Compression load cells are essential tools in various industries for measuring force and weight accurately. However, the game has changed with the introduction of compression load cells with displays. This innovation provides real-time data monitoring and improved efficiency, making it a game-changer for many applications. In this blog post, we will explore the benefits and key features of compression load cells with displays, focusing on the eTAZsystems model.

Understanding the Basics of Compression Load Cells

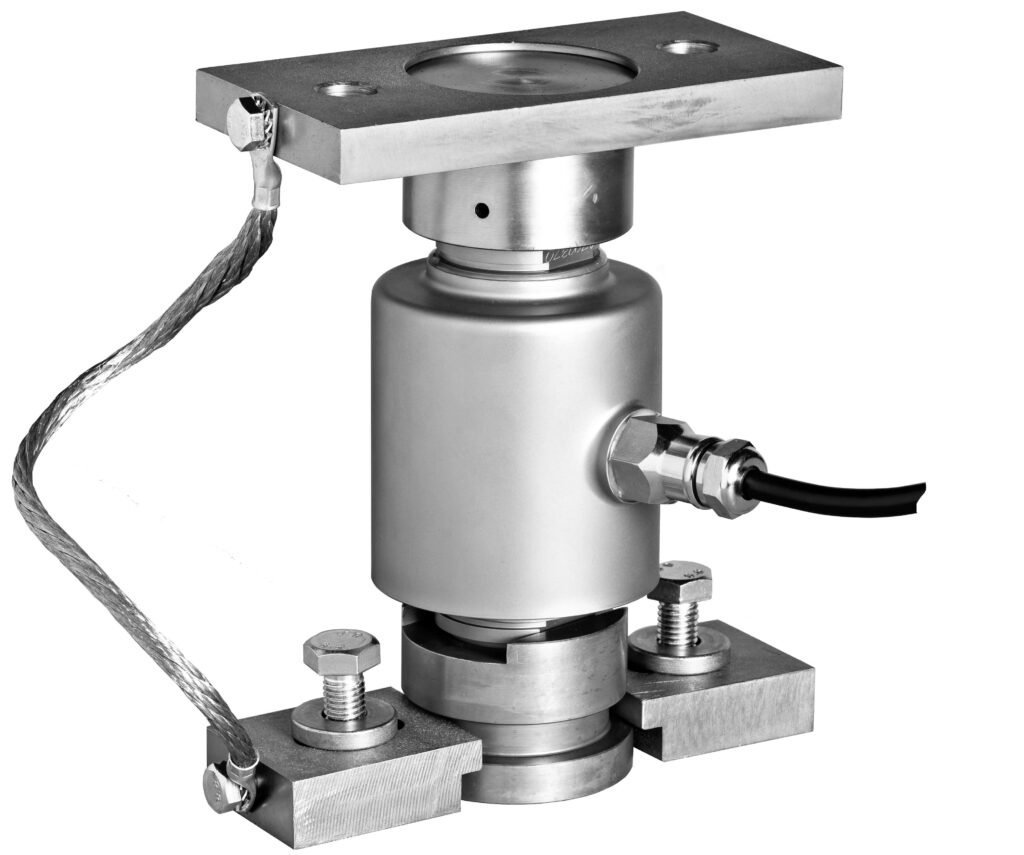

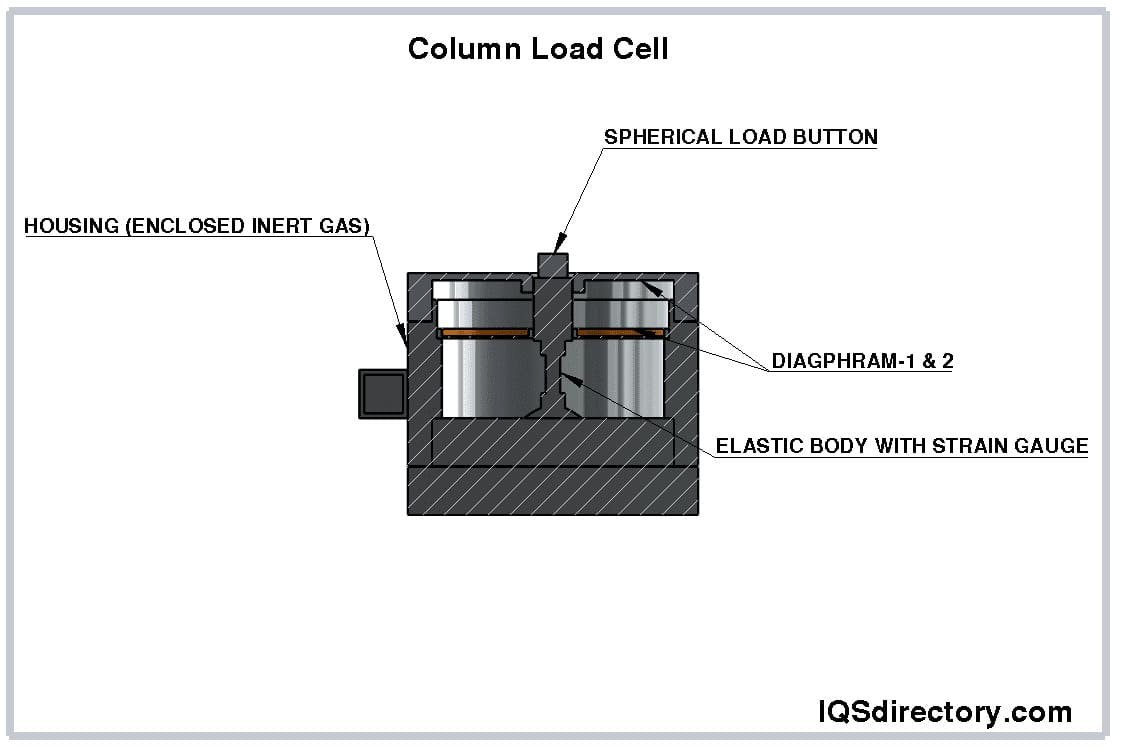

Compression load cells play a pivotal role in a variety of measurement tasks, operating on the principle of force application in the compression direction. These devices are a cornerstone in many industrial processes, where precise measurement of weight and force is paramount. At their core, these load cells feature a sturdy metal construction which undergoes deformation when subjected to pressure. This deformation is meticulously converted into an electrical signal, which is directly proportional to the magnitude of the force applied. Such a mechanism ensures accurate readings essential for applications ranging from intricate material testing to robust weighing systems in manufacturing lines. By transforming physical force into quantifiable electrical signals, compression load cells serve as critical components in ensuring the efficiency and reliability of industrial operations. Their adaptability and precision make them indispensable tools in achieving precise measurements critical for quality control and process optimization.

The Integration of Display in Compression Load Cells

The enhancement of compression load cells with the addition of a display feature marks a significant leap forward in measurement technology. This advancement simplifies the process of reading and interpreting data directly from the device, offering users immediate access to crucial information without the intermediary step of connecting to external data processing units. This direct readout capability streamlines operations, particularly in fast-paced or field environments where time and accuracy are of the essence. The display feature facilitates on-the-spot adjustments and decisions, empowering operators to react swiftly to the data presented. This not only boosts productivity but also enhances the user experience by making the management of measurement data more intuitive and less cumbersome. The immediate visual feedback provided by the display helps in quick troubleshooting and ensures that measurement processes remain uninterrupted.

