Through hollow load cells are an vital thing in a wide variety of business applications, presenting correct and dependable size of force and weight. When combined with eTAZ systems, those load cells offer even greater performance and overall performance. In this weblog submit, we are able to explore the blessings of the usage of via hole load cellular-eTAZ systems structures, in addition to provide suggestions for installation and speak future developments in via hole load cell technology.

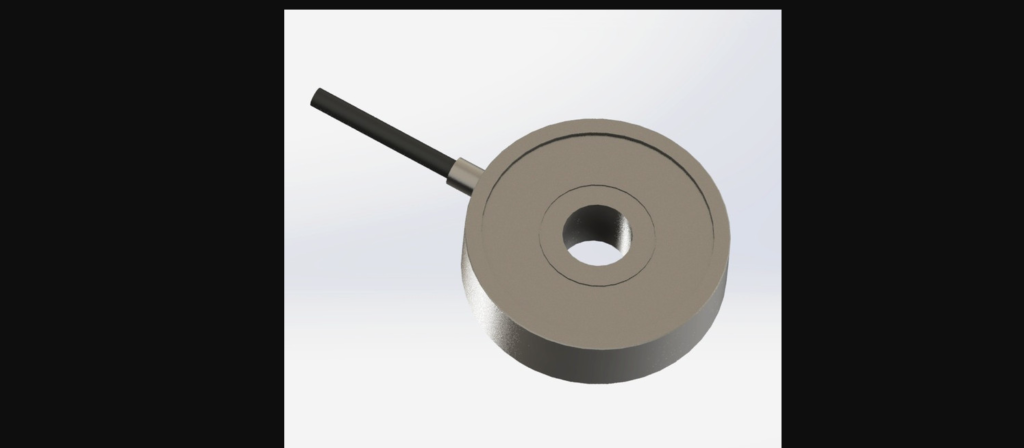

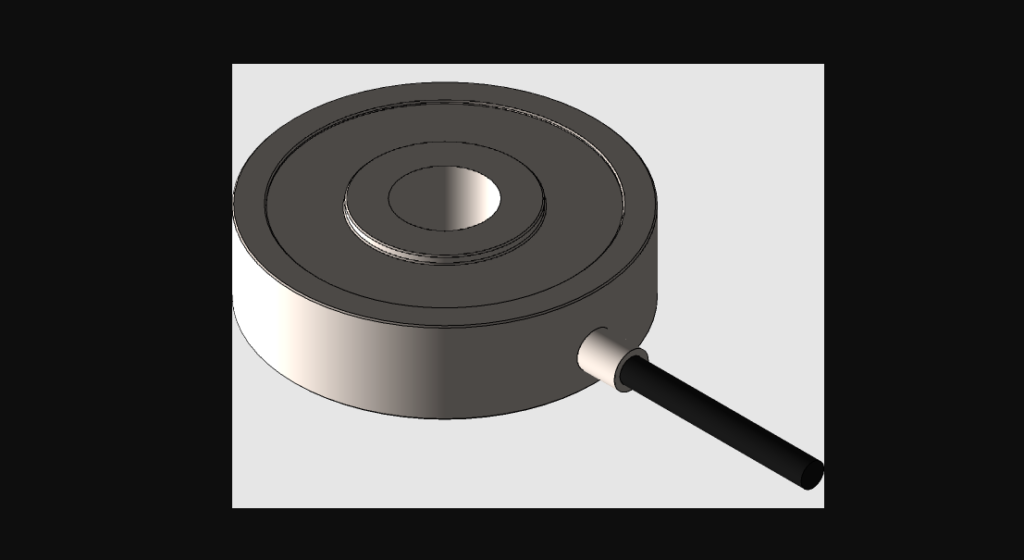

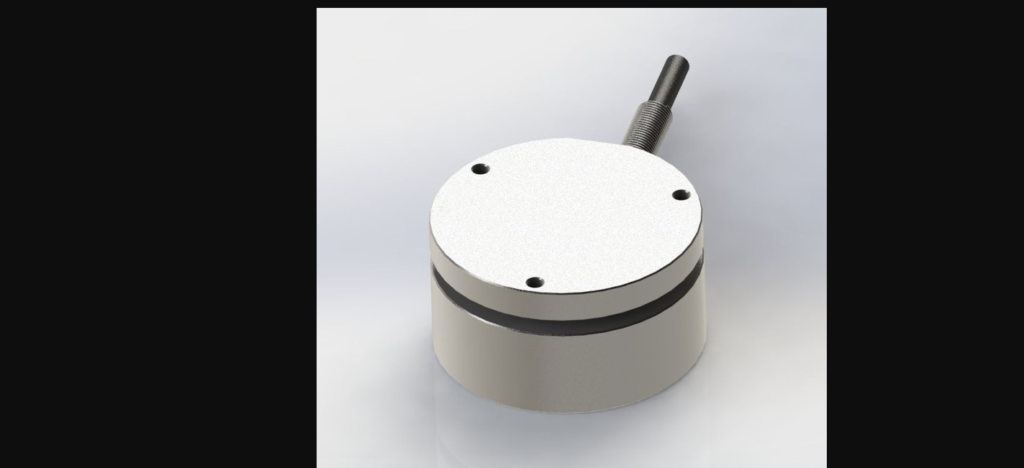

Understanding Through Hole Load Cells

Through hole load cells stand out for his or her unique design, featuring a critical hole that without delay channels force or weight onto the sensor. This innovative configuration now not best helps the suitable measurement of forces in difficult packages but also broadens the scope of environments where conventional load cells might fall brief. Predominantly embraced inside the aerospace, automobile, and production sectors, those devices play a pivotal function in ensuring accuracy and reliability wherein it topics maximum. The central aperture of a through hollow load mobile isn’t always merely a structural feature; it’s a gateway to more desirable size skills.By allowing immediate application of pressure, it eliminates the complications and inaccuracies that can arise with external mounting and force switch mechanisms.

Introduction to eTAZ Systems

eTAZ structures constitute a groundbreaking development within the realm of digital tracking and statistics evaluation, designed to paintings seamlessly with load cells to enhance operational efficiency. Engineers design these structures to capture and process force dimension records in real time, offering a range of functionalities that are valuable to modern business operations.. With competencies like facts logging, which permits the monitoring of measurements over the years, and remote tracking, that allows operators to examine machine performance from everywhere, eTAZ systems are transforming how industries method pressure size. Alarm notifications are some other key characteristic, alerting personnel to capacity issues earlier than they improve into critical issues, hence retaining continuous operational integrity.

