In modern rapid-paced industrial global, precision size is vital for ensuring the efficiency and accuracy of diverse methods. One era that has been gaining recognition for its excessive level of precision is the six axis load cellular. His superior era is revolutionizing the way industries across the globe carry out load and force measurements. In this blog post, we will discover the efficiency and effectiveness of six axis load cells, specially in eTAZ systems structures.

Understanding the Six Axis Load Cell Technology

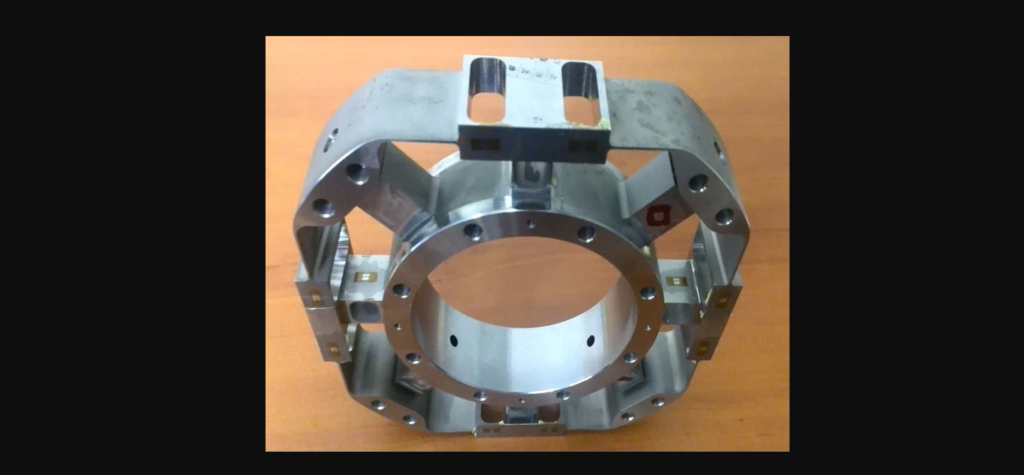

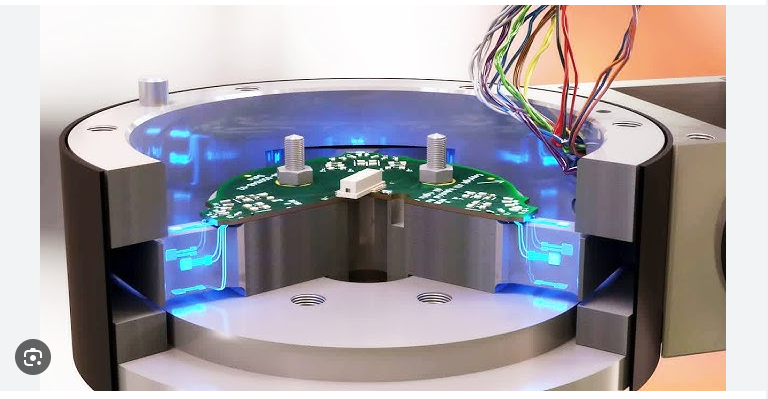

At the coronary heart of six axis load cellular generation lies an imaginitive mechanism able to taking pictures forces and torques across three perpendicular axes (X, Y, and Z) and round the ones axes to hit upon pitch, yaw, and roll. This multifaceted technique to dimension is what units these gadgets apart, supplying a comprehensive view of the stresses and lines exerted on an item. Central to the operation of these load cells are pressure gauges, sophisticated components that convert mechanical deformation into electrical signals. These alerts, proportional to the forces applied, undergo specific calibration approaches to make sure accuracy.

The layout and implementation of these stress gauges inside the load cell’s shape allow the detection of subtle adjustments in force and moment, making the six axis load cell an vital tool for applications requiring nuanced measurements.It can concurrently report statistics across multiple axes, allowing for an in-depth analysis of complex force interactions. This characteristic is paramount in fields such as robotics and aerospace engineering, where the dynamics of movement and load are complicated.

