Are you suffering to decide in case your load cellular is functioning efficaciously? One of the most green methods to check a load mobile is by the usage of a multimeter. In this comprehensive manual, we will explore how to test a load cell with a multimeter, particularly specializing in eTAZ systems structures. By following these steps, you can make sure correct measurements and troubleshoot any capacity issues with your load cell.

Understanding Load Cells and Multimeters

Load cells are crucial components in various industries, functioning as devices that convert force into a measurable electric output. This conversion manner is fundamental in applications ranging from weighing scales to cloth checking out gadget. On the opposite side of the spectrum, multimeters serve as imperative equipment for electricians and technicians, presenting the capability to measure a couple of electric residences such as voltage, resistance, and cutting-edge. A firm grasp of each gadgets is essential for effectively diagnosing and keeping the performance of load cells. Load cells generally utilize pressure gauges to measure pressure, and the electrical sign produced is at once associated with the amount of pressure implemented. Multimeters, with their functionality to measure resistance, emerge as helpful whilst verifying the fitness and capability of a load cell’s stress gauges and wiring.

Preparing to Use Your Multimeter with a Load Cell

Before diving into the diagnostic technique, it is vital to collect all of the vital equipment and affirm their functionality. A nicely-maintained multimeter, equipped with clean batteries, is important to this instruction. Equally vital is a solid information of your load mobile’s specifications, so that it will play a pivotal position in appropriately decoding the results of your tests. This level of training isn’t just about having the right gadget however additionally about making sure you have a comprehensive hold close of the load cellular’s traits and necessities. This knowledge will be instrumental with regards to effectively applying your multimeter to diagnose and probable rectify any issues along with your load cell. By diligently getting ready in this manner, you put the degree for a a success trying out process, minimizing the threat of misinterpretation of facts or damage to the system.

Identifying Your Load Cell Type

Before embarking at the trying out journey along with your multimeter, pinpointing the unique sort of load cellular you are running with is paramount. The panorama of load cells is numerous, presenting sorts consisting of stress gauge, hydraulic, and pneumatic. Each type reveals distinct operational mechanics and applications, making the identity step essential for deciding on the proper trying out method. An example of this is strain gauge load cells, which are commonly found in industrial scales. They utilize the deformation of strain gauges to measure weight, converting mechanical pressure into an electrical signal. Hydraulic load cells, then again, degree force thru the alternate in pressure of an enclosed fluid, even as pneumatic load cells use air pressure to gauge force. Understanding those variations is important as it without delay affects the testing methods you will appoint.

