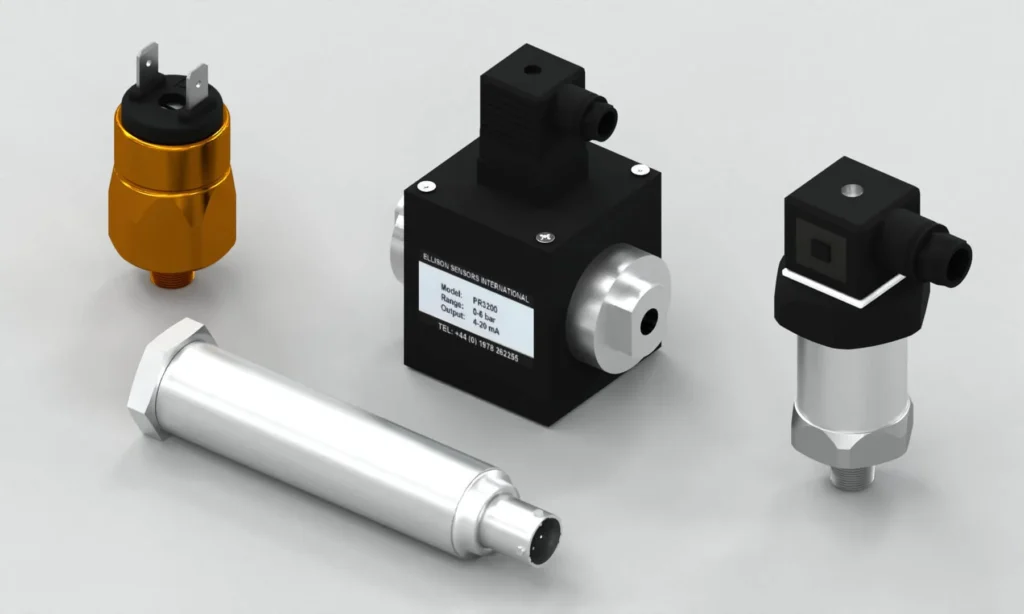

In the modern era, the pressure transducer is an important factor that powers many structures and devices. One such gadget that closely relies on pressure transducers is the eTAZ machine. Additionally this innovative era has revolutionised diverse industries, imparting unheard-of efficiency and accuracy. Moreover Let’s delve deeper into the world of strain transducers and explore their pivotal function in eTAZ systems structures.

Unveiling the eTAZ System: A Comprehensive Overview

The Electronic Throttle Actuation and Control System, the eTAZ system, stands at the forefront of throttle management technology. It integrates superior electronics to manage throttle positions in diverse machines, from cars to business gadgets. The eTAZ device guarantees particular throttle manipulation, optimising machinery performance and fuel intake by employing a sophisticated community of sensors and actuators. The heart of its operation is the pressure transducer, a device essential for translating mechanical pressures into actionable electrical indicators. Furthermore this translation is pivotal for the actual-time modifications essential for throttle management, facilitating a seamless interaction between mechanical components and digital control devices. Also The TAZ machine’s reliance on such correct and responsive components underscores its potential to decorate efficiency and performance across diverse applications.

The Pressure Transducer: Heart of the eTAZ System

The strain transducer is relevant to the eTAZ machine’s unheard-of functionality and instrumental in bridging the distance between mechanical motion and digital management. This crucial device meticulously displays video displays and units of the gadget’s inner pressures, translating physical force into a virtual signal that the system’s electronic management unit can interpret and act upon. Similarly Its position is not merely passive; the pressure transducer actively informs the management unit, allowing immediate adjustments to the throttle’s function, thereby ensuring the most desirable performance and efficiency. This non-stop feedback loop enables the eTAZ gadget to achieve high precision in throttle control. The complete device’s efficacy hinges on the pressure transducer’s reliability and accuracy, showcasing its significance not as a supplementary component but because it is the linchpin of the eTAZ architecture.

Deciphering the Working Principle of Pressure Transducers

At the core of stress transducer generation lies an advanced procedure that permits those gadgets to appropriately translate bodily pressures into electronic alerts. This mechanism is based on the deformation of pressure gauges or the electric reaction of piezoelectric materials to carry out stress. When strain exerts force on the transducer, those sensitive elements undergo a structural alternate, stretching or compressing within the case of stress gauges or producing a voltage in piezoelectric materials. This alteration leads to a measurable change in electric resistance or produces a voltage output directly proportional to the strain implemented.

