A pressure gauge load mobile is essential in diverse business programs, assisting diploma and show the burden or strain completed to a system.

They understand how to paint those devices Firstly, which is vital for ensuring correct and reliable measurements.

This weblog submission will delve into the working principle of stress gauge load cells, their key additives, differing types, programs, benefits, obstacles, and destiny tendencies in the generation by eTAZsystems .

What is a Strain Gauge Load Cell?

An innovative transducer designed to convert the strain exerted upon it into a digital signal is a stress gauge load cellular at its center. Secondly, This capability allows for unique weight or strain dimension in numerous settings. The coronary coronary heart of its operation lies within the stress gauge, a finely tuned sensor that detects minute modifications in resistance due to the fact the weight cellular deforms underneath stress.

The applied pressure directly causes this deformation, enabling the stress gauge to effectively translate physical pressure into an electrical signal by subsequently altering electric resistance.

This manner is foundational to the functionality of strain gauge load cells, Additionally, presenting the essential information desired for duties ranging from simple weight length to complicated business strategies requiring meticulous pressure control.

The Working Principle of Strain Gauge Load Cells

Its response to carried-out forces is at the coronary coronary heart of a pressure gauge load cell’s operation. These forces cause the cellular to deform, a physical change that alters the electrical resistance of the stress gauge—a sensitive element adhered to the mobile.

This crucial type of resistance directly correlates with the exertion of strain.

The precept hinges on the connection between deformation and resistance alternate, Moreover, a exactly measurable dynamic. Electrical indicators from those resistance changes bypass through a sign conditioner, remodeling them into virtual statistics representing the perfect stress or weight implemented. This conversion procedure is speedy and correct, ensuring the strain gauge load cellular can offer instantaneous and unique readings important for diverse applications. Furthermore, This direct conversion of physical deformation into electric powered-powered signals lets in the ones gadgets to offer unheard-of accuracy in pressure and weight length obligations.

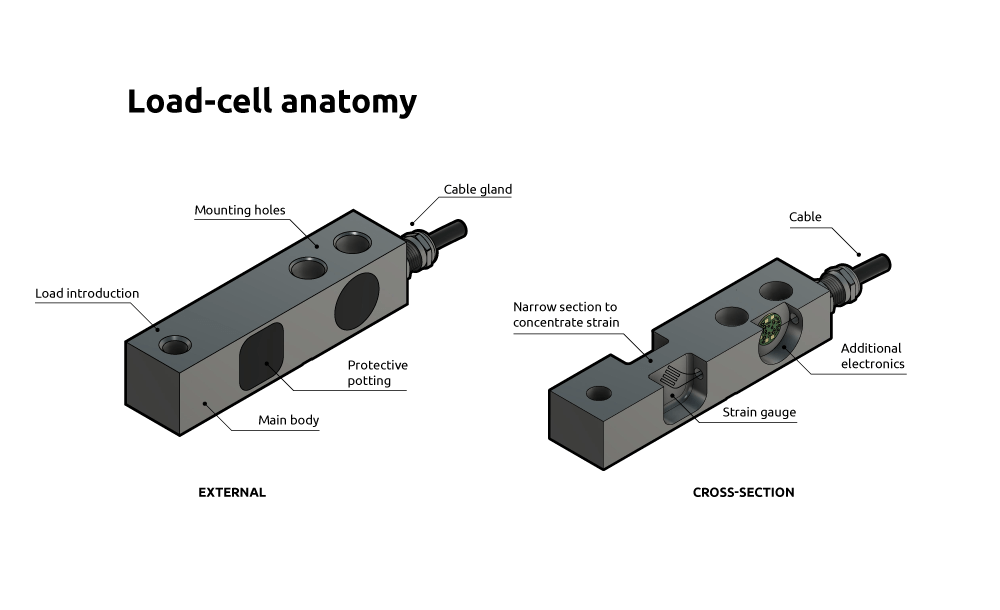

Critical Components of a Strain Gauge Load Cell

The number one components of a strain gauge load cell are:

The strain gauge itself.

The indicator is affixed to the backing cloth.

A shielding enclosure that safeguards the whole assembly.

