If you want to build a precise and accurate load cell system using Arduino, then understanding how to utilize the HX711 code is essential. Load cells are sensors that can measure weight or force, eTAZ systems making them ideal for applications such as industrial scales, robotic arms, and even smart home devices. By incorporating the HX711 module into your Arduino setup, you can enhance the performance and reliability of your load cell system. In this blog post, we will explore the basics of load cells, introduce the HX711 module, provide a step-by-step guide on implementing the HX711 load cell Arduino code, and discuss advanced applications of Arduino load cells.

Understanding the Basics of Load Cells and Arduino

At the core of many weight and force measurement systems are load cells, which are specialized sensors designed to convert a mechanical force into a digital signal. These devices operate on strain gauges, which change resistance when stretched or compressed, thus allowing the measurement of weight or force through electrical signals. On the other hand, Arduino serves as a versatile and accessible microcontroller platform, favored for its ease of use and open-source nature. It excels in collecting and processing data from various sensors, including load cells, and executing commands based on that data. When integrating load cells with an Arduino, users tap into a potent combination that can handle various applications, from simple weight scales to complex automation systems. The key to harnessing this power lies in understanding both the physical properties and limitations of load cells and the technical capabilities of the Arduino platform.

- Selecting the suitable load cell for the specific application.

- Accurately reading its output with Arduino.

- Effectively translating this data into actionable insights or controls.

Introduction to HX711 and Its Role in Load Measurement

The HX711 module is a critical component in load cell systems, functioning as a precise 24-bit analog-to-digital converter (ADC). This specialized module is engineered for high-accuracy weight and force measurement applications, making it indispensable in both weigh scales and industrial controls. The HX711 features an integrated amplifier and a signal conditioning circuit at its core. These elements are crucial for enhancing the signal quality from the load cell, ensuring that the measurements are accurate and have high resolution. The HX711 allows an Arduino microcontroller to quickly process and interpret the information by converting analog signals from the load cell into digital data. This capability transforms raw mechanical force into meaningful, actionable digital data, bridging the gap between physical weight measurements and digital computing.

Building Your Arduino Load Cell System with eTAZ Systems

eTAZ Systems provides an extensive array of load cell modules tailored for seamless integration with Arduino and the HX711 module, streamlining the construction of a dependable and precise measurement system. Leveraging these modules, users can select the load cell that best matches their project requirements, ensuring optimal performance and accuracy for their specific application. Additionally, eTAZ Systems extends valuable support and a wealth of resources to assist users in effectively incorporating load cells into their projects. This support includes detailed guides on connecting your load cell to an Arduino board via the HX711 module, ensuring a smooth and successful setup process. With eTAZ Systems, hobbyists and professionals gain access to the essential components and expert guidance needed to bring their load cell projects to fruition, enabling them to focus on application development and innovation rather than the intricacies of hardware integration.

Step-by-Step Guide to Implementing HX711 Load Cell Arduino Code

First, To integrate the HX711 load cell with your Arduino, ensure the HX711 library is added to your Arduino IDE. This is accomplished by opening the Library Manager within the IDE and searching for “HX711”. Install the library, and you’re ready for the next steps.

