When it comes to measuring the level of materials in tanks or silos, radar stage transmitters are critical devices. These devices use radar technology to accurately decide the extent of beverages, solids, or slurry within a container. In this complete manual, we can delve into the numerous kinds of radar stage transmitters within the marketplace today and speak about their specific capabilities and applications. Let’s discover the world of radar-level transmitter kinds and how they can gain numerous industries.

Introduction to Radar Level Transmitters

Radar degree transmitters emit high-frequency radar waves toward the substance being measured.” These waves travel via the tank or silo surroundings, and upon hitting the floor of the fabric, they mirror back in the direction of the transmitter. The device then measures the time these radar pulses take to journey to the surface and back. This length is pivotal in calculating the gap from the transmitter to the floor of the fabric, which, in flip, determines the extent of the substance.Radar level transmitters play a critical role in industries requiring precise monitoring of material levels because this method allows notably accurate measurements. Their ability to characterise effectively below an extensive range of environmental situations, including people with high strain, varying temperatures, or volatile substances, highlights their versatility and indispensability in industrial operations.

Understanding eTAZ Systems in Radar Technology

The eTAZ gadget represents an enormous jump in the radar-level transmitter era, incorporating advanced tracking algorithms that set it apart from traditional radar structures. These algorithms allow the eTAZ systems gadget to supply surprisingly specific stage measurements, which stay dependable even below the maximum difficult conditions, along with extreme stress variations and temperature fluctuations. The heart of the eTAZ gadget’s capability lies in its sophisticated software, which can correctly interpret radar indicators, efficiently distinguishing between the genuine surface level of the material and any false signals resulting from environmental elements. This precision is essential in industries where the accuracy of level measurements without delay influences operational performance and protection. With its advanced technology, the eTAZ system presents a solution that complements the reliability of radar stage dimension, providing a robust alternative for applications with the highest ranges of accuracy and reliability.

The Various Types of Radar Level Transmitters

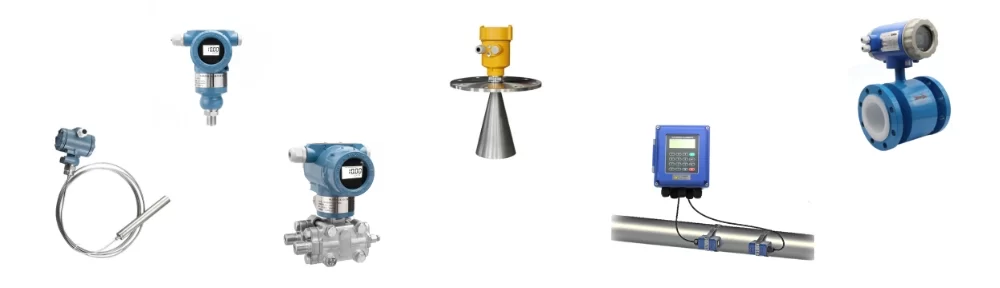

Exploring the variety of radar degree transmitters unveils alternatives tailor-made to distinct enterprise desires and size-demanding situations. These transmitters are categorised into guided wave radar (GWR), pulse radar, and frequency-modulated non-stop wave (FMCW) radar transmitters. GWR transmitters excel in unique liquid degree measurements, which are particularly useful in vessels with internal obstructions or various geometries, by sending radar alerts alongside a probe that comes in contact with the medium. Pulse radar variants, emitting quick bursts of radar waves, are adept at handling solids and slurry materials, providing flexibility in demanding conditions, including dust or severe temperatures. FMCW radar transmitters, distinguishing themselves through the emission of a continuous wave that varies in frequency, offer superior accuracy and resolution in liquid and vital programs by reading the frequency shift of again indicators.