This technology not best underscores the significance of precision in pressure measurement however also highlights the evolution of load mobile layout to house increasingly more state-of-the-art industrial and studies packages. The six axis load mobile, via its distinctive pressure and second taking pictures abilties, opens up new possibilities for analyzing and understanding the bodily global.

The Role of Six Axis Load Cells in eTAZ Systems

eTAZ systems, standing for digital Total Artificial Zones, represent the vanguard of manipulate system generation, wherein precision and adaptableness are paramount. At the core of their capability, six axis load cells offer useful facts important for the machine’s operational efficiency. By accurately measuring forces and moments in more than one directions concurrently, these load cells offer a level of insight into mechanical stresses that is unequalled with the aid of traditional size devices.

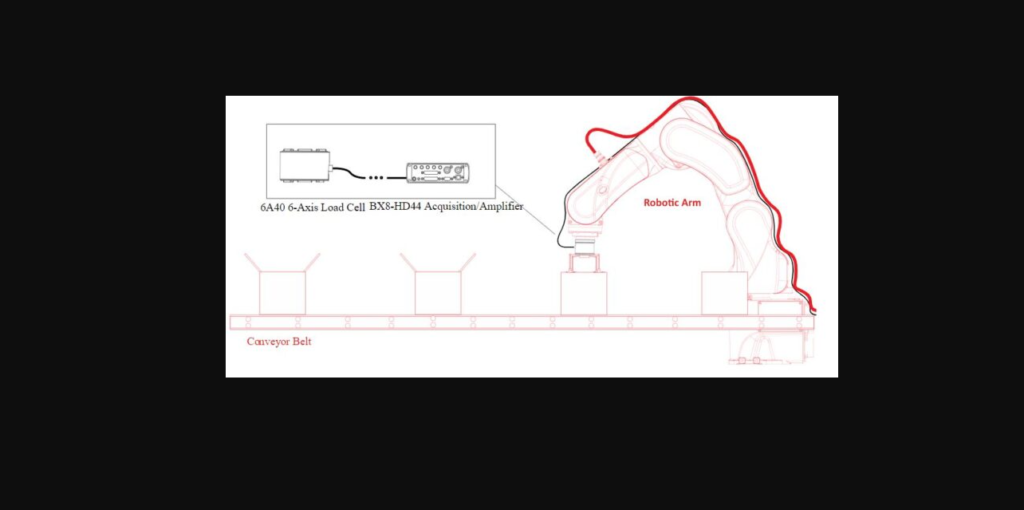

In the realm of eTAZ systems, six axis load cells capture nuanced facts, allowing for finely tuned control and adjustment to meet the machine’s needs. For instance, in robotic automation, the precision supplied via these load cells allows for adjustments in real-time, making sure that robotic movements are both accurate and green. Similarly, in advanced manufacturing approaches, the capacity to screen and alter based on complete load information can result in significant enhancements in product excellent and production efficiency.

Furthermore, the mixing of six axis load cells into eTAZ systems structures facilitates advanced diagnostics and predictive protection abilities. By constantly monitoring the forces acting at the machine, operators can pick out capability issues before they lead to failure, lowering downtime and maintenance expenses. This element of predictive preservation, empowered by way of the exact insights from six axis load cells, underscores their essential position inside the effectiveness and sustainability of eTAZ systems structures.

Key Applications of Six Axis Load Cells in Industry

Six axis load cells have determined essential packages across numerous commercial landscapes, gambling pivotal roles in improving the precision and efficiency of operations. In the aerospace region, those sophisticated sensors are integral to the rigorous checking out regimes implemented to plane structures, simulating a number of pressure situations that additives can also come upon in flight. The automobile enterprise leverages six axis load cells for dynamic vehicle testing and within the essential evaluations all through crash simulations, where know-how the multidimensional forces concerned can lead to widespread improvements in protection designs. Manufacturing centers include those load cells to streamline fine manipulate procedures and optimize production strains, thereby ensuring products meet stringent standards even as reducing waste and improving throughput. In the area of robotics, six axis load cells are fundamental for the development and operation of robot structures, supplying the necessary comments to ensure moves are unique, safe, and green.