The pressure gauge, frequently made from a sensitive steel foil sample, serves because of the crucial sensing detail, responding to minute deformations with changes in electric-powered resistance. Carefully determine the backing fabric for its mechanical properties, ensuring it accurately supports the pressure gauge while providing the necessary elasticity and strength to measure pressure or weight effectively. Typically, make this backing from steel or aluminum for its durability and ability to withstand the physical stresses encountered during operation. Surrounding those additives, the protective housing shields the sensitive internals from environmental dangers like moisture, temperature extremes, and physical impacts, making sure the load mobile can characteristic reliably in several conditions without interference or damage.

Types of Strain Gauge Load Cells and Their Applications

Strain gauge load cells are labeled into severa types, every designed to excel, mainly in applications. For example, the bending beam load cell is suitable for precision measurements in platform and hopper scales due to its sensitivity and accuracy in converting finished pressure into a readable electric powered output. Shear beam load cells, excellent through their robustness, are fine for agency environments in conjunction with tank and silo weighing, wherein they carry out under conditions of excessive functionality and lateral masses. S-type load cells, named for his or her shape, offer versatility for anxiety and compression measurements, making them a favored choice for substances checking out and crane scales. Another superb kind includes the compression load mobile, drastically utilized in truck scales and heavy-responsibility weighing programs due to its excessive load potential and resistance to environmental conditions. Each kind’s unique layout developments make sure maximum exceptional overall performance

Advantages and Limitations of Strain Gauge Load Cells

Strain gauge load cells are well-known for their precision and flexibility, making them important for lots packages of many sizes. One in their standout benefits is the immoderate degree of accuracy they’ll obtain, which is vital for industries that demand precise weight and strain measurements. Their reliability is a key benefit, as they constantly provide correct readings over the years, making sure facts integrity in important packages. Moreover, these load cells are built to ultimate, supplying designs that might face harsh environmental conditions and mechanical stresses; this is critical for his or her use in business settings.

Despite those advantages, stress gauge load cells have disturbing conditions. Their typical performance may be caused by the treasured resources of outside elements and temperature fluctuations, necessitating extra additives or calibration to keep accuracy. Electrical noise is every other problem which can have an effect on the precision of measurements, requiring cautious protecting and grounding strategies. Additionally, whilst the ones load cells are designed to go through great strain, exceeding their mechanical limits can reason permanent harm, underscoring the importance of choosing the ideal load cellular for the application. These troubles spotlight the need to stability the blessings and capability barriers even as enforcing pressure gauge load cell generation.

Strain Gauge Load Cell Working Principle

A stress gauge load cell is essential in various commercial enterprise programs, helping diploma and display the weight or strain finished to a machine. Understanding how those gadgets are painted is crucial to make certain accurate and reliable measurements are taken. This blog submission will delve into the operating principle of stress gauge load cells, their key additives, different types, packages, benefits, obstacles, and destiny traits inside the generation.

What is a Strain Gauge Load Cell?

At its middle, a stress gauge load cell is an advanced transducer designed to transform the pressure exerted upon it into a digital signal. This capability allows for specific weight or stress size in numerous settings. The coronary heart of its operation lies within the stress gauge, a finely tuned sensor that detects minute adjustments in resistance due to the fact the burden cell deforms beneath strain. This deformation is a right away end result of the stress applied, and the subsequent alteration in electric resistance permits the stress gauge to efficiently translate bodily pressure into an electrical sign. This procedure is foundational to the functionality of stress gauge load cells, supplying the critical information wanted for responsibilities starting from simple weight size to complicated commercial strategies requiring meticulous pressure control.

Working Principle of Strain Gauge Load Cells

Its reaction to carried-out forces is at the coronary coronary heart of a strain gauge load mobile’s operation. These forces reason the cell to deform, a bodily trade that alters the electric resistance of the strain gauge—a touchy detail adhered to the mobile. This vital version of resistance correlates directly with the exerted stress. The precept hinges on the relationship between deformation and resistance alternate, a exactly measurable dynamic. Electrical indicators from those resistance modifications skip thru a sign conditioner, transforming them into virtual statistics representing the suitable stress or weight implemented. This conversion process is speedy and correct, ensuring the pressure gauge load mobile can provide immediately and precise readings essential for various programs. This direct conversion of physical deformation into electric-powered alerts permits those devices to offer unheard-of accuracy in stress and weight length obligations.

Critical Components of a Strain Gauge Load Cell

The primary components of a pressure gauge load cell are:

The pressure gauge itself.

The backing cloth has the indicator affixed to it.

A defensive enclosure that safeguards the entire assembly.

