When it involves measuring weight and pressure correctly, the S-Type load cellular running precept plays a vital role in various industries. From making sure product excellent in production approaches to tracking weight distribution in automobiles, S-Type load cells are versatile devices which can be important for lots packages. In this weblog post, we will discover the running principle of S-Type load cells, their role in eTAZ systems, key applications, installation pointers, and maintenance insights.

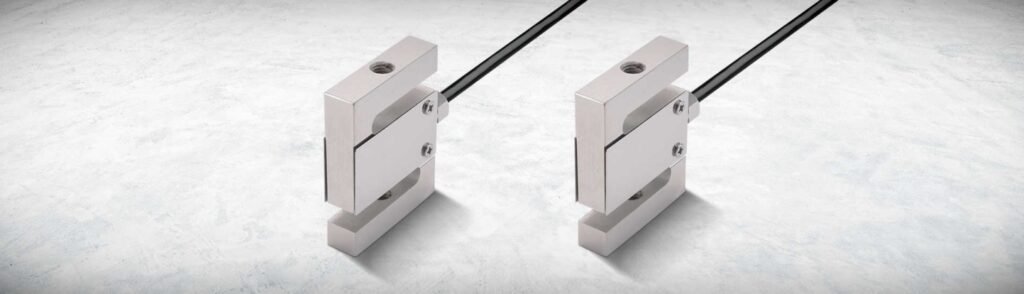

Unveiling the S-Type Load Cell

S-Type load cells, characterized with the aid of their distinctive ‘S’ form, stand out as pivotal force transduction devices. “Our team meticulously engineers these units to gauge both tensile and compressive forces with amazing precision. Integral to their design are two mounting holes situated at every stop, facilitating a honest installation technique throughout diverse settings. This structural design no longer only contributes to their ease of integration into numerous structures however also underscores their adaptability and person-friendliness.

The essence of S-Type load cell’ operation lies in their ability to transform mechanical pressure right into a quantifiable electric output. The strategic placement of pressure gauges in the mobile enables the execution of this process. Upon application of pressure, those strain gauges undergo deformation, a phenomenon that ends in a measurable alteration of their electric resistance. This alternate is immediately proportional to the force exerted, enabling the best calculation of weight or implemented force.

Recognized for his or her first rate accuracy and dependability, S-Type load cells have grow to be a cornerstone in sectors that prioritize exactitude in force and weight dimension. Their design guarantees not only regular performance, but also amplifies their reliability, making them essential in scenarios where precision is not just desired but crucial.

How It Works

At the core of an S-Type load cellular’s capability is the deformation of pressure gauges in response to applied forces. These pressure gauges, essential components of the load cellular, are touchy factors that trade their electrical resistance when stretched or compressed. This transformation happens because of the burden mobile’s design, which allows it to flex below the weight or force exerted upon it. The deformation of the strain gauge alters its electrical resistance in a way that is at once proportional to the force implemented, enabling the conversion of a physical pressure into an electrical signal.

This electrical signal is a reflection of the quantity of force or weight applied to the burden cellular. Through a process of sign processing, this electrical output is then translated into a virtual studying, effectively quantifying the force in understandable terms. It’s this procedure that underpins the S-Type load mobile’s recognition for precision and sensitivity, bearing in mind surprisingly accurate measurements in quite a number packages.

Given this mechanism, it is obvious why S-Type load cells are favored for duties wherein genuine measurements are paramount. Their capacity to reliably convert physical pressure into quantifiable electrical indicators makes them imperative in eventualities that demand utmost accuracy, which include in pleasant manipulate or load distribution analysis.

The Role of S-Type Load Cells in eTAZ Systems

In the elaborate community of eTAZ systems, S-Type load cells are instrumental in delivering actual-time, unique measurements of weight and pressure. These systems, which often contain a mix of superior sensors and analytical components, depend heavily on the accuracy and reliability of S-Type load cells to feature optimally. Their function is particularly important in packages wherein tracking and controlling weight and force are important for operational protection and efficiency. For example, in automobile weight distribution analysis, S-Type load cells provide critical facts that informs adjustments to enhance overall performance and safety. Similarly, in production settings, they may be key to automating tactics that depend on unique weight measurements, including the filling of packing containers or the software of forces in meeting operations.