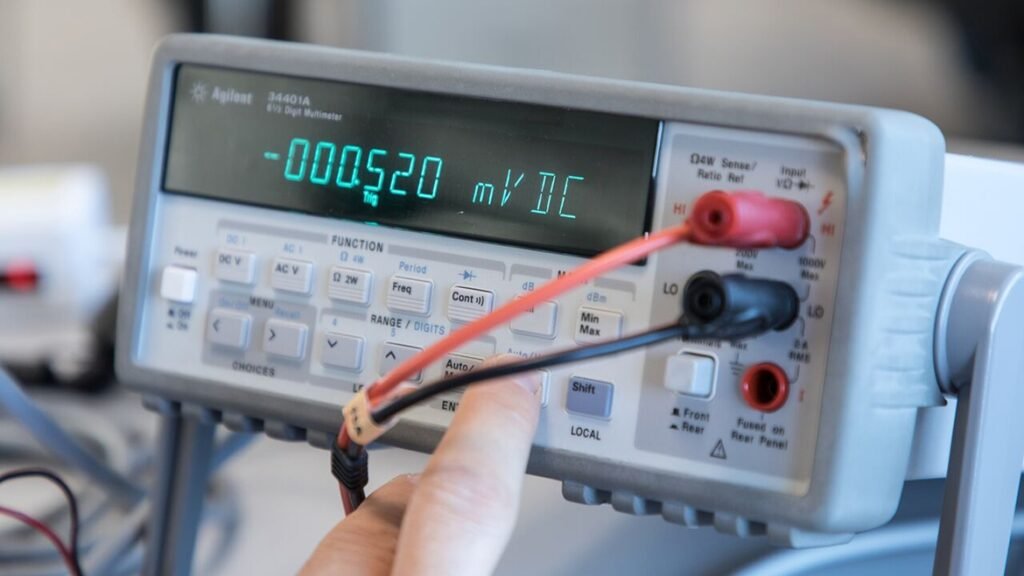

Setting Up Your Multimeter for Load Cell Testing

Before starting load cell testing with your multimeter, ensure that the device is set to measure resistance, typically represented by the Ω symbol on your multimeter. After selecting the suitable placing, connect the multimeter’s ends in the respective terminals on the load cellular. It’s important that these connections are secure and correct according to the load cell’s wiring diagram to avoid faulty readings. Proper setup is pivotal, as it lays the foundation for unique resistance and continuity testing, which are instrumental in evaluating the health and performance of the burden cell. This initial configuration step is easy but essential for effective prognosis and maintenance.

Conducting Resistance and Continuity Tests

After your multimeter is correctly installation to degree resistance, the subsequent important step includes sporting out resistance and continuity tests at the load mobile. Initiating with resistance exams allows you to degree the electrical resistance throughout the load cell’s terminals. This dimension can screen the fitness repute of the burden cell by way of indicating if the resistance tiers fall in the predicted range based totally on the load cell’s specifications. Anomalies in this region may want to sign troubles including degraded additives or mistaken connections. Following the resistance assessments, continuity trying out comes into play, aiming to verify the uninterrupted flow of electricity thru the weight mobile’s circuit.

Measuring Load Cell Output with a Multimeter

To appropriately gauge a load cellular’s output the usage of a multimeter, provoke by means of applying a unique, regarded pressure to the load cellular. This planned movement is vital for generating a measurable reaction from the load cell. With the multimeter set to measure voltage (normally indicated by a V at the device), cautiously connect the device’s ends in the output terminals of the burden mobile. This setup is crucial for taking pictures the electric output generated by means of the carried out force. When the force exerts, the multimeter displays the voltage reading. This analyzing is a right away representation of the weight cell’s reaction to the implemented pressure.

Troubleshooting Common Load Cell Issues

When delving into the area of troubleshooting common load cellular problems, it is critical to technique the assignment methodically. Sign fluctuation or loss, frequently encountered, often stems from faulty wiring or loose connections. Inspecting the cables and connectors for wear and ensuring a snug fit can mitigate these worries. Additionally, environmental factors such as moisture or excessive temperatures can also adversely affect the weight mobile’s overall performance. Make sure to shield the load cell nicely and ensure it operates within its detailed temperature range.Another location of problem is the calibration go with the flow, where the load mobile starts to provide erroneous readings through the years.

Maintaining Your Load Cell for Accurate Measurements

Effective upkeep of your load cellular is pivotal for ensuring its long-time period reliability and precision. Regularly check out the unit for any symptoms of damage or wear, along with the stress gauges and wiring, to preemptively address any issues that could impair its feature. It’s also essential to keep the load cell and its surroundings smooth, preventing the buildup of dirt and particles that might intrude with its operation. Calibration plays a critical position in preservation; performing this method periodically consistent with the manufacturer’s recommendations enables in retaining the accuracy of measurements. Additionally, safeguarding the load cellular towards overloading and impact is important to prevent mechanical harm. Implementing those protection practices helps superior performance, extending the lifestyles span of your load mobile and making sure the consistency of its measurements.

FAQS

Certainly! Here are a few frequently requested questions that may get up while mastering how to test a load cell with a multimeter:

Q: Can any multimeter be used to test a load mobile?

Yes, most multimeters that measure resistance (ohms) and voltage can test a load cell. Make sure to calibrate the multimeter properly for accurate results.

Q: What is the everyday resistance fee range for a functioning load mobile?

A: Resistance values can range widely between different types and models of load cells. It’s crucial to seek advice from the load cellular’s datasheet for the specific resistance variety appropriate for your model.

Q: How frequently have to a load cell be calibrated?

A: Calibration frequency depends on the load cellular’s utilization intensity and the precision necessities of its software. A well-known guideline typically recommends annual calibration, but high-precision packages may also necessitate more frequent checks.

Q: What are the symptoms of a defective load mobile?

A: Signs include inconsistent or erroneous readings, no response to load changes, or fluctuating indicators. If you encounter these issues, thorough trying out and in all likelihood expert servicing can be necessary.

Pingback: What is a Potentiometer Detector and How is it Utilized? -