The integration with through hollow load cells is in which eTAZ structures certainly shine, developing a symbiotic dating that maximizes the utility and accuracy of pressure measurements.

“This integration facilitates a streamlined method for taking pictures and reading facts, paving the way for improvements in monitoring force and weight across various applications.”

The real-time facts skills provided by using eTAZ systems ensure that choice-makers have instantaneous get right of entry to to crucial operational metrics, enhancing reaction times to any springing up troubles and fostering a proactive in preference to reactive control fashion. This superior degree of tracking and evaluation is instrumental in pushing the boundaries of what is viable in industrial measurement and manage, marking eTAZ structures as a cornerstone generation within the evolution of precision pressure and weight size strategies.

The Benefits of Using Through Hole Load Cell in eTAZ Systems

Integrating through hollow load cells with eTAZ systems drastically elevates operational skills inside commercial settings. This synergistic pairing harnesses the precision of through hole load cells, which can be engineered for direct force dimension, with the superior tracking and analytical energy of eTAZ structures. Key blessings include the ability to reveal forces and weights in real-time, making sure information isn’t best accurate but additionally immediately available for analysis. This integration allows industries to have a finer manipulate over their procedures, main to better productiveness. Additionally, the faraway get admission to characteristic of eTAZ structures lets in for the monitoring of system performance from any vicinity, facilitating timely troubleshooting and reducing pointless downtime. Another widespread advantage is the reduction in protection prices, as predictive analytics can sign the need for renovation before luxurious breakdowns arise.

