Strain gauge load cells work are a essential issue in many business and business weighing packages. They provide accurate, dependable measurements which might be important for various procedures, from manufacturing to transportation. In this comprehensive article, we will discover how strain gauge load cells paintings, Addition the generation behind them, and the blessings they offer, equally, particularly focusing at the know-how and improvements from eTAZ Systems.

Introduction to Load Cells

This conversion is essential for measuring weights or forces in extraordinary environments. There are several styles of load cells, together with hydraulic, pneumatic, and pressure gauge load cells. Among these, people extensively use pressure gauge load cells the most due to their precision, versatility, and robustness.

What is a Strain Gauge?

Equally, when pressure deforms a fabric, the pressure gauge connected to the fabric deforms as well. However, the pressure gauge deforms, altering its electric resistance, and we can measure this change to calculate the amount of applied force.

Manufacturers typically make strain gauges from a thin, electrically conductive foil arranged in a grid pattern.When a load applies pressure, the grid deforms and the resistance changes.

How Strain Gauge Load Cells Work

Strain gauge load cells operate on the precept of converting mechanical force into a measurable electric sign. Here’s a step-by means of-step take a look at the technique:

1. Force Application

The burden cell initiates when someone applies a force to it. This force might be within the form of compression, anxiety, or shear, depending on the sort of load cellular and the software.

2. Deformation of the Load Cell

Conversely, designers pay attention to the pressure in areas where they place the pressure gauges when designing the load cellular structure.

3. Strain Gauge Reaction

As the burden mobile deforms, so do the stress gauges attached to it.especially this trade in resistance is minimal but detectable.

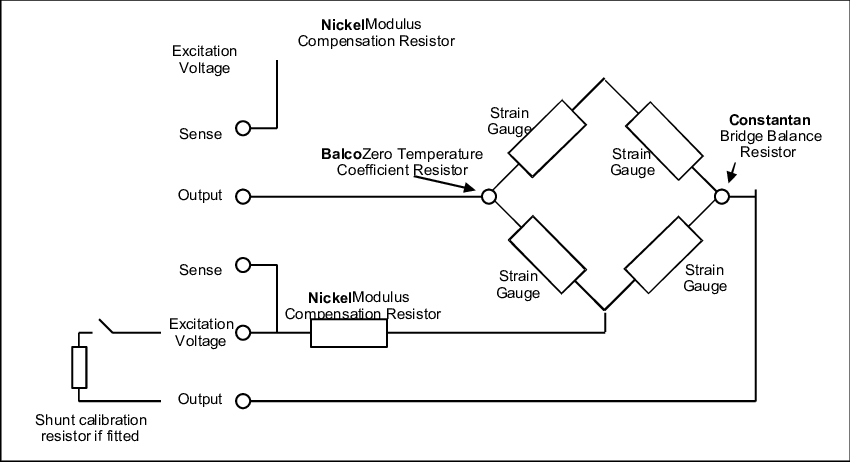

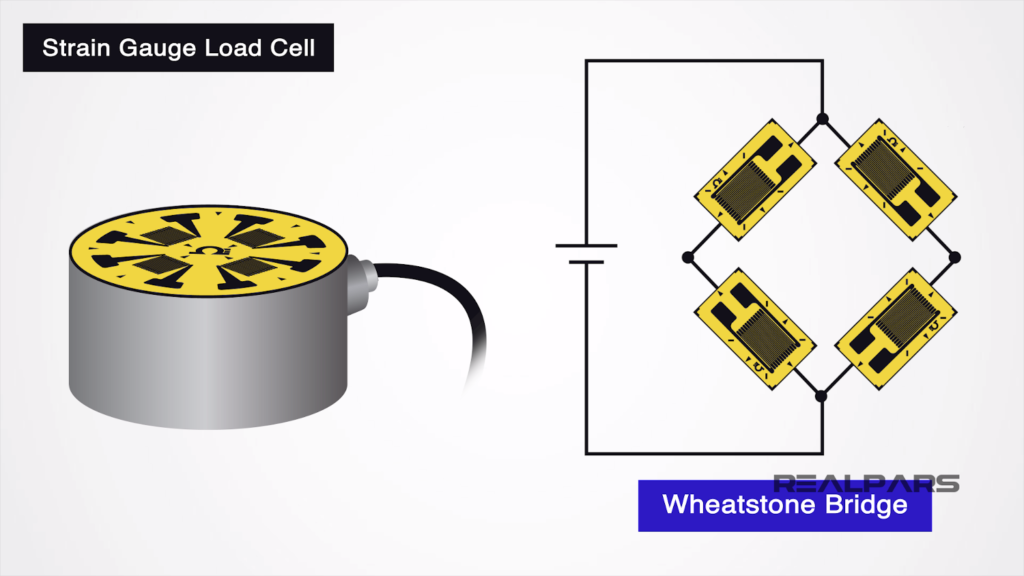

4. Wheatstone Bridge Circuit

To degree the small changes in resistance accurately, strain gauge load cells use a Wheatstone bridge circuit. This circuit is an association of 4 resistors in a diamond shape. In a regular stress gauge load cell, of those resistors are energetic strain gauges (which alternate resistance with strain), next and are fixed resistors.

5. Signal Conversion

When a Strain gauge load cells work is carried out, the Wheatstone bridge turns into unbalanced, developing a differential voltage output. This output is a small analog voltage signal proportional to the weight. The sign is then amplified to make it readable via statistics acquisition structures.

6. Calibration and Output

The amplified sign is calibrated to ensure accuracy. Calibration includes applying acknowledged weights to the burden cellular and adjusting the output to suit the predicted values. finally Once calibrated, the burden cellular can provide correct weight or pressure measurements.

