When it comes to ensuring the accuracy and functionality of load cells, using a multimeter is a treasured device. In this weblog publish, we will explore the step-by means of-step process of the way to check a load cellular the usage of a multimeter. eTAZ systems By following those guidelines, you can efficaciously troubleshoot and hold your load mobile for most effective overall performance. Let’s dive into the sector of multimeters and load cells to apprehend how to test load cellular via multimeter.

Understanding Load Cells and Their Importance

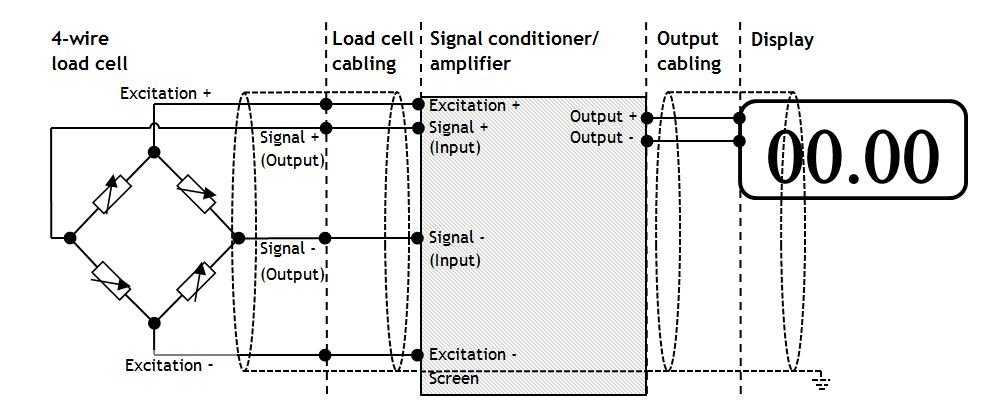

Load cells function vital additives in measuring systems, remodeling mechanical force into electrical indicators. These gadgets play a pivotal position across a variety of sectors, together with production, logistics, and engineering, via supplying precise measurements of weight, force, or strain. In those applications, load cells play a vital role, ensuring that procedures are completed appropriately, successfully, and thoroughly. For example, in the manufacturing industry, load cells monitor fabric weights to maintain quality control, while in construction, they measure the load-bearing capacity of structures to guarantee compliance with safety standards.The reliability of load cells immediately affect,

