A strain gauge load cellular is a essential aspect in lots of business applications, supplying specific measurements of weight and pressure. Understanding the operating principle behind pressure gauge load cells is critical for all and sundry worried in designing or running structures that depend on correct weight measurements. In this weblog submit, we will delve into the core concept of pressure size, the role of the Wheatstone Bridge in sign conversion, and the incorporation of strain gauge load cells into the eTAZsystems . Additionally, we will explore the diverse real-global applications of strain gauge load cells and answer regularly requested questions about their operation.

Understanding Strain Gauge Load Cells

Strain gauge load cells feature as transducers, successfully changing force or weight exerted onto them into a measurable electrical sign. At their middle lies the stress gauge, a especially designed steel strip touchy to physical force. Deformation is experienced by the strain gauge when a force is applied, causing the duration and diameter of the metallic strip to change. This physical trade leads to a variation in its electric resistance, a phenomenon that is the backbone of the way those load cells gauge the magnitude of force or weight carried out. The sensitivity of the stress gauge to even mild deformations makes stress gauge load cells pretty accurate and reliable for precise measurements in numerous packages. This capability to hit upon and quantify forces appropriately makes pressure gauge load cells critical in fields that demand exactness in weight and pressure measurement.

The Core Concept of Strain Measurement

The essence of strain dimension hinges on knowledge how materials respond beneath pressure. Essentially, when a fabric is subjected to an outside force, a distortion within the fabric’s shape or quantity is induced. This bodily alteration is an immediate effect of stress acting at the material, leading to a rearrangement of its molecular shape and affecting its electric resistance. In the context of pressure gauge load cells, the quantity of deformation is exploited to be stumbled upon and measured using this principle. As the cloth—regularly a metal foil in pressure gauges—undergoes stress, its electric resistance modifications predictably. This version in resistance is critical as it serves as the measurable output that correlates directly to the pressure implemented. The quantity of stress on the cloth may be appropriately quantified via particular measurement of this resistance exchange.

How Strain Gauge Load Cells Work

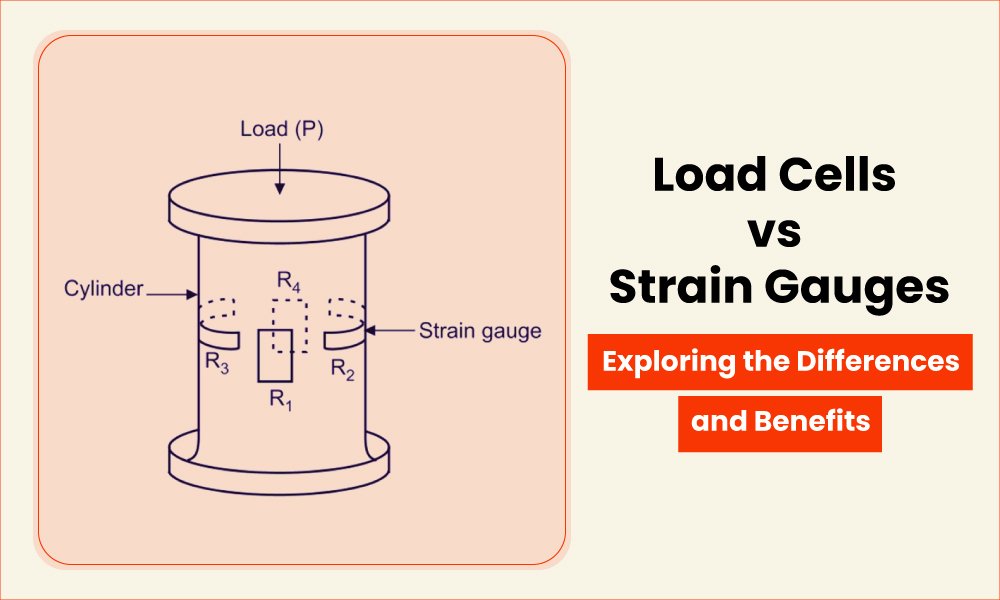

In the heart of strain gauge load cells is a strategic arrangement of strain gauges that form a critical part of the Wheatstone Bridge circuit. The placement of the strain gauges in the load cell structure is meticulous, typically configuring them to optimize their sensitivity to stress. When an outside force, whether weight or strain, applies to the weight mobile, it results in the physical deformation of the strain gauges. This deformation at once influences the electric resistance of the stress gauges, a phenomenon intrinsically linked to their physical elongation or compression.