This generated sign is sometimes best in its raw shape; it calls for amplification to turn out to be interpretable through electronic control gadgets like the ones in eTAZ systems. The amplified sign uniquely represents the strain ranges in the machine, considering dynamic tracking and adjustments through the management unit. This manner ensures that changes in pressure are as they should be contemplated inside the machine’s response, facilitating the correct management over throttle mechanisms feature of the eTAZ era. The interaction between strain transducers and the electronic manipulation unit is seamless, supplying actual-time facts critical for retaining the most efficient performance in applications where precision is paramount. Through this elegant translation of physical force into digital records, strain transducers are the foundational element, allowing sophisticated manipulation and automation in modern-day technological systems.

The Significance of Pressure Transducers in eTAZ Systems

The critical role of strain transducers inside eTAZ systems must be balanced. These devices are instrumental in converting the mechanical pressures omnipresent inside the system’s operation into virtual indicators that the digital control unit can correctly interpret. This conversion is crucial for the precise modulation of the throttle, which impacts the gadget’s performance. The inherent ability of strain transducers to offer real-time, accurate records guarantees that eTAZ systems can immediately alter throttle positioning, which is crucial for optimising gas intake and equipment operation.

Furthermore, stress transducers’ sturdiness and reliability contribute significantly to eTAZ structures’ robustness. Given the disturbing environments in which those structures often function—ranging from high-velocity car applications to important aerospace mechanisms—the exceptional and consistent statistics provided by stress transducers are important. This guarantees that eTAZ systems preserve their precision and responsiveness over time, reinforcing their value in high-performance packages.

Consequently, integrating pressure transducers into eTAZ structures exemplifies a perfect symbiosis between mechanical engineering and electronic management. This harmonious integration enhances the abilities of traditional throttle control structures, marking a leap ahead in the quest for extra efficiency, precision, and reliability in numerous technological programs. Through the lens of pressure transducer technology, eTAZ structures stand as a testament to the profound impact of this component on the evolution of throttle management answers.

Real-world applications of eTAZ Systems Powered with the aid of Pressure Transducers

The implementation of eTAZ structures, empowered by the precision of strain transducers, has heralded a brand new generation throughout a couple of industries, showcasing the versatility and effect of this generation. In the international automobile, those structures have emerged as a cornerstone for boosting throttle responsiveness, supplying drivers with a more excellent dynamic and gasoline-green riding. This results in stepped-forward car performance and significantly reduces carbon emissions, aligning with worldwide sustainability dreams. The aerospace enterprise, too, benefits notably from the mixing of eTAZ systems. Here, the exacting demands for engine manipulation and safety are met with unheard-of precision, thanks to the actual-time statistics and modifications made possible by strain transducers. This guarantees the plane can perform optimally below diverse conditions, improving performance and protection. Additionally, in production, eTAZ structures have introduced a brand new stage of control and reliability in equipment operation, optimising production approaches and reducing downtime.

Future Prospects: Innovations in Pressure Transducer Technology

The horizon for stress transducer technology is brimming with ability, driven via breakthroughs in nanotechnology, wireless verbal exchange, and records analytics. These emerging fields promise to introduce a new era of stress transducers that aren’t the best smaller but also notably extra electricity-green and capable of transmitting facts wirelessly, supplying more flexibility in their integration with eTAZ structures and past. As the Internet of Things (IoT) continues to make a more significant impact across industries, the role of pressure transducers in connected gadgets and intelligent structures is about to become even more critical. Likewise the potential to monitor and manipulate stress in real-time faraway places will permit unparalleled stages of automation and performance. Furthermore, improvements in cloth science are anticipated to yield transducers that could face extreme conditions—including high temperatures and corrosive environments—without compromising accuracy or lifespan.

Conclusion

As we’ve navigated the intricacies of pressure transducers and their critical position in eTAZ systems, it is obtrusive that those gadgets are more than simply components; they are the linchpins of modern automation and control technologies. Their capability to correctly translate mechanical pressures into electronic alerts has improved the precision and performance of throttle control and paved the way for advancements throughout diverse industries, from cars to aerospace. Looking in advance, the continued evolution of the pressure transducer era, with its promise of more integration with AI and IoT, indicates an exciting future where their utility will further revolutionise how we technique automation and manipulate complicated structures. As we prepare for those technological advancements, pressure transducers’ importance in driving innovation and efficiency in eTAZ systems and beyond stays undeniably profound.