Advantages of Using Six Axis Load Cells in Precision Measurement

The unprecedented accuracy and comprehensive records series skills of six axis load cells cause them to necessary in precision measurement tasks. Their potential to determine minute changes in pressure and torque across more than one axes translates to relatively dependable facts, crucial for making essential adjustments in both commercial and studies settings. This degree of detail complements choice-making procedures, facilitating refinements that drastically raise device performance and product satisfactory. Furthermore, the flexibility of those load cells extends their utility throughout a vast spectrum of packages, from robotic engineering to aerospace testing, showcasing their adaptability to numerous environments and requirements. Durability is another key feature, as these load cells are designed to withstand the trials of stressful commercial environments, ensuring long-term reliability and reducing the need for frequent replacements.

Installation and Maintenance Tips for Six Axis Load Cells

Ensuring that your six axis load cell operates at height overall performance involves meticulous interest at some stage in the set up segment and a devoted method to ongoing maintenance. Initial setup should strictly adhere to the hints provided by way of the producer. Precise calibration is fundamental proper from the begin, because it ensures that the weight cell can deliver accurate and dependable measurements. Employing a qualified technician for the set up and calibration system can prevent capability inaccuracies and operational problems.

To maintain the load cell in optimal condition, establish a regular schedule. Clean the load cell regularly using non-abrasive materials to remove any debris that could affect its sensitivity and accuracy. Conduct visual inspections frequently. These inspections can identify early signs of wear or damage, such as cracks or corrosion on the load cell body or abnormalities in the stress gauge attachments.

If you detect any irregularities in measurement accuracy or sign output, you may need to recalibrate to restore optimal functionality.

Lastly, you have to monitor the surrounding environment of the load cell.”

Future Trends in Six Axis Load Cell Technology

As dimension technology evolves, six-axis load cell technology is poised for groundbreaking improvements. A great improvement at the horizon is the mixing of Internet of Things (IoT) skills. This enhancement will no longer best facilitate seamless information transmission but also enable real-time analytics and manage, providing unparalleled levels of insight and performance. Additionally, the power toward miniaturization and increased sensitivity will see those load cells becoming even more compact, without sacrificing performance. This fashion is in all likelihood to extend their applicability, making them perfect for use in areas where conventional load cells can not suit or operate successfully. Innovations in substances technology are also predicted to play a critical function, with the adoption of novel alloys and composites that offer advanced sturdiness and reliability beneath intense situations.

FAQS

Q: Can six axis load cells be utilised in any industry?

A: Absolutely. Six axis load cells are highly flexible and have been efficiently incorporated across plenty of industries, such as aerospace, automobile, manufacturing, and robotics. Their ability to offer precise measurements in six levels of freedom makes them useful in any setting that needs excessive-precision pressure and moment measurement.

Q: How do six axis load cells differ from conventional load cells?

A: Unlike conventional load cells, which usually degree pressure along an unmarried axis, six axis load cells can degree forces and moments in 3 dimensions. This method they are able to discover forces and torques alongside the X, Y, and Z axes, in addition to pitch, yaw, and roll, presenting a greater comprehensive analysis of the forces acting on an item.

Q: What renovation do six axis load cells require?

A: Six axis load cells require normal cleansing, visible inspections, and purposeful checking out to maintain their accuracy and durability. It’s also crucial to keep them calibrated and defend them from excessive environmental conditions to make certain reliable overall performance.

Q: Are there any rising tendencies in six axis load cellular generation?

A: Emerging trends include the integration of IoT talents for actual-time analytics and management, miniaturisation for use in tighter areas, and improvements in materials for more desirable durability. These tendencies promise to amplify the applications and efficiency of six axis load cells even similarly.