Have you ever wondered how a load cellular works in physics?

Numerous industries broadly use load cells to measure pressure or weight appropriately.

In this blog submit, we can discover the fundamentals of load cells, the middle principle in the back of their operation, the special types of load cells, the position of physics of their capability, and plenty more. So, permit’s dive into the arena of load cells and uncover the secrets and techniques behind their operation by eTAZsystems.

Understanding the Basics of Load Cells

At the heart of a load mobile is its potential to transduce or convert carried out force right into a measurable electrical output. The load cellular’s structure is vital to this functionality, which commonly consists of a steel frame designed to respond to pressure thru deformation.

These strain gauges attach themselves to the metallic frame and detect the minute adjustments within the form of the metal when pressure is applied.

These strain gauges encompass conductive foil patterns that modify resistance as they stretch or compress alongside the metallic body. This variation in resistance directly correlates with the force exerted on the load cell, enabling particular measurements. The transduction system hinges at the sensitive interplay among mechanical deformation and electric reaction the strain gauges facilitate. This mechanism lets in load cells to provide correct and dependable readings throughout diverse applications.

The Core Principle Behind Load Cell Operation

The basis of a load cell’s capability rests on electrical resistance trade due to mechanical pressure.

The physics of materials and their reaction to forces derive this precept.

When an external pressure or weight acts upon the weight mobile, it induces a deformation in its metal structure. This physical exchange interprets right into a stress in the cloth. Embedded within this structure are stress gauges, that are basically touchy to the pressure, undergoing a resistance exchange as they stretch or compress. This trade in resistance is directly proportional to the amount of pressure implemented, permitting the burden mobile to measure that force exactly. The problematic relationship among mechanical strain and electrical resistance underscores the reliance on fundamental physics standards for the burden mobile’s operation, permitting it to feature as an effective transducer in converting physical forces into easily measurable electric signals.

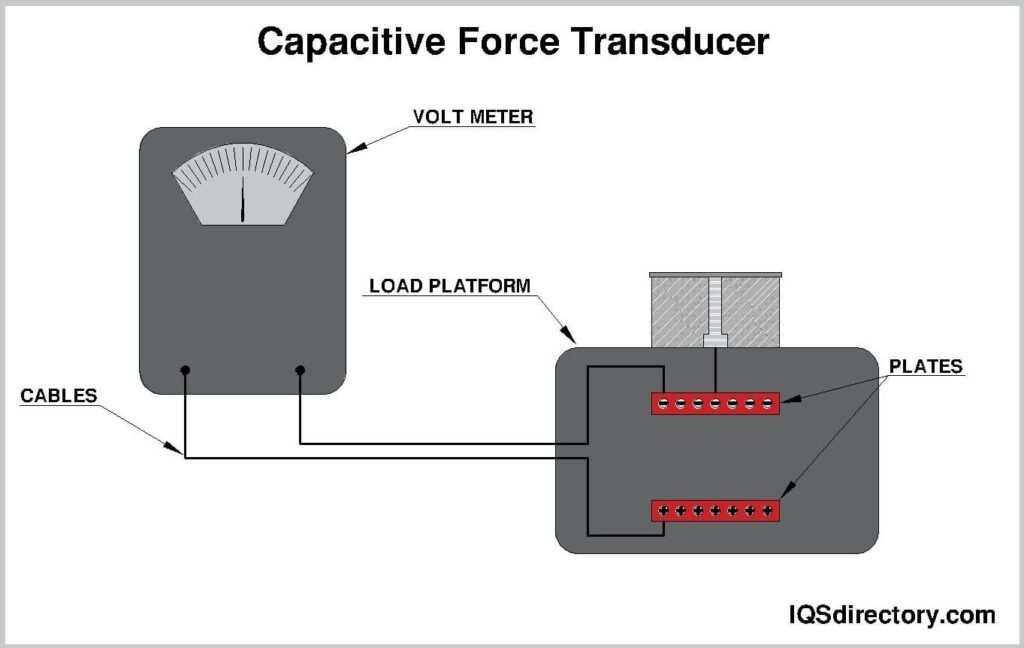

The Various Types of Load Cells and Their Uses

Load cells are classified primarily based on their running mechanism and the utility they may be exceptional acceptable for.

Hydraulic load cells measure the pressure changes within the fluid chamber as force is applied by utilizing a fluid-filled chamber and a piston.