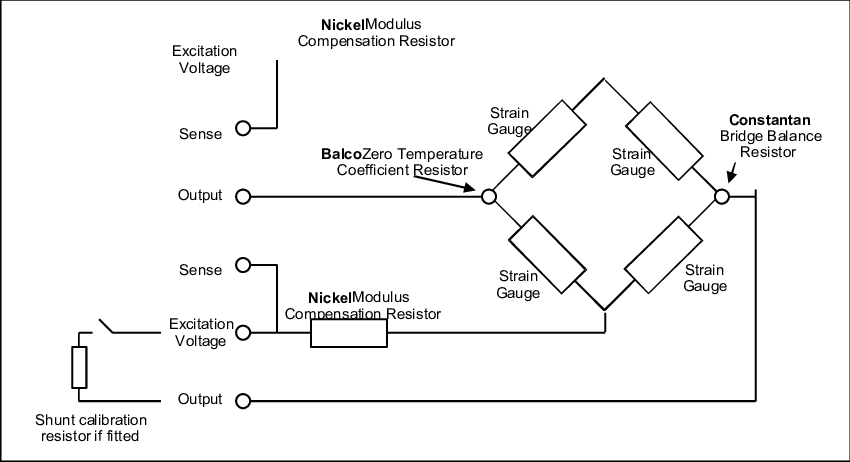

As the pressure gauge resistance changes, it disrupts the equilibrium of the Wheatstone Bridge circuit, ensuing in a detectable imbalance. This imbalance manifests as a measurable voltage differential across the bridge. Then, interpret and amplify the voltage difference in order to provide a readable output, correlating without delay to the value of the pressure implemented. The capacity to transform mechanical deformation into an electrical sign with high precision allows pressure gauge load cells to offer distinctly accurate and reliable measurements, important for the sizable array of programs they serve in ultra-modern industries.

The Role of the Wheatstone Bridge in Signal Conversion

Central to translating the bodily deformation of pressure gauges into quantifiable electric signals, the Wheatstone Bridge serves as the linchpin. Furthermore this ingenious circuit consists of four resistors organized in a diamond shape, with pressure gauges integrated as two of those resistive elements. The pressure gauges change their physical nation upon making use of force, changing their electrical resistance. This alteration disrupts the formerly balanced nation of the Wheatstone Bridge, growing a voltage discrepancy across its output terminals. This voltage difference is directly proportional to the force exerted, allowing unique calculation of the carried out weight or pressure. The brilliance of the Wheatstone Bridge lies in its capacity to transform minute adjustments in resistance into a measurable electric output, for this reason facilitating the correct interpretation of strain gauge readings. Besides Through meticulous calibration, this setup guarantees that the strain gauge load cellular can supply genuine weight and pressure measurements.

Incorporating Strain Gauge Load Cells into the eTAZsystems

The eTAZsystems represents a present day integration of generation designed to decorate accuracy and performance in weight dimension processes across numerous industries. Similarly by embedding stress gauge load cells into the eTAZsystems , this revolutionary method leverages those sensors’ specific and dependable competencies to screen and control the burden of materials in real time. This seamless integration allows advanced operational productiveness and notably complements great manage measures. Likewise the adaptability of strain gauge load cells to degree anxiety and compression permits eTAZsystems to cater to numerous dimension desires, from sensitive laboratory balances to sturdy business scales. Incorporating these load cells into the device structure ensures that the eTAZsystems can deliver remarkable precision in weight measurement, optimizing tactics wherein accuracy is paramount. This strategic utility of strain gauge load cells underscores their significance in advancing technological solutions that meet the evolving demands of modern industries.

Applications and Real-World Uses of Strain Gauge Load Cells

“Many sectors depend on strain gauge load cells, which serve as the backbone for structures requiring nuanced weight and force measurements. Particularly The aerospace industry relies upon these gadgets for structural testing, assessing the safety and durability of components under diverse pressure situations. Automotive producers integrate strain gauge load cells into trying out rigs to assess vehicle durability and cargo managing capabilities, imparting precious records that influences design and safety standards. Furthermore, those load cells are essential to the capability of scientific equipment, together with patient weighing systems and force monitoring in surgical tools, wherein accuracy is non-negotiable. The adaptability of pressure gauge load cells to laboratory and rugged business environments showcases their unparalleled versatility.

FAQS

Frequently requested questions shed mild on normal curiosities and technical inquiries regarding stress gauge load cells. One such query issues their capability to measure each anxiety and compression forces. “These load cells correctly seize records for a wide range of troops, showcasing their versatility in application. Troops frequently raise calibration queries; we calibrate them using precision weights or forces, allowing us to fine-tune the equipment to maintain accuracy over time. Regarding the durability of strain gauge load cells, note that their lifespan can vary.” Factors influencing longevity encompass the running surroundings, frequency of use, and adherence to recommended preservation protocols .With appropriate care, these load cells can supply unique measurements for an extended duration, helping numerous industrial and studies applications.

CONCLUSION

In summarizing the significance of strain gauge load cells, it is evident that those devices are foundational to ensuring precision in weight and force measurement across a large spectrum of industries. Additionally from the problematic workings of the Wheatstone Bridge in signal conversion to integrating those cells into sophisticated structures like the eTAZsystems , their role is undeniably central to advancing technological talents in measurement. “The versatility and reliability of strain gauge load cells underscore their exploration in operation, ranging from the primary precept of strain size to real-world applications. Above all Situations where accuracy isn’t just preferred but required, make pressure gauge load cells crucial. As industries continue to conform and demand more precise and efficient measurement solutions, the significance of pressure gauge load cells is poised to grow.

Pingback: PCB Design through eTAZ Systems -