Have you ever questioned how your lavatory scale correctly measures your weight or how business machines can exactly determine the force they exert? eTAZ systems the solution lies in load cells. But how do load cells work?

In this blog post, we will delve into the intricacies of load cells, uncover the basic principles behind their operation, explore the different types available, and discuss their various applications. Let’s get started on demystifying the world of load cells.

Unveiling the Mystery: The Basic Principle of Load Cells

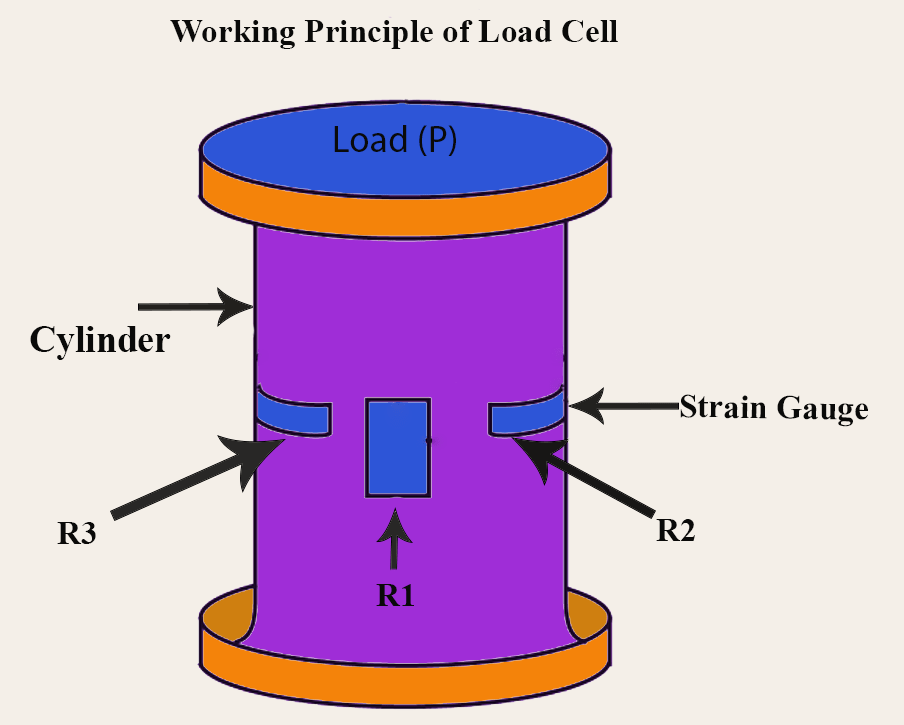

A load cellular transforms bodily force into a quantifiable electric signal, bridging the tangible and the virtual. This transduction procedure is based at the precept of cloth deformation under load. Strain gauges play a pivotal role within the load cell’s structure.

We finely tune these components to discover the slightest deformation inside the load cell’s metal body.

These strain gauges change electrical resistance upon utility of pressure, a phenomenon meticulously calibrated to be without delay proportional to the force exerted.

The system then translates this variation in resistance into an electrical signal.

This sign is a digital fingerprint of the force, bearing in mind particular size and evaluation. Through this elegant mechanism, load cells provide a reliable approach for gauging force and weight throughout many applications, from regular devices to complicated industrial equipment.

Peering Into the Heart: Different Types of Load Cells

Diversity is critical to assembly the large application necessities within load cells. Bending beam load cells are tailor-made for scenarios desiring specific weight measurements, including business scales and conveyor structures. Their layout leverages the bending motion to degree force, making them quite effective in those environments.

When evaluating shear beam load cells, they are designed to handle large loads and are often found in commercial weighing systems and tank weighing systems.

. Their robustness and reliability in excessive-ability programs lead them to a pass-to preference.

For situations in which force is applied linearly, use tension load cells. They are typically utilized in crane scales and other vertical force measurement systems.

Each kind of load cells gives particular characteristics and benefits, offering the versatility needed to measure force and weight correctly in genuinely any situation.

The Signal Path: Understanding Load Cell Output

When a load mobile detects force, it interprets this bodily strain into an electrical sign. However, this preliminary sign normally desires to be greater crucial for direct analysis. It calls for amplification to a extra sizable degree, making it interpretable for in addition processing. This step, vital in the journey from pressure to facts, entails state-of-the-art signal conditioning.

This procedure filters out external noise and capability interference that would skew the signal, ensuring the purity and accuracy of the captured records.