Applications of Through Hole Load Cell-eTAZ Systems

The integration of via hole load cells with eTAZ structures unearths its relevance across a huge spectrum of industries, enabling unique pressure and weight tracking essential for operational excellence. These advanced structures have verified quintessential inside the aerospace zone, where they are utilized for rigorous structural aspect testing, making sure the reliability and protection of aircraft. Automotive producers leverage these systems to evaluate the performance and durability of numerous additives underneath strain, helping in the design of extra strong motors.

In the manufacturing realm, the want for unique weight and force measurement is paramount, with via hollow load cellular-eTAZ systems gambling a important position in preserving constant first-class and performance in manufacturing traces. These structures also are vital in fabric trying out laboratories, in which researchers depend on them for correct pressure dimension within the development of latest materials and products.

Furthermore, the versatility of those structures extends to the monitoring of machinery for anxiety and compression forces, imparting essential facts that allows prevent gadget failure and optimize overall performance. The logistics and transportation industries benefit from the weight dimension skills of these structures, which are indispensable to the control of cargo and ensuring compliance with weight guidelines.

By facilitating actual-time tracking and facts evaluation, through hole load cell-eTAZ systems help industries in attaining higher precision, performance, and reliability in their operations, underscoring their huge applicability and importance.

Installation Tips for Through Hole Load Cell-eTAZ Systems

To ensure the successful deployment of through hollow load mobile-eTAZ systems, adhering to positive set up ideas is crucial. Firstly, aligning the weight cellular efficiently is essential for correct force dimension. Misalignment can introduce errors and impact the overall performance of the device. Use the mounting hardware advocated through the producer to secure the burden mobile firmly in place, preventing any movement that might have an effect on its accuracy.

Wiring and electrical connections need to be made according with the producer’s specs. Incorrect wiring can lead to signal noise, erroneous facts, or even damage to the gadget. Pay near attention to shielding and grounding techniques to limit interference from outside electric sources.

Regular preservation and calibration are key to maintaining the accuracy and reliability of via hollow load mobile-eTAZ systems. Establish a habitual calibration schedule based at the operational needs and surroundings of the gadget. This guarantees that the weight cellular continues to provide specific measurements over time.

Implementing effective facts logging and tracking processes is also critical. This allows the actual-time tracking and evaluation of pressure measurements, facilitating short modifications to hold foremost machine overall performance. By following these guidelines, you may maximize the efficiency and sturdiness of thru hollow load cell-eTAZ systems in any utility.

Future Trends in Through Hole Load Cell Technology

Thru hollow load cellular technology is progressing with innovative developments to enhance its utility and flexibility in response to evolving industrial needs. Anticipated improvements encompass the incorporation of IoT capabilities, permitting these devices to no longer most effective speak wirelessly but additionally to integrate seamlessly into a networked environment of business sensors and actuators. This jump ahead will facilitate exceptional tiers of statistics series and analysis, beginning doors to predictive analytics and automated gadget adjustments primarily based on real-time feedback. Additionally, there may be a strong push towards enhancing the environmental resilience of those sensors, ensuring that they could supply constant and dependable overall performance even in the most difficult conditions, consisting of excessive temperatures, high humidity, or corrosive atmospheres.

FAQS

Certainly! Here are some commonly requested questions on through hole load cell-eTAZ systems:

Q: Are via hollow load cell-eTAZ systems adaptable for use in environments uncovered to the factors?

A: Absolutely, via hollow load cellular-eTAZ structures are certainly able to functioning in outside settings. They need to ensure they have the suitable sealing and environmental protections for operating in such conditions.

Q: What is the recommended frequency for calibrating thru hollow load cellular-eTAZ systems?

“We must decide the calibration frequency for thru hollow load cellular-eTAZ structures primarily based on their specific use and application demands. It is recommended to follow regular calibration intervals to maintain measurement accuracy and ensure machine reliability.”

Q: Can via hollow load mobile-eTAZ systems perform correctly in environments with elevated temperatures?

“Yes, eTAZ systems design via hole load cells specifically to withstand high-temperature conditions. It’s crucial to select a load cell rated for your application’s specific temperature range to ensure its proper capacity and durability.”