Have you ever puzzled how does a load cellular sensor paintings? Load cells are important components in diverse industries, assisting to degree weight and pressure appropriately. Understanding the capability of Load Cell Sensors can offer precious insights into their packages and benefits. In this blog put up, we are able to discover the working standards of load mobile sensors, the position of stress gauges, exclusive forms of load cells, the improvements supplied by means of eTAZ systems, practical programs, common troubles, and the destiny of load mobile era.

Understanding the Basics of Load Cell Sensors

At the heart of weight and pressure size in numerous packages lies the weight cell sensor, a complicated device engineered to transduce carried out forces into quantifiable electrical indicators. This transformation occurs through the deformation of the sensor under load, which in flip alters its electrical resistance in a measurable way. The importance of this resistance exchange immediately correlates to the force exerted, making an allowance for unique dimension. The design intricacies, cloth choice, and methodical calibration of those sensors are pivotal in reaching excessive sensitivity and accuracy in readings.

Engineers employ various configurations and substances to construct Load Cell Sensors, catering to numerous programs and influencing the sensor’s overall performance traits, including its range, durability, and reaction time.

This foundational knowledge units the stage for exploring the wider implications and packages of load cellular generation throughout industries, emphasizing

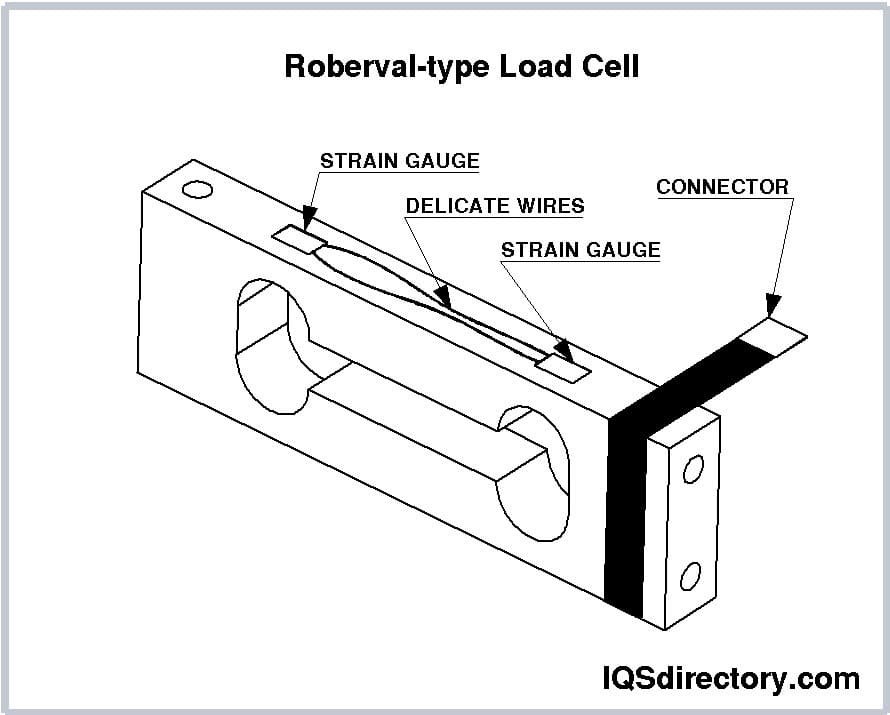

The Role of Strain Gauges in Load Cells

Central to the operation of load mobile sensors, stress gauges play a pivotal position in translating physical forces into decipherable electric alerts.

When the cell carries a load, it deforms in shape. Strain gauges, meticulously bonded to the floor of the load cell, precisely measure this deformation.

As the cellular deforms, so do the stress gauges, leading to a variation in their electric resistance.

This variant immediately responds to the amount of stress experienced by the load mobile, and by measuring this resistance change, one can accurately determine the applied force or weight.

Strain gauges are available a variety of types, which include foil, semiconductor, and skinny-movie, each decided on based totally at the precise requirements and sensitivities wished for the software handy.

