eTAZ systems PCB Design is a crucial aspect of modern electronics manufacturing, ensuring electronic components are interconnected and functioning correctly. Understanding the different types of PCBs can help designers optimize their designs for specific applications. This blog post will delve into the various PCB types, from traditional rigid PCBs to innovative flexible and high-frequency PCBs.

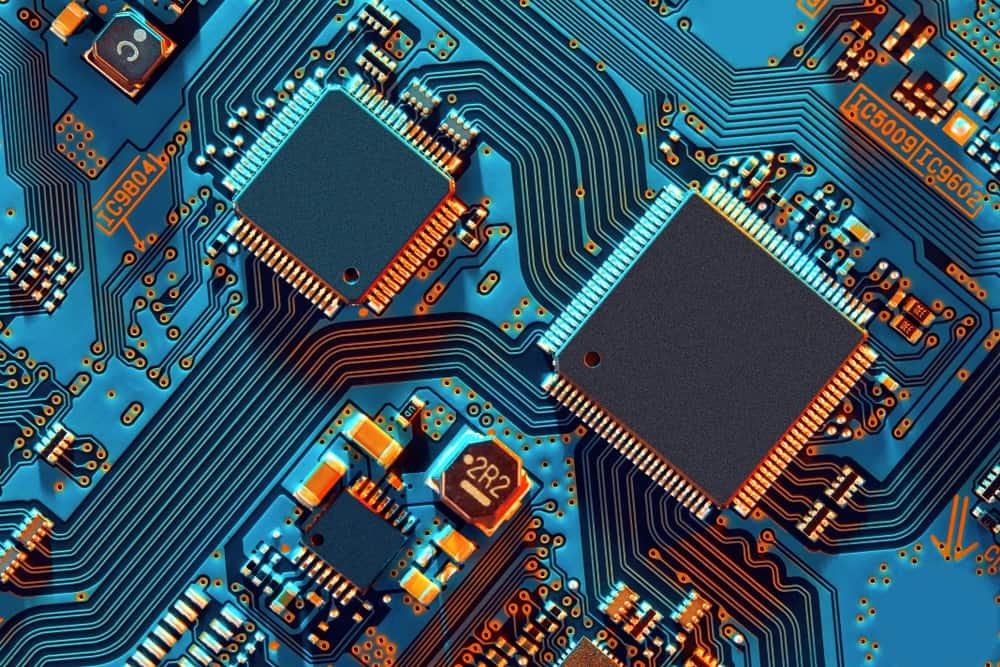

An Introduction to PCB Design and Its Importance

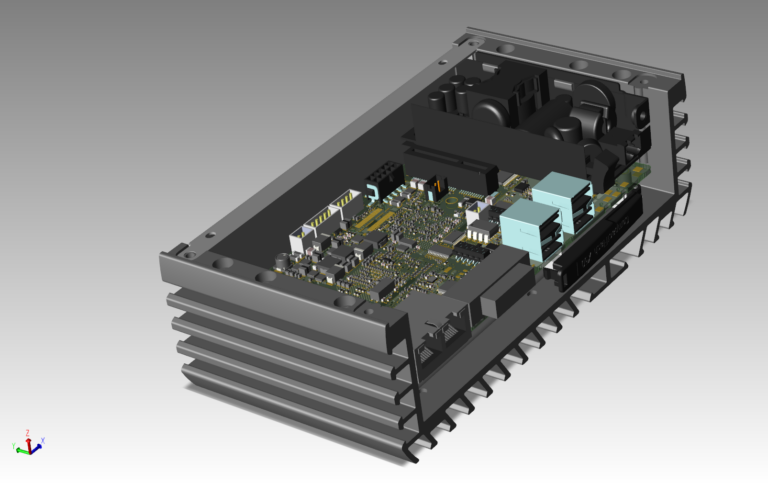

At the heart of every electronic device lies a Printed Circuit Board (PCB), the foundation upon which electrical components are mounted and interconnected. The art and science of PCB design are critical in transforming theoretical electronic schematics into practical, workable hardware. This intricate process involves determining the precise layout of components on the PCB, establishing their connections through etched pathways, and ensuring that the assembly operates as intended within the device. The significance of PCB design cannot be overstated; it directly influences the final product’s electrical performance, reliability, and efficiency. By meticulously planning and executing the PCB layout, designers can address and mitigate potential issues such as electrical noise, interference, and heat dissipation. This enhances the device’s functionality, longevity, and user satisfaction. As technology evolves and devices become more complex, the role of PCB design grows increasingly vital, pushing the boundaries of what’s possible in the electronics industry.

