Have you ever puzzled how a pressure gauge load mobile works? In this weblog post, we will wreck down the functionality of this important piece of era. From expertise the fundamentals to exploring the components and principle of operation, we are able to delve into the internal workings of pressure gauge load cells. Additionally, we are able to discuss the different types of pressure gauge load cells, their applications, and the position of eTAZ systems in enhancing their performance. Finally, we are able to touch on troubleshooting commonplace issues and study destiny traits in stress gauge load cell era. So, let’s get began on unraveling the mystery of ways a pressure gauge load cell works.

Understanding the Basics of Strain Gauge Load Cells

Strain gauge load cells are instrumental in precisely measuring forces or weights exerted on objects. Central to their operation is the idea that a fabric’s electrical resistance varies when subjected to stretching or compression. This phenomenon is the foundation of how those gadgets ascertain the magnitude of force carried out. Crucial throughout multiple sectors, which includes manufacturing, construction, and car, the correct statistics provided with the aid of these load cells aids in preserving satisfactory and safety standards. Their huge-ranging utility underscores the importance of expertise the fundamental mechanics behind pressure gauge load cells and their position in various commercial methods. This foundational knowledge is vital for leveraging the entire abilties of these devices and appreciating the technological advancements that keep to decorate their precision and reliability.

The Components That Make Up a Strain Gauge Load Cell

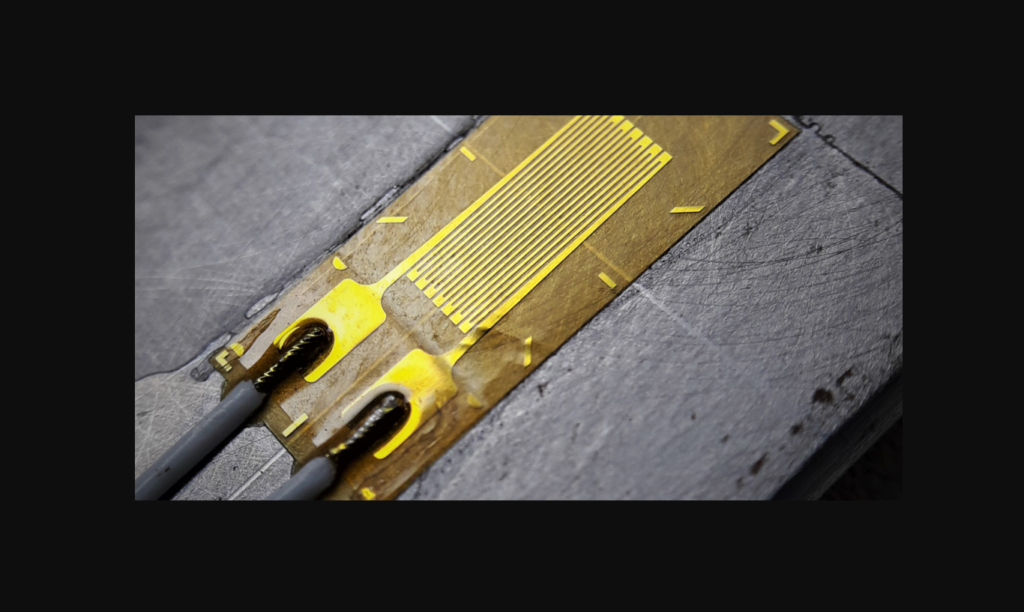

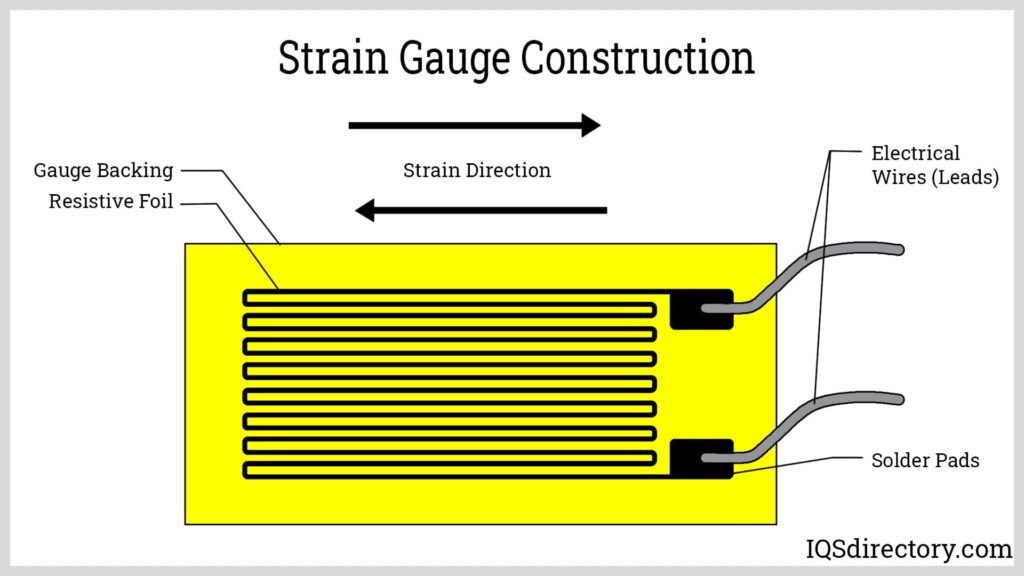

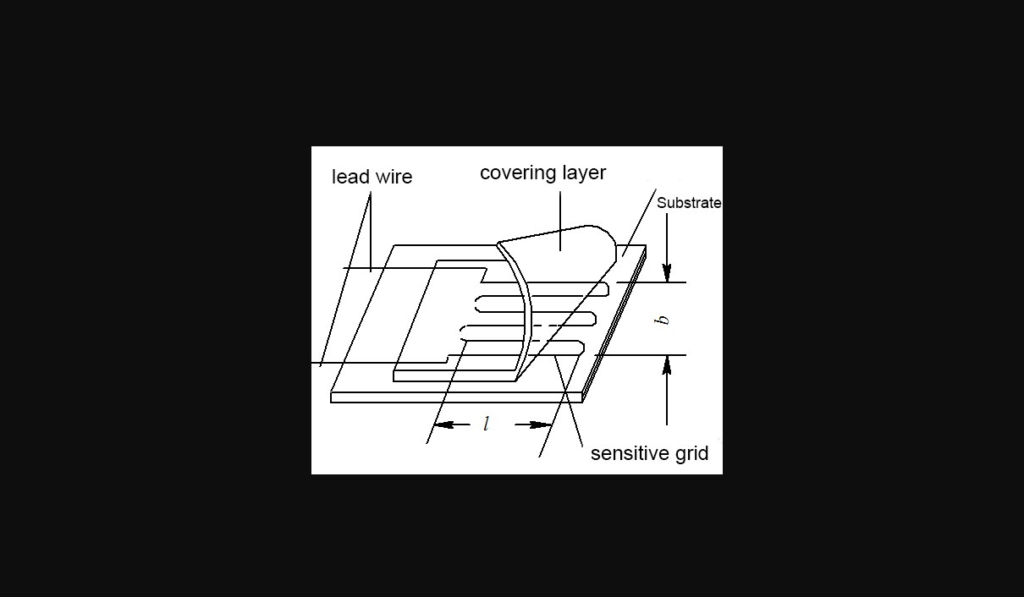

At the center of a pressure gauge load cellular’s layout are numerous vital additives that work in tandem to measure force or weight appropriately. The most crucial of these components are the pressure gauges themselves. These are finely tuned sensors crafted from conductive foil or metal that reply to minute modifications in bodily strain by using altering their electric resistance. Encased inside the load cell, the pressure gauges are meticulously connected to a bendy backing, permitting them to locate the slightest deformations in the cellular shape when force is carried out.

Surrounding the strain gauges is the burden cell housing, a strong structure crafted to face up to harsh environments and guard the touchy components inside. This housing is normally crafted from materials like aluminum or stainless-steel, chosen for their durability and resistance to environmental elements like moisture and temperature fluctuations.