Amplification and conditioning prepare the burden mobile’s output for meaningful interpretation through direct digital presentations or integration into broader information evaluation systems. This refined signal offers a specific representation of the carried out force, facilitating accurate measurements and enabling customers to derive treasured insights from the records gathered.

In Real Life: Applications of Load Cells

Load cells find their place in an outstanding array of settings, showcasing their adaptability and essential position in numerous industries. In production, these gadgets are necessary for ensuring that additives meet precise specs, thus making sure product pleasant and safety. Agricultural sectors rely upon load cells work for tracking feed distribution and optimizing yield even as preserving sustainability. Health and health industries comprise them into system to offer remarks on overall performance metrics, supporting users track their progress with precision. In transportation and logistics, load cells are vital for cargo weight verification and pivotal in maintaining automobile protection and compliance with criminal weight limits. The construction industry utilizes load cells to display cloth forces at some point of trying out, ensuring systems can resist environmental stresses.

In the entertainment industry, technicians use load cells in stage rigging to ensure the safety of performers and audiences alike.

Getting Technical: Accuracy, Sensitivity, and Calibration

The precision with which a load cell plays is paramount, as it immediately influences the reliability of weight or force measurements. This precision hinges on two vital traits: accuracy and sensitivity. Accuracy refers back to the closeness of the measured value to the real price, even as sensitivity is the load cell’s potential to stumble on minute adjustments in weight or force. Calibration is crucial for exceptional-tuning these attributes, ensuring that load cells yield dependable and regular readings. This calibration method includes subjecting the burden mobile to acknowledged weights or forces and adjusting its output to healthy the implemented values as it should be. External factors, together with environmental shifts consisting of temperature changes or vibrations, can influence load cellular overall performance. Therefore, incorporating considerations for these variables into the calibration and ongoing use of load cells is important for maintaining their accuracy through the years.

Challenges and Solutions: Overcoming Load Cell Issues

Navigating the limitations that load cells come across requires a comprehensive expertise of their ordinary troubles and the techniques to cope with them. Drift, characterised with the aid of a slow shift within the load mobile’s signal over time, can introduce dimension inaccuracies.

Counter this by imposing routine recalibrations and monitoring the system for signs of change.

The moderate deformation experienced beneath sustained load necessitates the use of load cells designed with substances and systems that minimize this effect, alongside periodic recalibration to accurate any deviations. Hysteresis, the variance determined in the sign while loading and unloading, calls for precision in the load cellular’s layout and the application of consistent calibration practices.

The Future of Force Measurement: Innovations in Load Cell Technology

In the swiftly evolving panorama of load cell technology, present day advancements are paving the manner for even greater specific and convenient force measurement answers.

Innovations like wireless and miniature load cells are revolutionizing force and weight measurement, providing unparalleled flexibility and integration capabilities.

Wireless technology in load cells introduces the advantage of remote monitoring, getting rid of bodily wiring constraints and permitting information series from challenging or dynamic environments. On the opposite hand, Miniature load cells are making full-size strides in applications where space is at a top rate, offering correct measurements in compact, unobtrusive codecs ideal for embedded structures in scientific devices, robotics, and wearable generation. Furthermore, the arrival of sensible load cells equipped with advanced digital communique functions marks a big leap forward. These clever devices can system and transmit statistics in actual-time, facilitating seamless integration with IoT systems and cloud-based totally analytics structures.

FAQS

This FAQs section will address common inquiries approximately load cells, imparting concise and informative solutions to beautify your knowledge.

Q: How do load cells work?

A: Load cells paintings with the aid of changing a force into an electrical sign. This procedure involves pressure gauges, which exchange resistance when deformed by way of the force applied to the burden cell.

This resistance change converts into an electrical signal that quantifies the applied pressure or weight.

Q: Can load cells measure both pressure and weight?

A: Yes, load cells can measure both pressure and weight.

The principle of operation remains the same, wherein it transforms the applied force, such as the gravitational pull on an object’s mass (weight), into an electrical signal for measurement.

Q: How do we calibrate load cells?

A: Load cells are calibrated via applying recognized weights or forces and adjusting the output to match those appropriately. Calibration guarantees the load cellular’s readings remain accurate and constant over the years, accounting for temperature adjustments and lengthy-time period use.

Q: What factors affect load cell accuracy?

A: Factors that can affect the accuracy of a load cellular include environmental conditions together with temperature versions, mechanical setups like mounting and alignment, and electric interference. Regular calibration and proper set up are important to retaining accuracy.