The integration of S-Type load cells into eTAZ structures exemplifies a synergy among mechanical engineering and virtual generation, permitting state-of-the-art tracking and control abilities. These cells aren’t simply passive components; they actively contribute to the device’s intelligence by means of providing statistics that is crucial for decision-making procedures, whether or not it’s in real-time changes or in long-time period strategic planning. This makes them necessary in the seamless operation of eTAZ structures throughout a vast spectrum of industries, from automating manufacturing traces to enhancing the reliability of safety-vital systems in aerospace and car sectors.

Key Applications and Industries Benefited

The versatility and precision of S-Type load cells cause them to valuable throughout a spectrum of sectors. In the world of car engineering, they play a important function in assessing automobile weight distribution, a aspect essential for each overall performance optimization and safety enhancement. Aerospace packages gain similarly, with load cells ensuring the balance and integrity of aircraft by using offering correct weight measurements. The manufacturing area relies heavily on these devices for first-class manage purposes; they’re instrumental in automating strategies that require precise weight measurements, including filling operations or the controlled application of pressure at some point of assembly. Additionally, within the healthcare industry, S-Type load cells facilitate the correct monitoring of patient weight, a essential component in each analysis and remedy, inclusive of the right dosing of drugs based totally on weight-sensitive protocols.

Installation Tips and Best Practices

For a successful set up of S-Type load cells, precision and attention to element are paramount. Start by way of cautiously selecting the mounting place to make certain it is appropriate for the load cell’s operation, taking into consideration the route and nature of the force to be measured. The mounting surface ought to be solid and flat to avoid any undue stress or pressure at the load cell, which could cause erroneous readings or premature failure.

Mounting hardware have to be selected with care; use extraordinary bolts and ensure they’re tightened to the producer’s specs to keep the integrity of the weight mobile. It’s additionally crucial to rent the ideal alignment strategies, as misalignment can significantly effect the accuracy of measurements. Employ spacers or mounting plates if necessary to achieve most reliable alignment.

Environmental issues can not be unnoticed. Protect the burden cellular from harsh situations via considering shielding enclosures if the operating surroundings is prone to moisture, dirt, or severe temperatures. To prevent damage from environmental exposure or electromagnetic interference, secure and shield the electric connections.

Lastly, after installation, a thorough calibration is crucial to validate the accuracy of the load cell. This step guarantees that the load cell’s output corresponds appropriately to the carried out pressure. “Encourage regularly scheduled recalibrations as part of the renovation recurring to sustain size accuracy over the lifestyles of the load cell.” Following those suggestions will not most effective enlarge the lifespan of the S-Type load cellular but also make certain its dependable performance in precision-important packages.

Overcoming Challenges and Maintenance Insights

Ensuring the long-term reliability of S-Type load cells hinges on proactive upkeep and addressing operational demanding situations efficaciously. One of the number one issues is the potential for overloading, which not simplest jeopardizes the cellular’s integrity however also its dimension accuracy. Implementing recurring checks and balances, including monitoring machine indicators for load potential breaches, can mitigate this risk. Additionally, the surroundings in which the burden cell operates can pose challenges, from fluctuating temperatures to publicity to corrosive substances, all of which can effect overall performance and toughness. Establishing a regular upkeep time table that includes cleaning, inspection for corrosion or physical damage, and verification of electrical connections facilitates maintain the weight cellular’s situation. Calibration is another vital aspect; periodic recalibration ensures that the weight cellular maintains to offer precise measurements, compensating for any glide in sensitivity over time.

Conclusion

In conclusion, the S-Type load cell emerges as an quintessential tool in the realm of precise pressure and weight measurement throughout a multitude of industries. Its working precept, which efficiently converts bodily force into quantifiable electrical alerts, underscores its critical position in enhancing operational efficiency, protection, and first-class control. The adaptability of S-Type load cells to integrate seamlessly into eTAZ structures in addition exemplifies their value in cutting-edge technological packages, from manufacturing to healthcare. By following fine practices for installation, calibration, and renovation, customers can maximize the reliability and sturdiness of those devices. Embracing the S-Type load cell for its precision, versatility, and durability will undoubtedly preserve to power innovation and excellence in diverse fields. As we have explored the running standards, packages, and care for those vital gadgets, it is clean that the S-Type load cellular stands as a cornerstone in the pursuit of dimension accuracy and operational excellence.