Finally, vital to the function of the stress gauge load cell are its electrical connections. These connections are cautiously engineered to transmit the facts accumulated with the aid of the stress gauges to an outside dimension tool or device. They consist of wires and connectors that should hold excessive degrees of conductivity and reliability to make sure accurate sign transmission.

Together, those components form the backbone of a stress gauge load cellular, allowing it to convert mechanical force into a measurable electrical output. Through their complex design and interaction, they allow the weight cellular to perform its vital role in numerous packages, from industrial weighing systems to precision engineering tasks.

The Principle of Operation: Strain to Electrical Signal Conversion

At the coronary heart of a strain gauge load cell’s capability is the transformative method that converts mechanical pressure into a quantifiable electrical signal. This operation plays a vital role in translating the physical deformation of the mobile, due to the implemented pressure, into statistics that we can appropriately measure and analyze. When pressure exerts onto the burden cell, it induces a deformation within the cellular shape. This physical exchange prompts the stress gauges—connected inside the load cell—to either stretch or compress, correlating immediately with the value of the force carried out.

This alteration in the bodily kingdom of the stress gauges ends in a proportional trade of their electric resistance. The precept that underpins this phenomenon is the pressure gauge’s inherent sensitivity to pressure, which, whilst experienced, modifies its electrical conductivity. In this era, engineers engineer strain gauge load cells in several awesome designs to cater to a wide array of applications, reflecting the flexibility and adaptableness.

The load mobile harnesses this resistance exchange, translating it into an electrical sign thru a manner of signal conditioning. This signal is proportional to the pressure implemented, taking into consideration a unique dimension of the load or pressure. This conversion from a mechanical alteration to an electrical output is fundamental to the weight cell’s operation, permitting the correct interpretation of forces that would otherwise be tough to quantify. Through this sophisticated mechanism, pressure gauge load cells provide crucial records throughout a huge range of programs, from commercial manufacturing to structural checking out, showcasing their versatility and vital function in modern era.