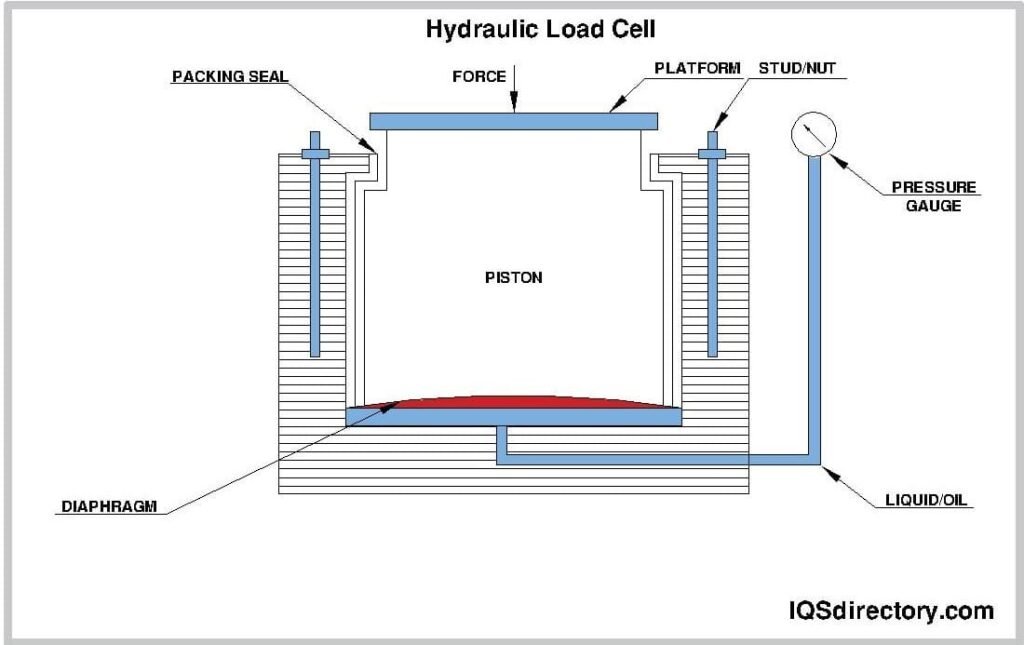

Exploring Different Types of Load Cells

Ingeniously designed load cells cater to unique dimension desires across numerous sectors, with their types differentiated particularly by the manner in which they respond to applied loads.

For instance, compression load cells excel in environments wherein the pressure carried out pushes down on the mobile, making them vital in scales and commercial compression trying out.

Tension load cells, on the other hand, excel in situations where force is pulled away from the sensor, playing important roles in crane scales and hanging weight measurements. Users regularly deploy shear beam load cells, known for their accuracy, in tank and hopper weighing, utilizing their design that effectively handles both shear and bending forces.

Bending beam load cells offer versatility and sturdiness, particularly desired in platform scales and conveyor systems. Each kind’s precise mechanical structure influences its sensitivity, accuracy, and suitability

How eTAZ Systems Enhance Load Cell Performance

eTAZ systems constitute a jump forward in load cellular technology, offering enhancements that considerably enhance the functionality and reliability of those sensors. Through the utility of superior digital sign processing, eTAZ structures high-quality-song the accuracy of load cells by using meticulously studying and correcting the sign output. This results in a marked discount in noise and an boom in the sign-to-noise ratio, which is critical for specific measurements.

Furthermore, eTAZ systems atone for environmental variables that usually affect load cell performance, including fluctuations in temperature. Smart algorithms adjust the readings accordingly, ensuring the load cell’s output remains steady under various conditions. By incorporating remote monitoring capabilities, eTAZ systems revolutionize load cell management, allowing for real-time data collection and analysis.

Practical Applications of Load Cell Sensors

In the dynamic geographical regions of enterprise and era, load cell sensors function the backbone for a myriad of important programs. Within the automotive sector, they play a pivotal position in assessing automobile weight distribution, ensuring highest quality overall performance and safety. Aerospace engineers rely on these sensors for structural testing, monitoring stresses and hundreds that aircraft components undergo. In the field of agriculture, load cells make a contribution to the efficiency and precision of system, from measuring the amount of feed disbursed to farm animals to ensuring uniform application of fertilizers. The healthcare industry blessings from load mobile era inside the improvement of superior medical devices, facilitating affected person weight monitoring and assisting in problematic surgical processes via presenting particular pressure measurements.