Preparing to Check a Load Cell

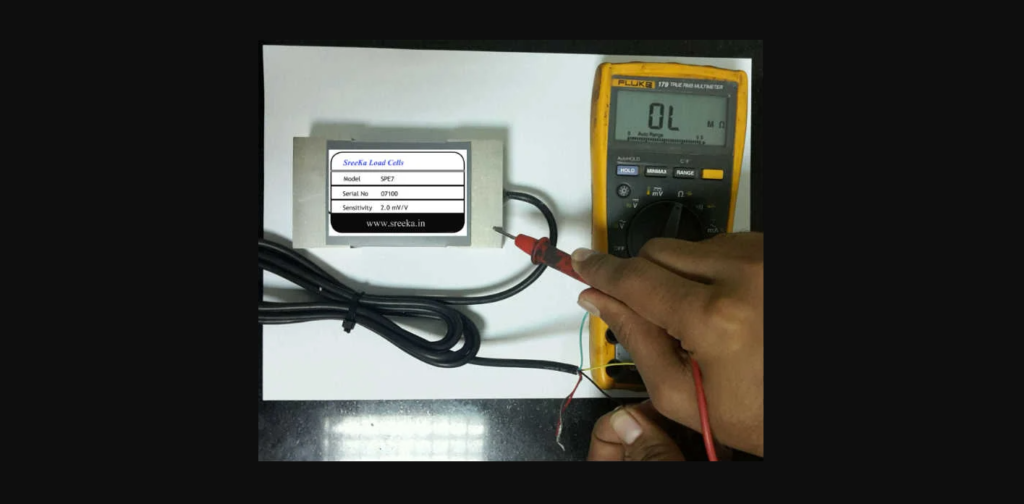

Before embarking at the process of analyzing a load cellular with a multimeter, some initial steps are vital to ensure a clean and correct checking out procedure. First and most important, disconnect the burden cell from any electric strength source to prevent capability risks or inaccuracies for the duration of the checking out phase. It is likewise crucial to alleviate the load cellular of any mechanical pressure or stress it is able to be below, as this can influence the test results. After taking those precautions, acquire the important equipment for the challenge: a dependable multimeter, well-suited test leads, and the weight cell’s datasheet .The datasheet is especially crucial as it consists of specs a good way to manual you in setting the multimeter effectively and decoding the results accurately.

Identifying Multimeter Settings for Load Cell Testing

To appropriately measure a load mobile’s situation using a multimeter, start by using switching the multimeter to the ohmmeter or resistance size setting. This is important as load cells function by using altering resistance beneath pressure, and examining those resistance adjustments can display a great deal about their health. The specific resistance variety you choose on your multimeter will depend upon the weight cellular in question. For guidance on the precise range, consult the burden cell’s datasheet where the nominal resistance values are precise. This instruction allows for a extra precise and tailored trying out approach, making sure that the readings to procure are each relevant and indicative of the burden cell’s performance.

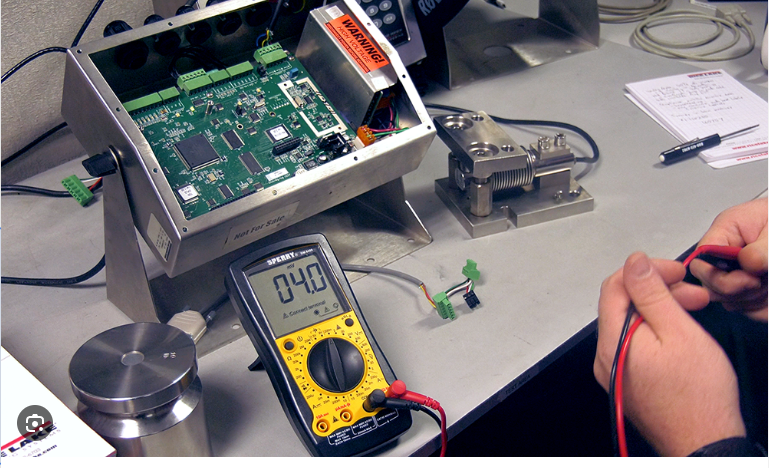

Performing Resistance Checks at the Load Cell

To commence resistance checks at the load cellular, provoke via as it should be attaching the multimeter’s test leads to the specific terminals of the load mobile. This manner requires a methodical technique to make certain that the connection is secure and nicely aligned for accurate measurements. With the multimeter set to the ohmmeter or resistance measurement mode, carefully observe the display for the resistance value. It’s crucial to refer lower back to the load cell’s datasheet for the predicted resistance values beneath regular conditions. Comparing the multimeter analyzing with those predefined values offers insights into the load cell’s health.

A discrepancy among the discovered and predicted resistance values can signal capability troubles. For example, a better than expected resistance may recommend an interruption inside the load cell’s conductive pathway, probable because of inner harm or corrosion. Conversely, a lower resistance ought to indicate a quick circuit within the load cellular’s shape. Such findings necessitate in addition exam to pinpoint the precise purpose and determine the ideal corrective measures. This step is crucial in figuring out early symptoms of damage or failure, bearing in mind timely interventions that may prevent extra serious malfunctions. Engaging in this practice aids in keeping the weight cell’s functionality and reliability, underscoring the significance of meticulous resistance exams as a part of habitual load mobile renovation.