Non-Contact vs. Contact Radar Level Transmitters

Understanding the difference between non-touch and contact sorts in radar degree transmitters is paramount for selecting the most suitable device for a given software. Non-touch radar level transmitters, which include devices like frequency-modulated continuous wave (FMCW) transmitters, operate by sending radar signals closer to the cloth’s floor from above without making any physical touch. Ideally, situations in which the cloth’s homes or the environment — together with excessive temperature or corrosive substances — preclude direct touch, suit this class ideally. On the flip side, contact radar degree transmitters, exemplified via guided wave radar (GWR) models, contain a probe extending into the measured fabric, making direct contact. These transmitters are mainly effective in coping with complicated situations, along with excessive-viscosity liquids or materials showing the widespread variance of their dielectric homes. The preference among non-touch and speak-to types hinges on different factors, inclusive of the nature of the fabric.

Critical Considerations for Choosing the Right Radar Level Transmitter

Selecting the perfect radar stage transmitter requires nuanced information on several pivotal elements past mere operational requirements. The nature of the substance being monitored—liquid, stable, or slurry—dictates the best type of radar-level transmitter. Equally essential is the environment the transmitter will perform in, such as temperature extremes, vapours or dirt, and capacity obstructions inside the tank. The geometry of the container itself, whether or not it’s a slim silo or a broad tank, can have an impact on the choice between guided wave and non-contact radar transmitters. Additionally, the necessity for accuracy cannot be overstated; cheerful packages can also demand extremely particular measurements, necessitating advanced models like the eTAZ structures. Moreover, the mixing talents of the transmitter with present management structures and its compliance with enterprise requirements must also be considered to ensure a continuing and green operation.

Innovative Applications of Radar Level Transmitters in Industry

Radar stage transmitters have revolutionised operations throughout various industries, with particular demanding situations and requirements. In water remedy and management, these devices are instrumental in tracking reservoir tiers and ensuring top-rated water distribution. Their real-time capability to deliver particular measurements allows operators to maintain balance in water delivery structures, which is critical for municipal and business applications.

In the agricultural sector, radar stage transmitters are hired to oversee the stages of grains and other bulk materials in silos, facilitating green garage control and helping to prevent spoilage or overflow. This software is treasured explicitly throughout harvest season while garage capacities are maximised.

Energy technology enterprises also benefit substantially from radar-degree transmitter generation. Here, you may monitor the stages of coal in feed structures or the water levels in cooling towers. Such programs are critical for maintaining a continuous and green strength era and ensuring operations’ safety.

Further, in environmental monitoring, radar level transmitters play a vital role in monitoring water stages in rivers and dams, contributing to flood warning structures and mitigating the impact of capacity flooding occasions. This functionality underscores the broader societal benefits that those superior dimension equipment provide, extending beyond business applications to serve network protection and environmental conservation efforts.

The Future of Radar Level Measurement Technology

The trajectory of radar degree-size technology is ready for colossal innovation, pushed by the evolving wishes of diverse industries.

We expect future iterations to further refine the accuracy and dependability of these structures, as well as simplify the complexities associated with their deployment.

A pivotal location of development lies within digital connectivity, in which the combination of IoT (Internet of Things) abilities will enable real-time records trade and analytics, enhancing decision-making tactics.

Improved state-of-the-art diagnostics equipment will couple with this, enabling the prediction of capability troubles earlier than they affect operations. This will increase the overall efficiency of the structures they monitor.

Additionally, the power closer to miniaturisation and the reduction of strength consumption will play an essential role in making radar stage transmitters more sustainable and less complicated to install, even inside the most confined areas.

Conclusion

In summing up our exploration of radar-level transmitter types, it’s clear that those devices play a pivotal role throughout a vast spectrum of industries, presenting particular and reliable measurements essential for operational performance and protection. From the revolutionary eTAZ structures that carry high accuracy to tough environments to the difference among contact and non-touch transmitters catering to particular application desires, the selection and application of those contraptions require considering different factors. The destiny of the radar stage dimension era promises even more incredible advancements, with virtual connectivity, sustainability, and more suitable diagnostics poised to raise operational skills