Types of Strain Gauge Load Cells and Their Applications

In this era, engineers engineer strain gauge load cells in several awesome designs to cater to a wide array of applications, reflecting the flexibility and adaptableness. Among the different types, bending beam, shear beam, and S-kind load cells are especially noteworthy for their specialised makes use of. Bending beam load cells, which exhibit sensitivity and precision, predominantly serve in commercial weighing structures and small-scale packages where accuracy is paramount. Alternatively, shear beam load cells excel in environments subjected to lateral forces and typically find application in bulk handling and industrial scales due to their robustness and ability to address multi-directional forces. Load cells, named for their shape as S-kind, exhibit flexibility and commonly serve in tension and compression measurements, making them suitable for a broad spectrum of tasks from crane scales to force measurement testing systems.

The Role of eTAZ Systems in Enhancing Strain Gauge Load Cell Performance

eTAZ structures drastically augment the functionality and efficacy of strain gauge work load cells through integrating current features that address commonplace size challenges. With the inclusion of temperature repayment capabilities, those structures are adept at adjusting measurements to account for thermal consequences, ensuring steady overall performance across quite a number environmental situations. Digital sign processing (DSP) technology, some other hallmark of eTAZ structures, offers state-of-the-art filtering and noise discount strategies. This leads to more suitable signal readability and precision, making an allowance for greater accurate pressure size readings. Additionally, the implementation of wi-fi connectivity in eTAZ systems introduces a degree of comfort and versatility previously not possible. This function enables easy data collection and monitoring from remote locations, removing the need for cumbersome wiring and enabling extra streamlined system integration.

Troubleshooting Common Issues with Strain Gauge Load Cells

Strain gauge load cells, while notably dependable in shooting specific measurements of force or weight, aren’t proof against experiencing technical demanding situations. These difficulties may also manifest as waft, signal interference, or inaccuracies due to overload situations. Numerous troubleshooting steps can endorse mitigating those troubles. First and primary, undertaking ordinary calibration tests is critical. This procedure enables in verifying that the load cell’s output remains accurate through the years, accounting for any ability float that may arise. It’s also important to inspect all electrical connections meticulously. Loose or corroded connections can lead to intermittent indicators or increased electric noise, significantly affecting the statistics’s reliability. Addressing this includes tightening connections and likely replacing any damaged cables or connectors to make certain most useful overall performance.

Furthermore, ensuring that the load mobile is successfully installed in accordance with the manufacturer’s guidelines plays a crucial role in its functionality. Incorrect set up can lead to choppy loading, causing premature wear or distortion of the cellular, ultimately impacting its accuracy. Regular maintenance, including visible inspections for signs and symptoms of damage or damage, is equally crucial. This proactive approach aids in figuring out capacity issues earlier than they escalate into more massive issues, thereby preserving the pressure gauge load mobile’s accuracy and extending its service life.

Future Trends in Strain Gauge Load Cell Technology

The landscape of strain gauge load mobile era is about to adapt dramatically, driven by means of the seamless integration of emerging technologies. Innovations in nanotechnology are at the horizon, promising to miniaturize load cells with out compromising on their accuracy, making them greater flexible for programs requiring compact solutions. We expect enhanced cloth sciences to produce even more resilient strain gauge work , capable of operating in severe conditions while maintaining precision. The incorporation of clever generation will allow for real-time information analysis and selection-making at once on the factor of dimension, streamlining approaches and increasing productiveness. Moreover, the development of strength-harvesting techniques will allow those load cells to grow to be extra self-sufficient, decreasing the need for external strength sources and further increasing their software variety.

FAQS

Frequently requested questions about strain gauge work load cells regularly middle around their functionality, application, and troubleshooting. Common inquiries include:

1. What are the main applications of pressure gauge load cells?**

Numerous sectors utilize strain gauge load cells, including business weighing structures, manufacturing, production, automotive, and research, for unique pressure and weight measurement purposes.

2. How frequently have to a pressure gauge load cellular be calibrated?

Usually, it’s advisable to calibrate these devices at least annually or after any event that could affect their accuracy. The calibration frequency depends on the intensity of usage and the operational surroundings.

Three. Can stress gauge load cells paintings in harsh environments?**

Yes, with right housing materials like chrome steel and technological enhancements together with the ones provided by way of eTAZ structures, those load cells can reliably characteristic in difficult conditions.

4. What ought to I do if my strain gauge work load mobile isn’t offering correct readings?**

First, test all electrical connections for tightness and integrity. Next, please confirm that you have effectively mounted the load mobile and ensured it is not overloaded or damaged. If issues persist, recalibration or consulting with the manufacturer may be vital.

These questions encapsulate some of the key concerns and issues users have concerning the powerful use and renovation of strain gauge work load cells.