The stress gauge, often crafted from a touchy steel foil sample, serves because of the crucial sensing element, responding to minute deformations with adjustments in electric-powered resistance. The text in Active Voice is as follows: “Experts carefully determine the backing fabric for its mechanical properties, ensuring it can accurately support the pressure gauge while providing the necessary elasticity and strength to measure pressure or weight accurately. Usually, manufacturers make this backing from metal or aluminum, chosen for its durability and ability to withstand the physical stresses encountered during operation. Surrounding those components, the protective housing shields the sensitive internals from environmental risks like moisture, temperature extremes, and physical influences, ensuring the weight cell can function reliably in several conditions with out interference or harm.

Types of Strain Gauge Load Cells and Their Applications

Strain gauge load cells are classified into severa kinds, every designed to excel, mainly in packages. For example, the bending beam load cellular is appropriate for precision measurements in platform and hopper scales because of its sensitivity and accuracy in converting completed pressure into a readable electric output. Shear beam load cells, exquisite thru their robustness, are best for agency environments along with tank and silo weighing, in which they perform under situations of immoderate functionality and lateral masses. S-kind load cells, named for his or her form, provide versatility for tension and compression measurements, making them a favored preference for substances testing and crane scales. Another first rate type consists of the compression load cellular, notably utilized in truck scales and heavy-duty weighing packages because of its immoderate load capacity and resistance to environmental conditions.

Limitations of Strain Gauge Load Cells

Strain gauge load cells are well-known for their precision and versatility, making them necessary for plenty programs of many sizes. One of their standout advantages is the excessive level of accuracy they’ll acquire, that’s vital for industries that demand precise weight and strain measurements. Their reliability is a key advantage, as they continuously offer correct readings over time, making sure information integrity in important programs. Moreover, we construct those load cells to withstand ultimate conditions, providing designs that can endure harsh environmental situations and mechanical stresses; this is vital for their use in industrial settings.

Despite those benefits, stress gauge load cells have worrying conditions. Their ordinary performance may be due to the treasured sources of outside elements and temperature fluctuations, necessitating extra additives or calibration to keep accuracy. Electrical noise is some other trouble that can affect the precision of measurements, requiring cautious protective and grounding strategies.

The significance of selecting the appropriate load cell for the application is held because surpassing their mechanical limits can cause permanent damage, despite the load cells being designed to withstand considerable stress.

These problems spotlight the want to stability the blessings and capability barriers while imposing stress gauge load mobile era.

Future Trends in Strain Gauge Load Cell Technology

Pressure gauge load mobile technology is evolving to embody the virtual transformation sweeping through numerous sectors.

IoT (Internet of Things) and AI (Artificial Intelligence) innovations are poised to redefine how data is captured, processed, and interpreted.

With the aggregate of wi-fi connectivity, the following era of pressure gauge load cells will offer seamless facts transmission, facilitating some distance-flung monitoring and manipulate of measurement structures. This bounce earlier not most effective successfully complements operational overall performance however also minimizes the want for manual oversight, allowing real-time modifications and predictive safety based totally on unique statistics analytics. We anticipate that advancements in our understanding of materials’ technology will empower us to produce even more resilient and sensitive stress gauges, thereby expanding their applicability to environments and pressures that we previously considered burdensome.

FAQS

Frequently Asked Questions About Strain Gauge Load Cells

Q: How do temperature adjustments affect a stress gauge load cell?

A: Furthermore, Temperature fluctuations can affect the accuracy of stress gauge load cells by converting the electric resistance of the stress gauge. Manufacturers usually encompass temperature repayment mechanisms to mitigate those consequences and preserve size accuracy.

Q: Can one stress gauge load cells withstand harsh environments?

Yes, designers create pressure gauge load cells with protecting enclosures to withstand harsh environmental conditions, such as moisture, dirt, and excessive temperatures, making them suitable for use in numerous enterprise settings.

Q: What is the difference between anxiety and compression measurements in stress gauge load cells?

A: Tension measurements involve forces that pull the burden mobile apart, and compression measurements comprise forces that together push the load mobile’s additives. In addition specific sorts of pressure gauge load cells, like the S-kind, can correctly duplicate every anxiety and compression force.

Q: How regularly do strain gauge load cells need calibrated?

A: The calibration frequency for stress gauge load cells relies upon the precision required for the software software and the on foot conditions. Experts generally recommend regular calibration to ensure ongoing accuracy, as the best software language length varies based on usage intensity and environmental factors.