The Various Layers of Complexity in PCB Design

PCB design complexity varies dramatically based on the project’s requirements and the type of PCB utilized. The complexity is not merely physical, involving multiple layers stacked upon one another, each hosting its unique components and circuitry. It extends into the realm of design considerations that must be juggled concurrently. Designers face the intricate task of navigating signal integrity, ensuring robust power distribution, and effective thermal management strategies. This complexity is compounded when integrating advanced functionalities and adhering to the stringent size constraints of modern electronic devices. The designer’s role becomes increasingly challenging as designs shift from simple single-layer boards to more complex multi-layered arrangements. They must optimize the placement of components to maximize board real estate while minimizing signal path lengths and potential interference. Additionally, the advent of new technologies and materials introduces another layer of complexity.

Unveiling the Different Types of PCBs

Exploring the diversity of Printed Circuit Boards reveals a spectrum tailored for various functionalities and application needs. Beyond the traditional rigid PCBs constructed from sturdy fibreglass, the landscape includes adaptable and bendable flexible PCBs crafted from materials that accommodate contours and movement. This category extends to rigid-flex PCBs, which merge the structural integrity of rigid PCBs with the versatility of flexible ones, offering a hybrid solution for dynamic and space-constrained designs. High-frequency PCBs stand out for applications demanding high-speed performance. These are built with specialized materials to ensure minimal signal loss and optimal integrity when speed is paramount. Metal core PCBs also play a critical role, particularly in scenarios necessitating enhanced heat dissipation capabilities, such as LED lighting systems. Each PCB type serves a unique set of requirements, reflecting the vast possibilities in electronic design and the continuous innovation to address specific technological challenges.

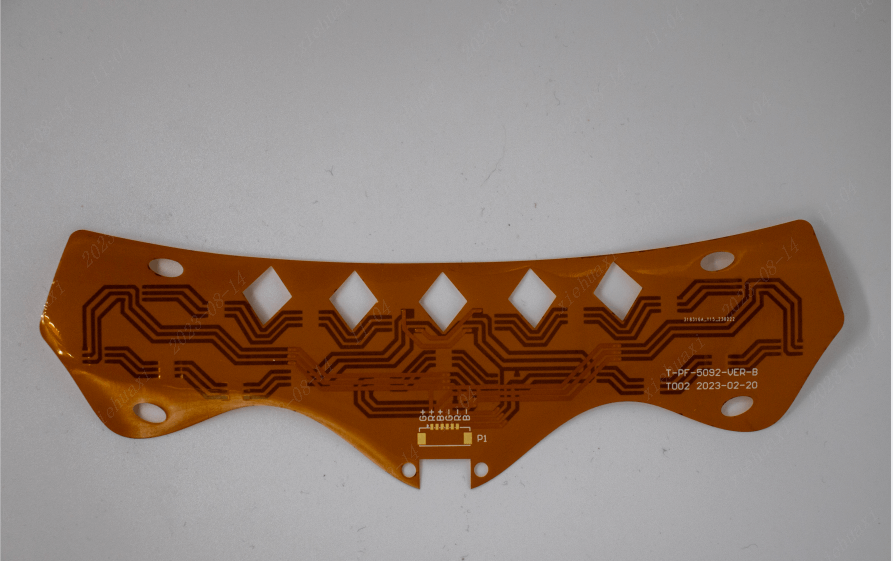

Flexible PCBs: Revolutionizing Electronics Design

The advent of flexible PCBs has marked a significant shift in the paradigm of electronics design, facilitating the development of more compact, lightweight, and capable of assuming unconventional shapes and configurations. These innovative PCBs leverage pliable materials, allowing them to bend and flex during use without compromising their functionality. This attribute is particularly beneficial in industries where electronic devices must fit into irregular spaces or adapt to moving parts, such as wearable technology, medical diagnostic equipment, and automotive electronics. Flexible PCBs eliminate the constraints imposed by traditional rigid boards, offering unparalleled freedom in design. Their versatility extends to various applications, enabling designers to explore new product development and functionality horizons. By integrating flexible PCBs into their designs, engineers can achieve complex, high-performance circuits in form factors previously unattainable, pushing the boundaries of what’s possible in electronic device innovation.

