguarding the integrity of your operations.

FAQS

When it involves the frequency of checking load cells, the first-class practice is to behavior exams periodically, with the exact c programming language various primarily based on the application’s demands and the environmental situations. For preferred steerage, evaluations carried out on a quarterly or semi-annual basis are ok for most conditions. However, for load cells running in harsh environments or beneath non-stop, excessive-load situations, greater common checks can be essential to make certain ongoing accuracy and reliability.

Regarding calibration, whilst fundamental verification and minor modifications can regularly be treated in-residence, the procedure of calibrating load cells to ensure they meet specific size standards normally requires professional information. Calibration involves comparing the burden mobile’s output to a acknowledged load and making the important modifications. This technique is crucial for keeping accuracy and ought to ideally be accomplished by certified technicians. These specialists have get entry to to specialised system and possess the know-how required to make certain that the calibration is performed effectively, adhering to enterprise and regulatory standards. For those without the needful training or gadget, attempting to calibrate load cells independently can also result in inaccuracies, doubtlessly compromising the integrity of the measurements and the operation’s universal performance. Therefore, searching for professional calibration offerings is recommended for premier performance and compliance.