Key Features of the eTAZsystems Compression Load Cell with Display

The eTAZsystems compression load cell with display stands out for its sophisticated design and functionality tailored to meet the needs of modern industrial applications. Highlighted by a high-resolution LCD screen, this load cell offers exceptional clarity in data visualization, allowing operators to easily read and interpret measurement results even in challenging lighting conditions. Customizable settings enable adaptation to a wide array of applications, ensuring that users can fine-tune the device for optimal performance across various operational contexts. A notable addition is its wireless connectivity feature, which facilitates remote monitoring of measurements, enabling users to access crucial data from a distance without physical interaction with the device. This capability is particularly useful in environments where the load cell is installed in hard-to-reach or hazardous areas. Crafted with durability in mind, the load cell utilizes top-grade materials, enhancing its accuracy over a broad range of conditions and extending its operational lifespan.

Benefits of Using a Compression Load Cell with Display

The integration of a display into compression load cells, such as the eTAZsystems model, brings forth a multitude of advantages that significantly enhance operational efficiency and data management. A primary benefit is the facilitation of immediate data visibility, which allows for quicker response times in adjusting processes and troubleshooting potential issues. This feature is particularly invaluable in environments where time-sensitive decisions are critical to maintaining workflow and productivity. Additionally, the elimination of reliance on external devices for data readout simplifies the setup and reduces clutter in the workspace, further streamlining operations. The ability to view measurements directly on the unit not only expedites data analysis but also reduces the risk of errors associated with data transfer, ensuring more reliable and accurate outcomes. This innovation supports a proactive approach to operational management.