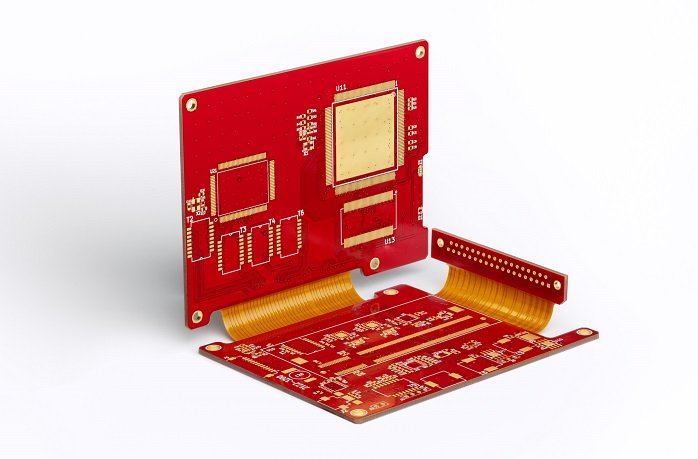

The Significance of Rigid-Flex PCBs in Modern Devices

Rigid-flex PCBs represent a groundbreaking fusion of traditional rigidity and modern flexibility within circuit board technology. By incorporating elements of both rigid and flexible PCBs into a single unified design, these hybrid boards offer a unique solution that caters to the demanding requirements of today’s sophisticated electronic devices. Ideal for applications necessitating a blend of structural stability and design versatility, rigid-flex PCBs facilitate intricate electronic configurations that are both durable and adaptable. This dual nature enables the integration of more complex and compact electronics into spaces and forms that would otherwise be impossible with conventional PCBs alone. Utilized across various industries, including medical devices, consumer electronics, and aerospace technology, rigid-flex PCBs epitomize the innovative approach to overcoming design constraints, allowing for the seamless incorporation of electronic components into devices where space is at a premium and flexibility is paramount.

High-Frequency PCBs: Meeting the Demand for Speed

In the rapidly advancing world of electronics, the requirement for swift data communication has never been more critical. High-frequency PCBs stand at the forefront of this need, meticulously engineered to cater to applications where speed is of the essence. Constructed using materials specifically chosen for their low dielectric loss and high thermal stability, these PCBs minimize signal degradation even at elevated frequencies. The design process for high-frequency PCBs is meticulous, focusing on preserving signal integrity across the board. Designers employ techniques such as impedance control and careful routing of signal paths to prevent delays and reduce the risk of cross-talk between signals, which can be particularly challenging in environments that demand high-speed data transfer. Applications in fields such as radar systems, satellite communication, and high-speed computing rely on the capabilities of high-frequency PCBs to maintain efficient and reliable operation.

Navigating the Challenges of PCB Design

In the realm of PCB design, the journey from concept to functional circuit board is fraught with obstacles that test the ingenuity and foresight of designers. Among the foremost challenges is ensuring signal integrity, which involves minimizing noise and preserving the quality of electrical signals across the PCB. This task is particularly daunting in densely packed, multi-layered boards with a high risk of interference. Additionally, achieving efficient power distribution requires meticulous planning to avoid voltage drops and ensure that all components receive stable power, which is critical for the device’s reliability and performance.

Thermal management is another hurdle, as designers must anticipate and mitigate the heat generated by electronic components during operation. Without effective heat dissipation strategies, there’s a risk of overheating, which can degrade component performance or lead to failure. Moreover, the complexity of modern PCB designs brings manufacturability into focus.

Designers need to navigate the trade-offs between complexity and the practical aspects of manufacturing to ensure accurate, affordable, and scalable production of their designs.

Employing advanced design software and methodologies, designers tackle these challenges head-on. They refine their PCB designs through simulation and testing, balancing the competing demands of form, function, and fabrication. This intricate dance between innovation and pragmatism propels the field of PCB design forward, overcoming hurdles to bring sophisticated electronic devices from blueprint to reality.