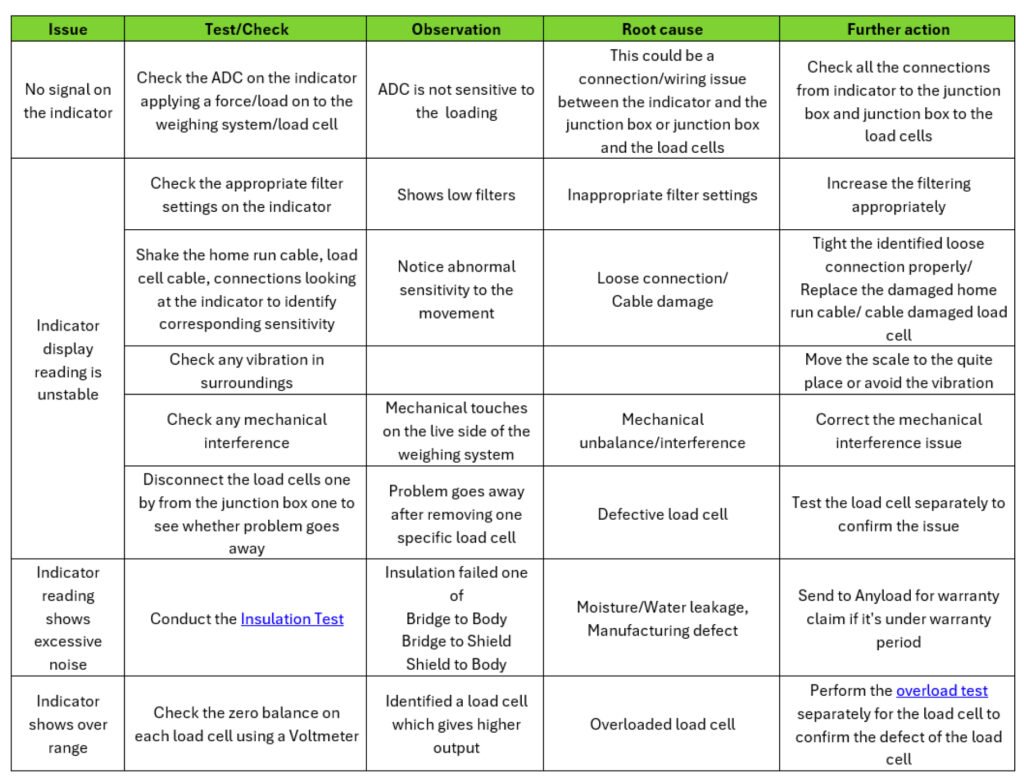

Troubleshooting Common Load Cell Issues

Encountering problems with load cellular sensors isn’t always unusual, with common issues together with sign waft, bodily overload, susceptibility to temperature modifications, and electrical noise interference. To efficaciously address those demanding situations, step one entails diligent calibration and habitual preservation tests.

“These practices not only ensure the sensor’s overall performance is optimized but also extend its operational lifespan.”

Regular inspections can uncover early symptoms of damage or harm, preventing more extreme headaches down the road. Moreover, mitigating environmental influences performs a essential position in preserving load cellular accuracy. Implementing measures to protect the sensor from extreme temperature variations, moisture, and vibrations can appreciably lessen the probability of malfunctions. It’s also beneficial to look at the electric setup for potential resources of interference and make sure that cable connections are stable and nicely shielded.

The Future of Load Cell Technology

As we gaze into the horizon of technological improvements, promising advancements are marking the trajectory of load mobile generation to enhance performance, accuracy, and integration capabilities. Researchers expect recent materials and production techniques to yield load cells that are more resilient to harsh environments and capable of delivering exceptional levels of precision.

“These advancements are especially essential as industries seek greater state-of-the-art dimension answers in an increasing number of complicated and demanding settings.

Researchers predict that emerging traits in miniaturization will supply smaller, more efficient load cells, opening the door to novel applications where space and weight are limiting factors. This shift is important for sectors consisting of clinical gadgets and wearable generation, where compactness without sacrificing accuracy is paramount.

Moreover, the fusion of load cells with wi-fi and Internet of Things (IoT) era is placing the stage for a revolution in statistics collection and analysis. This connectivity promises to empower industries with the capability to perform actual-time monitoring and adjustments, thereby improving operational efficiencies and predictive preservation abilties.

Cloud-based analytics systems can redefine how measurement data is used by integrating load cell statistics, enabling a smarter, data-driven decision-making approach across a wide range of sectors.

In essence, the path ahead for load cellular era is one in all innovation, marked through the pursuit of extra accuracy, adaptability, and connectivity.

FAQS

Q: What mechanism allows load cells to measure weight and pressure?

A: The core mechanism in the back of load cells entails pressure gauges that locate deformation.

The load cell deforms under weight or force, causing changes in electrical resistance in the strain gauges, which are then transformed into a readable electric signal corresponding to the applied pressure.

Q: Are there particular load cells for different styles of measurements?

A: Yes, there are several sorts tailor-made to various size eventualities.

People use compression load cells to measure forces implemented downwards, while tension load cells measure pulling forces.

Shear beam and bending beam load cells are ideal for precise environments, with every kind offering wonderful benefits in accuracy and application suitability.

Q: What steps should be taken to resolve troubles with load cells?

A: Effective troubleshooting includes carrying out ordinary calibrations and inspections to catch and mitigate early symptoms of trouble.

Ensuring the load cell is protected from destructive environmental situations like temperature extremes and vibrations, and ensuring effective hookup and shielding of electric components can also prevent common issues.