Their durability and resistance to external elements like temperature and vibration make them commonly used in rugged environments.

Pneumatic load cells measure the change in air pressure inside a chamber when applying pressure. Their safety in explosive environments and smooth operation make them valuable, rendering them suitable for the food and pharmaceutical industries.

Strain gauge load cells are the most normal type, using the alternate in electrical resistance of stress gauges bonded to a deformation-susceptible place to measure pressure.

The intricacies of physics are essential to the green functioning of load cells. This includes a harmonious combination of mechanical standards, fabric technological know-how dynamics, and electric engineering theories. At the center of a load cellular’s operation is the precept of piezoresistivity, in which mechanical pressure—because of implemented pressure—interprets into a change in electric resistance.

The physics of semiconductors deeply root this phenomenon, along with the mechanical behavior of materials under load.

Additionally, the standards of elasticity, governing how substances deform and go back to their original form, are vital for expertise and predicting the conduct of the burden mobile’s steel body beneath various forces. Moreover, electric engineering concepts come into play in changing resistance adjustments into measurable electric signals, finishing the transduction system. The amalgamation of these physics-primarily based standards ensures that load cells can supply particular and dependable measurements across many applications.

Step-by-Step: How a Load Cell Converts Force into Electrical Signals

Upon making use of pressure to the burden cell, its metal body undergoes moderate deformation, instigating pressure inside the shape. This stress is immediately sensed via the stress gauges affixed to the weight cell, which might be meticulously designed to respond to such physical modifications. As the stress gauges experience stretching or compression, a amazing exchange in their electrical resistance occurs. This alteration in resistance is indicative of the amount of pressure being implemented. Subsequently, the trade in resistance is transformed into an electrical signal via a conversion method that leverages state-of-the-art electronics. This sign is meticulously calibrated, translating the bodily force into a quantifiable electric output. This series of operations showcases the seamless transition from a mechanical enter to an electrical output, allowing the best quantification of pressure or weight without direct electric input.

Key Factors Influencing Load Cell Accuracy and Performance

Various elements can extensively have an effect on the accuracy and overall performance of load cells. Temperature modifications can result in versions in fabric homes and pressure gauge sensitivity, impacting the precision of measurements.

Ensure to safeguard load cells against overload conditions, which can completely deform the metallic body and strain gauges, rendering the tool less accurate or inoperative.

. Additionally, fabric fatigue, attributable to repeated load cycles, can regulate the mechanical residences of the burden mobile, affecting its lengthy-time period reliability and accuracy. The impact of these factors necessitates cautious consideration and control to preserve the high precision and overall performance requirements required via load mobile applications.

Real-World Applications of Load Cells

From production flora to the medical field, load cells are instrumental in lots of settings. In the commercial zone, they make certain the accuracy of weighing structures, that is vital for batching, filling, and inventory control, thereby streamlining operations and maintaining exceptional manage.

The precision engineering industry relies on load cells for force measurement, enabling the fine-tuning of machinery and testing materials under various loads to ensure their durability and performance.

. In material checking out, those gadgets play a pivotal function in figuring out the power and flexibility of composites, metals, and polymers, offering crucial data for research and development.

In addition, the clinical quarter incorporates load cells into gadgets such as patient lifting structures and advanced weighing scales, ensuring patient safety and assisting in accurate dosage formulations.

FAQS

Q: How does a load cell paintings?

A: A load cellular converts a mechanical pressure into an electrical signal.

When the weight cell applies force, it slightly deforms its shape. Pressure gauges connected to the cell detect this deformation, causing a change in electrical resistance.

The sensor converts the applied force into an electrical signal for measurement and analysis, with the change in resistance directly proportional to the force.

Q: Can load cells measure force in any route?

A.Most load cells measure force in a selected direction, but multi-axis load cells can simultaneously measure forces and torques in more than one direction. The sort of load mobile used relies upon at the unique software requirements.

Q: Are load cells suffering from temperature?

A: Yes, temperature adjustments can impact the accuracy of load cells. Temperature variations can purpose substances to make bigger or contract, affecting the resistance of the stress gauges. Many load cells have temperature repayment functions to mitigate those effects and maintain accuracy.

Q: How lengthy do load cells last?

A: A load cellular’s lifespan can range depending on its production, utilization, and environment. Properly maintained load cells in mild working situations can remaining for many years. However, exposure to harsh situations or overload can substantially reduce their operational life.