Testing Load Cell Output with a Multimeter

To further verify the functionality of a load mobile, trying out its output signal is a crucial step that includes the usage of a multimeter along with applying a recognized pressure or weight. Begin through connecting the multimeter’s leads to the burden cell’s output terminals, making sure a stable and accurate connection. Next, observe a specific pressure or weight to the weight cell, which have to generate a measurable output within the form of voltage or cutting-edge. Carefully examine the output on the multimeter and evaluate these values to the ones precise in the load cellular’s datasheet. Disparities in the readings may imply discrepancies within the load cellular’s calibration or its universal operational fitness. This manner no longer only validates the resistance measurements formerly performed but also gives a complete evaluate of the burden cell’s capability to appropriately convert mechanical force

Interpreting Results and Troubleshooting

“If you find inconsistencies with predicted benchmarks when reading the resistance or output values, you can undertake a few crucial steps to perceive and rectify the issue. Initially, make sure all connections are stable and not compromised; even a minor disconnection can skew readings substantially. Examine the burden cell and its wiring for any symptoms of wear and tear, harm, or corrosion, as those can disrupt the device’s capability. In conditions wherein bodily harm seems minimal or non-existent, recalibration of the burden cellular might be essential to realign its readings with widespread values. In cases wherein those interventions do not remedy the discrepancies, in search of expert diagnostic services can be the pleasant path of movement. Check a Load Cell this approach allows for an in-depth examination of the weight cell’s internals and its operational integrity, ensuring the detection and addressing of any subtle faults.

Maintaining Your Load Cell for Optimal Performance

To shield the overall performance and toughness of load cells, adopting a regular renovation habitual is paramount. This consists of retaining the weight cell surroundings clean, ensuring it stays free from any materials or particles that could compromise its characteristic. Regularly scheduled preservation not only facilitates in maintaining the bodily situation of the load cell however also aids in early detection of ability problems that could affect its performance.

Engagement in periodic inspections is really helpful. During those inspections, visually test for signs of pressure, wear, or corrosion at the load mobile and its connecting cables. Any anomalies discovered for the duration of those checks ought to be addressed directly to prevent in addition complications. Additionally, verifying the burden mobile’s environment is inside the manufacturer’s certain conditions is essential. Extreme temperatures, humidity, or exposure to corrosive materials can adversely have an effect on the burden cellular’s operation and accuracy.

Another key issue of renovation is adherence to the manufacturer’s calibration schedule. Calibration ensures that the burden cell maintains to function inside its intended accuracy specifications. It compensates for any drifts in measurement that may arise through the years because of regular use or environmental factors. Documentation of calibration and upkeep sports is also useful for tracking the load mobile’s performance history and might offer precious insights for troubleshooting if issues arise.

Implementing these upkeep practices will contribute significantly to the burden mobile’s dependable and accurate overall performance, making it a reliable thing to your size system.

FAQS

Q: Can any multimeter be used to test a load cellular?

A: Yes, maximum multimeters which could degree resistance and voltage/present day can be used to check a load cell. Ensure it has the suitable range settings as in step with the load mobile’s datasheet.

Q: How frequently should a load mobile be examined for accuracy?

A: The frequency of checking out can range primarily based at the load cellular’s utilization intensity and the criticality of its measurements. Check a Load Cell It’s really useful to follow manufacturer tips, but a standard rule is to test at least annually or every time you suspect overall performance issues.

Q: What should I do if the resistance or output values from the burden mobile are not as predicted?

A: Double-test connections and ensure the weight cell is free from bodily damage or corrosion. You may need recalibration or expert diagnostic services if discrepancies persist.

Q: Can environmental factors have an effect on load cell trying out effects?

A: Yes, intense temperatures, humidity, and publicity Check a Load Cell to corrosive materials can affect both the checking out manner and the load cell’s performance. Control the checking out environment or follow the producer’s special conditions.

Q: Is recalibration some thing I can do on my own, or must or not it’s professionally executed?

A: Recalibration usually calls for specialized equipment and know-how Certified professionals usually recommend recalibrating load cells to ensure accuracy and compliance with requirements.