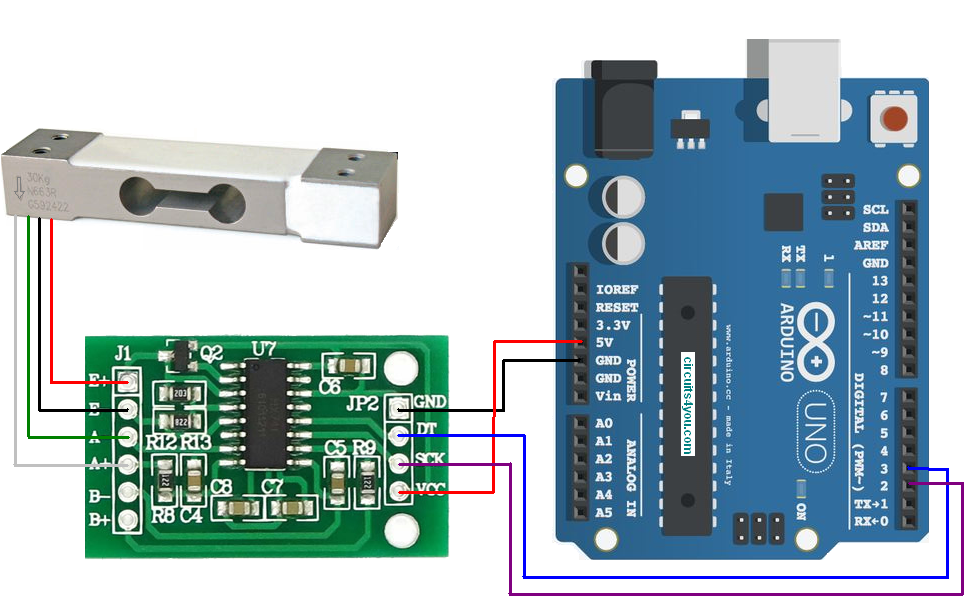

Next, connect the HX711 module to your Arduino. Typically, this involves connecting the HX711’s VCC and GND pins to the 5V and ground on the Arduino, respectively. The HX711’s data and clock pins then connect to two digital pins on the Arduino—these pins will be specified in your code.

With the hardware set up, open the Arduino IDE and load one of the example sketches provided with the HX711 library. These examples are invaluable for understanding how to calibrate your load cell. Calibration is critical, as it ensures the accuracy of the measurements obtained from the load cell. Follow the instructions within the example sketch to calibrate your system. This usually involves placing a known weight on the load cell and adjusting the calibration factor in the sketch accordingly.

Finally, once calibration is complete, you can modify the sketch to suit your project’s specific needs, whether logging data to an SD card, displaying readings on an LCD, or triggering actions based on particular weight thresholds. The flexibility of the HX711 library paired with the Arduino platform allows for a wide range of applications, from simple household scales to more complex industrial measurement systems.

Troubleshooting Common Issues in Arduino Load Cell Systems

Attention to detail is vital in tackling common Arduino load cell systems issues.

To minimize noisy readings, ensure stable power supply connections and utilize twisted pair wires for signal lines to reduce electromagnetic interference. Additionally, incorporating low-pass filters in your code can help smooth out erratic data. Drift, or gradual deviation in sensor readings, often stems from environmental factors such as temperature changes. Implementing compensation algorithms within your code can adjust readings to account for these fluctuations.

To correct calibration errors, often recalibrate the load cell with known weights to ensure measurement accuracy. Also, check the load cell’s mounting and ensure no mechanical binding affects its movement.

To correct calibration errors, recalibrate the load cell with known weights to ensure measurement accuracy.

Also, mount the load cell correctly and ensure that no mechanical binding affects its movement.

Exploring Advanced Applications of Arduino Load Cells

Arduino load cells open the door to many sophisticated uses, transcending traditional weight and force measurement tasks. When paired with the Arduino platform’s flexibility, these versatile components enable the creation of highly intricate systems for robotics and automation projects. In robotics, Arduino load cells can serve as critical feedback mechanisms, allowing robots to adjust grip strength on objects, preventing damage to delicate items while ensuring a secure hold on heavier ones. This application is crucial in manufacturing and packaging industries where precision and adaptability are paramount.

Integrating load cells with Arduino can lead to the development of intelligent inventory management systems in the realm of automation. These systems can automatically monitor stock levels, alerting when supplies run low or when an unexpected weight change could indicate leakage or loss. Moreover, combining load cells with IoT (Internet of Things) technology paves the way for remote monitoring and control solutions. For instance, agricultural applications can benefit from dynamic soil pressure monitoring, providing insights into soil health and moisture levels to optimize irrigation and planting strategies.

Additionally, developers can create comprehensive health and safety monitoring systems by integrating load cells with other sensors. These systems could monitor the structural integrity of buildings or bridges, detecting strain and load changes that may signify potential issues long before they become critical. This application not only showcases the advanced potential of Arduino load cells in ensuring public safety but also underscores the transformative impact of these technologies in engineering and construction.

Conclusion

In wrapping up, integrating the HX711 module with an Arduino load cell system offers unparalleled accuracy and reliability for various applications, from essential weight measurement to advanced automation and safety systems. This guide has provided a comprehensive overview of how to implement the HX711 load cell Arduino code effectively, ensuring that even those new to Arduino can confidently undertake their projects. By understanding the basics of load cells, leveraging the capabilities of the HX711, and utilizing the resources available from eTAZ Systems, hobbyists and professionals alike can create sophisticated measurement and control systems. Troubleshooting common issues will further enhance system reliability and performance, opening the door to innovative applications that stretch the imagination. Whether you’re building an intelligent inventory system, a robotic assistant, or a safety monitor, the Arduino load cell system, supported by the HX711, is a cornerstone technology that brings your projects to life with precision and versatility.