Applications and Industries That Benefit the Most

The versatility of compression load cells with displays, such as those offered by eTAZsystems, opens up a myriad of applications across several key sectors. In the manufacturing realm, these devices are crucial for ensuring the precision of force applied during product assembly or in monitoring the weight of materials for quality control purposes. Transportation industries leverage these tools for accurate weight distribution assessments in vehicles, crucial for safety and regulatory compliance. Additionally, the construction industry benefits significantly from the ability to measure loads during the building process, ensuring structural integrity and compliance with engineering standards. Research facilities also rely on the precise data these load cells provide for material testing, pushing the boundaries of material science and engineering innovations. This widespread applicability underscores the critical role that compression load cells with displays play in enhancing operational efficiency, safety, and innovation across a diverse array of industries.

Installation and Maintenance Tips

For those integrating the eTAZsystems compression load cell with a display into their systems, adherence to the manufacturer’s installation instructions is crucial for obtaining accurate and reliable data. Mounting the load cell correctly, according to specified guidelines, ensures that it can accurately measure forces without interference or distortion. Calibration is a key step post-installation; it aligns the load cell’s output with known standards, ensuring the precision of measurements. Regular maintenance, including periodic recalibration and inspection for physical damage or wear, is essential for sustaining the load cell’s performance over time. It’s advisable to consult the eTAZsystems user manual for specific maintenance routines and troubleshooting steps. Additionally, keeping the load cell’s display clean and protected from harsh environmental conditions will aid in preserving its readability and functionality.

Future Trends in Compression Load Cell Technology

As the landscape of measurement technology evolves, compression load cell technology is not far behind, with several exciting developments on the horizon. We are on the cusp of seeing a broader integration of wireless and Internet of Things (IoT) capabilities, allowing for unprecedented real-time monitoring and data sharing across global networks. This will enable seamless communication between devices, enhancing the efficiency of remote operations and facilitating the management of large-scale industrial systems from anywhere in the world.

Another promising direction is the incorporation of advanced materials and nano-technology into load cell construction. These materials can significantly improve the durability, sensitivity, and longevity of compression load cells, even in the most demanding environments. This will be particularly beneficial for industries operating under extreme conditions, where traditional load cells may falter.

Furthermore, the potential integration of artificial intelligence (AI) and machine learning (ML) into compression load cell systems is set to revolutionize how data is processed and interpreted. AI can provide predictive maintenance insights, alerting operators to potential issues before they become problematic. Meanwhile, ML algorithms can optimize measurement accuracy by learning from vast datasets, adjusting for variables that may have previously introduced errors into measurements.

These advancements promise to make compression load cells more intelligent, versatile, and crucial than ever in the toolkit of industries reliant on precise force and weight measurement. As these technologies mature, we will likely see an even greater fusion of digital intelligence with physical measurement tools, setting new standards for precision, reliability, and operational efficiency in measurement technology.

CONCLUSION

In summary, the evolution of compression load cell technology, particularly with the integration of displays as seen in the eTAZsystems model, marks a significant leap in measurement capabilities across various industries. This advancement not only simplifies the process of data acquisition and interpretation but also enhances operational efficiency, accuracy, and safety. By providing immediate feedback through built-in displays, these devices empower users to make quicker, more informed decisions, directly impacting productivity and quality control. Furthermore, the forward-looking innovations in wireless connectivity, materials science, and artificial intelligence promise to elevate the functionality of compression load cells to new heights. As industries continue to demand more precise and reliable measurement tools, the role of advanced compression load cells will undoubtedly become more central. Embracing these innovations is key for any sector looking to optimize its processes and stay competitive in the modern industrial landscape.

FAQS

What are compression loads?

Under compressive load, the materials can only load up to a critical level after which bending deformation takes place. Bucking is considered as a critical property of many engineering materials and determines the failure criteria for a structure under high compressive load.

What is the working principle of load cell?

A load cell converts a force such as tension, compression, pressure, or torque into a signal (electrical, pneumatic or hydraulic pressure, or mechanical displacement indicator) that can be measured and standardized. It is a force transducer.

What is a capacitive load cell?

A capacitive load cell uses a series of capacitors to measure weight across the load cell. Inside each capacitor are two charged metal plates with a dielectric, uncharged material between them. This simple construction allows the capacitor to measure weight.

What is a tension load cell?

Tension load cells, as their name suggests, are predominantly used for measuring tension or pulling force. Many can also measure compression too, which makes them very versatile due to having bi-directional sensitivity. Tension load cells are often referred to as ‘S-type’ load cells due to their shape.