Types of Strain Gauge Load Cells

The most common sorts include:

1. Single-Point Load Cells

Single-point load cells are designed for platform scales and small weighing systems. They can handle hundreds of pounds even if the weight is not centered, which makes them ideal for retail scales and commercial weighing systems.

2. Shear Beam Load Cells

In commercial environments, shear beam load cells typically use to measure shear pressure and find application in floor scales, hopper scales, and process weighing.

3. Bending Beam Load Cells

Bending beam load cells measure the force applied along a beam, causing it to bend. They find use in packages requiring excessive precision, as well as in laboratory balances and medical scales.

4. Compression Load Cells

Compression load cells measure masses that compress the cell. They find applications in areas such as truck scales, tank weighing, and structural testing.

5. Tension Load Cells

Tension load cells measure the pressure pulling the mobile aside. They are used in applications consisting of crane scales, cable anxiety size, and tensile testing.

Advantages of Strain Gauge Load Cells from eTAZ Systems

eTAZ Systems is a leading provider of stress gauge load cells, presenting numerous advantages through their modern designs and advanced technology.

1. High Accuracy and Precision

eTAZ Systems’ load cells are engineered for excessive accuracy and precision. They are able to measuring minute changes in pressure, ensuring reliable and constant readings even in traumatic programs.

2. Robust Construction

The load cells from eTAZ Systems are built to resist harsh environments. Besides They are made from notable materials that offer durability and sturdiness, making them appropriate for commercial and outside packages.

3. Versatility

eTAZ Systems offers a extensive range of strain gauge load cells, catering to various packages. Whether you need load cells for small-scale laboratory measurements or big-scale commercial weighing, instance eTAZ Systems has a solution.

4. Easy Integration

eTAZ Systems designs its load cells for smooth integration into current structures. They provide compatibility with widespread weighing signs, information acquisition structures, and PLCs, simplifying the setup and use procedure.

5. Customization

Understanding that distinct packages have precise requirements, eTAZ Systems offers customization options for his or her load cells. Customers can specify dimensions, capacities, and other parameters to get a tailor-made answer.

Applications of Strain Gauge Load Cells

Strain gauge load cells from eTAZ Systems discover packages across numerous industries due to their versatility and reliability. Here are some key software areas:

1. Industrial Weighing

In business settings, correct weight size is crucial for inventory control, high-quality manipulate, and procedure automation. Strain gauge load cells are utilized in platform scales, hopper scales, and conveyor belt scales to make certain unique weight measurements.

2. Aerospace and Defense

In aerospace and protection, particular force dimension is crucial for trying out and monitoring structural integrity. Strain gauge load cells are used in testing the strength of substances, monitoring load distribution in plane, and testing the performance of protection system.

3. Medical Devices

In the clinical discipline, correct pressure size is vital for ensuring the protection and efficacy of scientific gadgets. Strain gauge load cells are utilized in applications which include surgical contraptions, patient tracking structures, and rehabilitation device.

4. Automotive Industry

The car enterprise relies on strain gauge load cells for numerous checking out and manufacturing processes. They use strain gauge load cells in crash testing, component testing, and monitoring the force applied during assembly processes to ensure safety and quality.

5. Construction

In creation, stress gauge load cells reveal structural loads and ensure protection. They find use in applications such as monitoring the weight on bridges, measuring the pressure on structural beams, and testing the strength of construction materials.

6. Agriculture

In agriculture, accurate weight dimension is crucial for coping with livestock, measuring feed, and tracking crop yields. We use strain gauge load cells in weighing structures for livestock, feed hoppers, and agricultural machinery.

Future Trends in Strain Gauge Load Cell Technology

The subject of stress gauge load cells is always evolving, with improvements in technology riding upgrades in overall performance and new packages. Here are a few destiny developments to watch:

1. Wireless Load Cells

ETAZ Systems is at the vanguard of growing wi-fi Strain gauge load cells work solutions that offer the identical degree of accuracy and reliability as their stressed opposite numbers.

2. Miniaturization

As era advances, there is a fashion in the direction of miniaturization of load cells. Greater compact and transportable gadgets can utilize smaller load cells without compromising accuracy. Besides This trend is especially applicable for scientific devices and transportable business device.

3. Smart Load Cells

Integration of clever generation into load cells is an rising fashion. Smart load cells can provide actual-time information, self-diagnose problems, and combine with IoT structures for better monitoring and control. moreover ETAZ Systems is exploring methods to comprise clever era into their load cells to offer extra superior and user-friendly solutions.

4. Enhanced Materials

Research into new materials and production techniques is main to the improvement of load cells with advanced performance characteristics. Enhanced substances can provide higher resistance to environmental factors, multiplied sturdiness, and better accuracy.

5. Energy Harvesting

Energy harvesting generation lets in load cells to generate energy from the mechanical electricity carried out to them. This can cause self-powered load cells that require less preservation and have an extended operational life.

Conclusion

Strain gauge load cells are an important device in many industries, imparting accurate and reliable force measurements. ETAZ Systems sticks out inside the marketplace with its wonderful, strong, and versatile load cellular solutions. By knowledge the standards of the way pressure gauge load cells work, their packages, and the destiny developments in the field, industries can higher respect the value and capability of these critical components.

ETAZ Systems continues to innovate and lead in the subject of stress gauge load cells, making sure that their customers acquire the pleasant feasible answers for his or her weighing and pressure size wishes. With a commitment to excellent, precision, and purchaser satisfaction, especially eTAZ Systems stays a depended on call in Strain gauge load cells work technology.